K-WANG

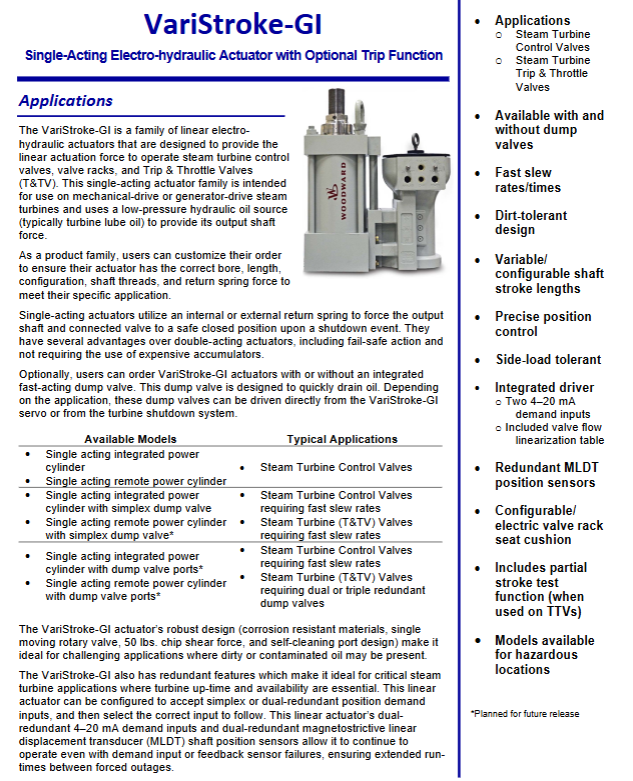

WOODWARD VariStroke GI single acting electro-hydraulic actuator

WOODWARD VariStroke GI single acting electro-hydraulic actuator

The core positioning is a high reliability single acting electro-hydraulic actuator designed specifically for steam turbine valve control, supporting redundant configuration and on-site customization

Application scenarios and core values

(1) Main applications

Control objects: steam turbine control valves, valve racks, trip throttle valves (T&TV)

Adaptation equipment: Mechanical or generator driven steam turbine

Additional scenario: retrofit replacement of old servo systems/manual valves to solve the problems of difficult spare parts and complex calibration

(2) Core values

Safety guarantee: single acting design+built-in reset spring, automatically closes the valve in case of failure, meeting the safety requirements for failure

Convenient operation and maintenance: Factory pre assembly testing, on-site configuration through service tools, reducing installation and calibration time

Environmental adaptation: Anti fouling design is suitable for harsh oil environments, and the ability to withstand lateral loads solves the problem of shaft seal leakage

Flexible adaptation: supports multiple stroke and aperture selections, optional discharge valve configuration, adapts to different valve control requirements

Product Core Features

(1) Structure and redundancy design

Core structure: Single acting power cylinder (optional internal/external reset spring)+integrated electronic drive module+rotary servo valve+dual redundant MLDT position feedback sensor

Redundancy function: dual 4-20mA demand input (supports single channel/dual channel average/high/low mode), dual MLDT position feedback, can still operate normally even if a single component fails

Configuration method: Connect the computer service tool through the RS-232 interface to configure functions such as travel, linearization parameters, and soft stop on site

(2) Key functional highlights

Anti fouling design: using corrosion-resistant materials, single movement rotary valve, 50 pound chip shear force, and self-cleaning port design, suitable for turbine lubricating oil environments containing impurities and sludge

Side load tolerance: Supports continuous side load up to 10% of the actuator output force, reducing shaft seal wear and oil leakage through high-precision bearings and special sealing technology

Soft stop function: The deceleration point above the valve seat can be configured to slow down the valve closing speed and extend the service life of the valve and valve seat

Quick release valve option: optional integrated Simplex quick release valve (or only reserved port), supporting direct drive of turbine shutdown system to achieve quick pressure relief

T&TV specific configuration: supports lifting commands, partial stroke testing, suitable for trip throttle valve applications, can provide valve position feedback through analog/discrete signals

(3) Product configuration type

Configuration Type Core Features Applicable Scenarios

Single acting integrated power cylinder with compact structure and built-in reset spring for conventional turbine control valve

Single acting remote power cylinder and servo separation installation space limited scenario

Single acting integrated power cylinder with quick release valve and Simplex release valve, regulating valve/T&TV that requires high-speed switching for quick pressure relief

Single acting integrated power cylinder with exhaust valve port reserved exhaust valve interface, supporting high critical applications (requiring dual/triple redundant tripping) with user provided redundant tripping components

Key specification parameters

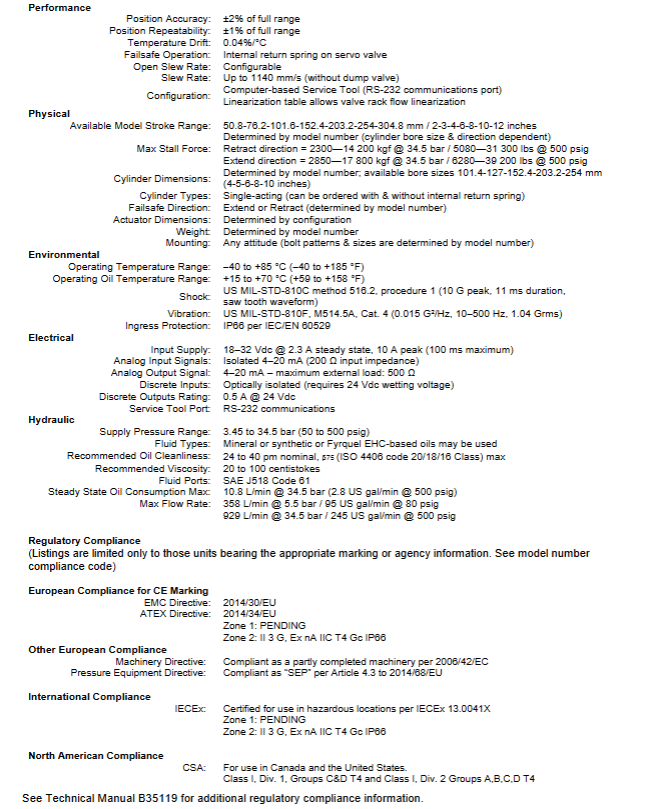

(1) Performance parameters

Parameter values

Positioning accuracy ± 2% of full range

Positioning repeatability accuracy ± 1% of full range

Temperature drift 0.04%/℃

The built-in reset spring of the fail safe servo valve forces the valve to close

The speed of opening/closing the sled can be configured, with a maximum of 1140mm/s (without discharge valve)

Partial itinerary testing support (T&TV application)

Linearization function supports valve flow linearization table configuration

(2) Physical parameters

Parameter details

Travel range 50.8mm (2 inches), 76.2mm (3 inches), 101.6mm (4 inches), 152.4mm (6 inches), 203.2mm (8 inches), 254mm (10 inches), 304.8mm (12 inches)

Aperture specifications 101.4mm (4 inches), 127mm (5 inches), 152.4mm (6 inches), 203.2mm (8 inches), 254mm (10 inches)

Maximum stall force retraction direction: 2300-14200kgf@34.5bar ( 5080-31300lbs@500psig ); Extension direction: 2850-17800kgf@34.5bar ( 6280-39200lbs@500psig )

Installation method at any angle (bolt style and size depend on the model)

Protection level IP66 (IEC/EN 60529)

(3) Environmental and electrical parameters

Category parameter values

Environmental parameters Working environment temperature -40 ℃~+85 ℃ (-40 ℉~+185 ℉)

Working oil temperature+15 ℃~+70 ℃ (+59 ℉~+158 ℉)

The impact resistance performance complies with US MIL-STD-810C method 516.2 (10G peak, 11 millisecond duration)

Anti vibration performance meets US MIL-STD-810F M514.5A (0.015 G ²/Hz, 10-500Hz)

Electrical parameters: Supply voltage 18-32Vdc (steady-state current 2.3A, peak 10A/100ms)

Analog input isolation 4-20mA (input impedance 200 Ω), dual redundancy

Analog output 4-20mA (maximum external load 500 Ω)

Discrete input optical isolation (requires 24Vdc wetting voltage)

Discrete output 0.5A@24Vdc

Service tool port RS-232 communication

(4) Hydraulic parameters

Parameter requirements

Working pressure range: 3.45 bar~34.5 bar (50 psi~500 psi)

Oil type: mineral oil, synthetic oil, or Fyrquel EHC base oil

Recommended maximum oil cleanliness ISO 4406 code 20/18/16 level (nominal 24-40 μ m, β 75)

Recommended oil viscosity is 20-100 centixtles

Interface standard hydraulic ports comply with SAE J518 Code 61

Steady state oil consumption maximum 10.8L/ min@34.5bar (2.8 US gallons per minute @ 500pg)

358L/min at a maximum flow rate of 5.5 bar (95 US gallons per minute at 80 PSI); 929L/min at 34.5 bar (245 US gallons per minute at 500 sig)

Compliance certification

Regional/Standard Certification Content

European (CE) EMC Directive 2014/30/EU; ATEX Directive 2014/34/EU (Zone2: II 3 G Ex nA IIC T4 Gc IP66)

Other European Standard Machinery Directive 2006/42/EC (partially completed machinery); Pressure Equipment Directive 2014/68/EU (SEP category)

International IECEx certification (certificate IECEx 13.0041X, Zone 2: II 3 G Ex nA IIC T4 Gc IP66)

North American CSA certification (Class I, Div.1 Groups C&D T4; Class I, Div.2 Groups A-D T4), applicable to the United States and Canada

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923