K-WANG

Meggitt Vibro meter VM600Mk2 Mechanical Protection and Condition Monitoring System

Meggitt Vibro meter VM600Mk2 Mechanical Protection and Condition Monitoring System

The Meggitt Vibro meter VM600Mk2 is a second-generation mechanical protection and condition monitoring system upgraded from the first generation VM600 (launched in 2000). It retains backward compatibility (can be mixed with first generation modules, reuse racks and power supplies) and integrates protection and condition monitoring functions through the MPC4MK2 module. It supports 4 vibration channels and 2 speed/phase channels, with SIL 2 functional safety certification, IEC 62443 network safety compliance, API 670 standard compatibility and other features. It also adds 5 epoxy sealed relays and graphical configuration software (with a 50% increase in configuration efficiency) to adapt to scenarios such as gas turbine combustion dynamic monitoring and rotating machinery vibration protection. More than 8000 sets of first generation systems have been installed worldwide, and the second generation further meets the requirements. The demand for safety, integration, and ease of use in the power, oil, and gas industries.

Background and core positioning of product iteration

Key project information

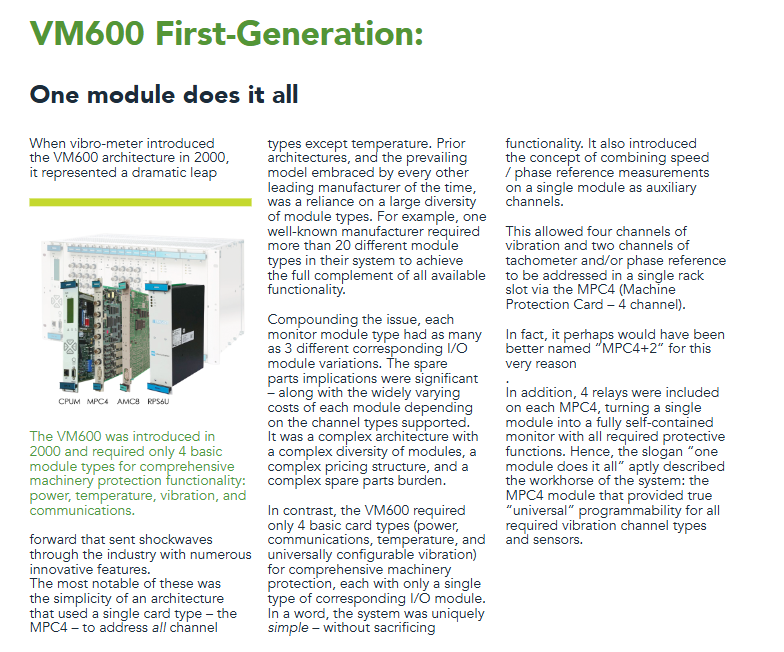

Innovation points of the first generation VM600 (2000): ① Single MPC4 module covers 4 vibration channels and 2 auxiliary channels; ② Physical separation of protection and CM functions (MPC4 protection+XMV16/XC16 CM); ③ Only 4 types of basic modules, simplified spare parts; ④ API 670 Compliance

Upgrade motivation 1. Network security requirements: to address industrial cyber threats and meet the IEC 62443 standard; 2. Function integration: Solve the problems of asynchronous first generation protection and CM data, as well as duplicate configuration; 3. Component availability: Some first generation electronic components are facing obsolescence; 4. Industry standard upgrade: API 670 version 6 update, SIL functional safety requirements popularized

The second generation core positioning retains the compatibility of the first generation while enhancing safety compliance, integration, and ease of use, adapting to the extreme environmental monitoring needs of the power, oil, and gas industries

Core modules and key parameters

1. Core module functions

Module model, core functions, key specifications

MPC4MK2 universal vibration monitoring, protection+CM integrated 4-channel dynamic signal input, 2-channel speed/phase/DC input; 5 epoxy sealed relays; Support SIL 2; Share sensor signals with XMV16

CPUMMk2 communication and rack control support protocols such as Modbus TCP/RTU, Profinet, etc; Physical key lock+password protection; IEC 62443 Compliance

RLC16Mx2 relay expands with 16 epoxy sealed relays; Support NO/NC wiring; Software configuration on/off status

XMV16 (reserved) pure state monitoring 16 channels, compatible with third-party protection system docking

XMC16 (reserved) gas turbine combustion dynamic monitoring adapted for low NOx gas turbines, monitoring combustion pulsation pressure

2. Key performance parameters

Channel capability: MPC4MK2 supports 4 vibration channels and 2 auxiliary channels per module, with a maximum of 12 modules (72 channels) per rack

Relay configuration: MPC4MK2 includes 5 relays (4 from the first generation), RLC16MM2 expansion includes 16 relays, all of which are epoxy sealed

Compliance standards: API 670 (5th edition compatible, participated in the development of 6th edition), SIL 2 functional safety, IEC 62443 network security, Class 2/Div 2 hazardous area adaptation

Software efficiency: VibroSight Protect graphical configuration software reduces configuration time by more than 50%, supports drag and drop, copy and paste

Core Upgrade and Advantages

1. Function integration upgrade

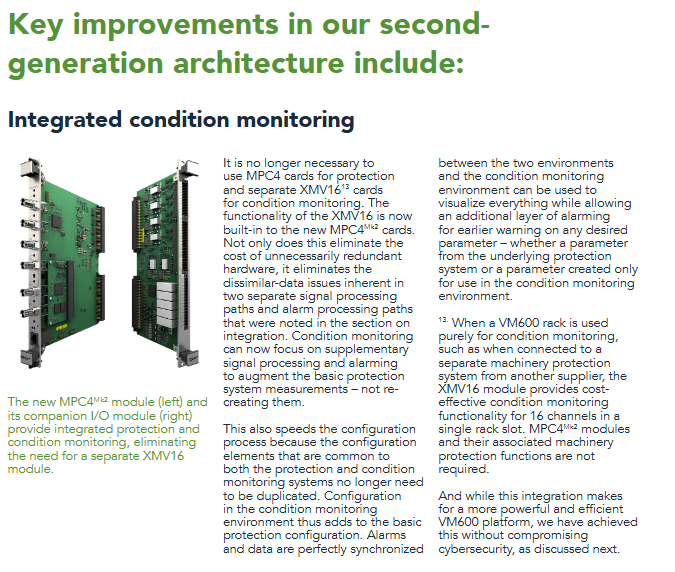

Integrated protection and status monitoring: MPC4MK2 has XMV16 CM function built-in, eliminating the need for separate CM module configuration, solving the problems of first generation data synchronization and configuration duplication

Data synchronization: Protecting complete synchronization with CM alarms and measurement data, facilitating event sequence reconstruction

Extended measurement: supports 10+measurement types such as air gap, magnetic flux, envelope demodulation, etc., and can add software customized alarms

2. Security and compliance upgrades

Functional safety: The module is designed according to SIL 2 (SIL 2 version will be released in 2022) and supports Safety Instrumented Systems (SIS) applications

Network security: dual protection of physical lock (CPUMMK2 key lock+MPC4MK2 configuration button) and password to prevent unauthorized configuration changes

Environmental protection: Relay epoxy sealing enhances adaptability to harsh environments

3. Usability upgrade

Configuration optimization: graphical interface replaces the first generation text configuration and supports batch copying of channel settings

Backward compatibility: can be mixed with first generation modules, reusing rack, power, and sensor wiring to avoid "overall replacement"

Easy maintenance: Keep XMV16/XMC16 modules, existing CM functions do not need to be upgraded

Applicable scenarios and industry adaptation

Application scenario adaptation device core value

Monitoring of low NOx/DLE gas turbine combustion dynamic pulsation, protecting the combustion chamber and reducing NOx emissions

Rotating machinery protects compressors, pumps, motors, and fans from vibration, speed, and axial displacement to prevent equipment damage

The thermal power/nuclear power/hydropower equipment in the power industry meets the safety requirements of the power grid and supports redundant configuration

Oil and gas offshore platforms, pipeline compressors API 670 compliant, suitable for hazardous area environments

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923