K-WANG

XYCOM XVME-100 memory module

XYCOM XVME-100 memory module

Product Overview and Core Positioning

Product definition: XYCOM XVME-100 is a single height (3U) VMEbus compatible memory expansion module for industrial control systems, designed to provide RAM, EPROM, mask ROM, or EEPROM storage expansion for VMEbus architecture systems, supporting flexible configuration and data backup.

Core values:

High compatibility: fully compliant with the VMEbus C1 standard, seamlessly integrated into the VMEbus system;

Flexible expansion: Dual storage group design, supporting multiple capacities and types of storage chips, adapting to different scene requirements;

Data security: onboard battery backup and undervoltage protection circuit to prevent data loss caused by power failure;

Independent configuration: Independent settings of storage group address, chip speed, backup power, and other parameters are achieved through jumper wires.

Applicable scenarios: VMEbus architecture devices that require reliable memory expansion, such as industrial automation control, military electronic equipment, embedded systems, etc.

Key specification parameters

(1) Core Performance Parameter Table

Specific specifications of the project

Storage capacity RAM/EPROM/Mask ROM: Maximum 1MB; EEPROM: Maximum 256KB

Design 2 storage groups (Bank1/Bank2), each with 4 32 pin JEDEC slots, supporting independent configuration

Compatible chip specifications and capacities: 8K × 8, 16K × 8, 32K × 8, 64K × 8, 128K × 8 (EEPROM limited to 32K × 8 and below);

Speed: 100ns, 150ns, 200ns, 250ns

Power requirements: Working power supply:+5V DC (typical 900mA, maximum 1A);

Backup power supply: onboard battery (1.4Ah, typical lifespan of 6 years) or+5V STDBY

Bus compatible with VMEbus C1 standard, A24 address space, DTB slave device

Physical specification 3U Form Factor (single height), size meets VMEbus standard

(2) Environmental and Reliability Parameter Table

Specific specifications of environmental category

Working temperature: 0 ° C~65 ° C (32 ° F~149 ° F)

Storage temperature -40 ° C~85 ° C (-40 ° F~158 ° F)

Humidity 5%~95% RH, non condensing (anti-static protection is required for extremely low humidity)

Altitude work: 0~3048m (10000ft); Storage: 0~15240m (50000ft)

Vibration (working) 5~2000Hz, peak acceleration 10g, peak to peak displacement 0.025mm (maximum)

Impact (working) 30g peak acceleration, 11ms duration

Core functions and design highlights

(1) Storage and configuration functions

Dual storage group independent configuration: Bank1 and Bank2 can set VME address, chip size, address modifier decoding, chip speed, and backup power type separately through jumper wires, supporting mixed use of chips of different specifications;

Multi type storage support: compatible with RAM, EPROM, mask ROM, EEPROM four storage types, EEPROM needs to support fast write/polling technology and TTL logic level;

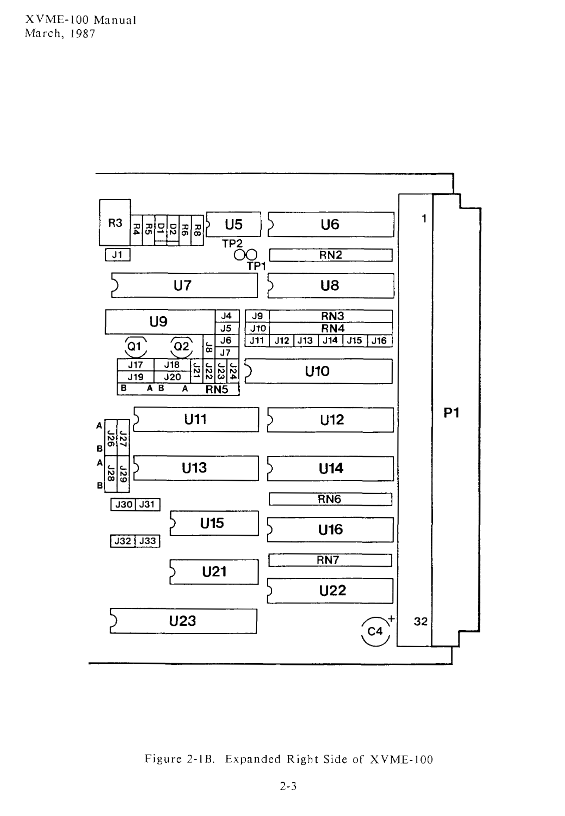

Flexible allocation of address space: Set the base address through J14-J24 (Bank1) and J16/J26-J33 (Bank2) jumpers, and the address space occupied by the storage group is 4 times the chip capacity, which needs to be aligned to the 4 times capacity boundary.

(2) Data protection mechanism

Undervoltage protection: Equipped with a built-in power monitor, the storage chip is automatically disabled when the+5V voltage is lower than 4.75V to prevent data writing errors. The SYSRESET * drive signal can be optionally enabled;

Dual options for backup power: supports onboard battery backup (compatible with low-power RAM chips) or VMEbus+5V STDBY backup, switched via J34/J35 jumper;

Data anti write design: automatically cuts off the write path of the storage chip in case of power failure, combined with battery backup to ensure long-term storage of RAM data.

(3) Bus and interface characteristics

VMEbus signal compatibility: supports IACKIN */ACKOUT * daisy chain and BUS GRANT signal direct connection, complying with the address, data, and control signal definitions of VMEbus C1 standard;

P1 connector interface: 3-row pin design, including address bus (A01-A23), data bus (D00-D15), control signals (AS *, DS0 */DS1 *, DTACK *, etc.), and power pins;

Status indication: Each storage group is equipped with a green LED that lights up instantly when accessed, providing visual feedback on the working status.

Installation and configuration process

(1) Key items for jumper configuration

Configure Category Jumper Position Core Function

Address/chip size Bank1: J14/J17-J24/J50-J52;

Bank2: J16/J26-J33/J47-J49 Set VME base address (A15-A23) and chip capacity (8K × 8~128K × 8)

Address modifier decoding Bank1: J10-J13;

Bank2: J9/J12/J15 Configure privileged access (super user only/all users), data/program space access permissions

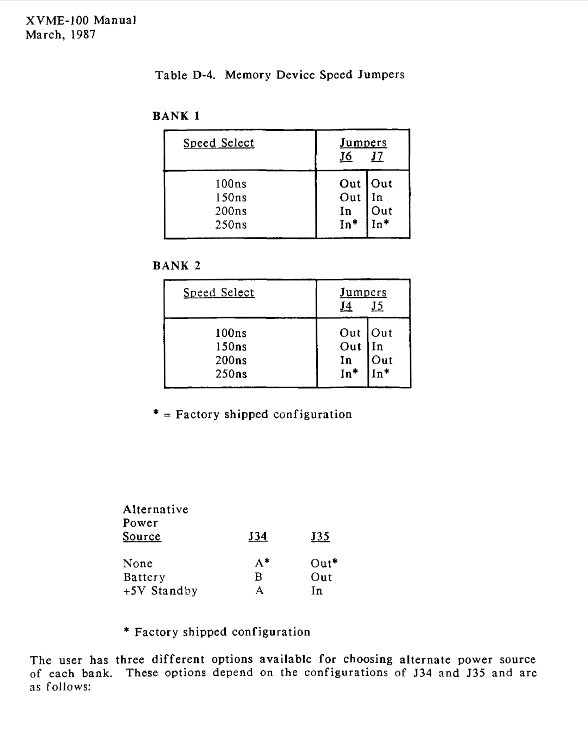

Chip speed selection Bank1: J6-J7;

Bank 2: J4-J5 matching storage chip speed (100ns/150ns/200ns/250ns)

Definition of memory chip pins Bank1: J40-J46;

Bank2: Pin definitions for adapting J2/J3/J25/J36-J39 to different types of storage chips (such as EPROM/RAM pin differences)

Select J34-J35 for backup power and switch between battery backup/+5V STDBY backup/no backup mode

(2) Installation steps

Chip installation: In the power-off state, configure the corresponding jumper according to the storage type, align the storage chip with the slot gap direction, evenly insert it into the 32 pin slot with force, and ensure that the pins are fully in contact;

Rack deployment: Align the module with the VMEbus rack rail, slowly push it in until the connector is fully engaged, and secure the front panel with screws. Each module occupies one 3U slot;

Optional 6U panel installation: If you need to adapt to a 6U rack, you can replace the XVME-945 6U front panel kit and transfer the handle and identification plate according to the manual steps;

Calibrate power monitor: It has been calibrated at the factory. If recalibration is required, adjust the POT R3 potentiometer with a 4.75V reference power supply to ensure accurate triggering threshold for undervoltage protection.

Safety and usage precautions

Battery safety: Short circuit, charging, reverse connection, welding or heating of batteries are prohibited. Waste should be treated as industrial waste to avoid high temperature and contact with metal surfaces;

Static electricity protection: When operating modules and storage chips, it is necessary to release human static electricity, especially CMOS RAM chips are sensitive to static electricity;

Installation taboos: It is forbidden to plug and unplug modules with power on. When inserting, avoid applying too much force to bend the pins and ensure that the module is aligned with the rack rails;

Special requirements for EEPROM: EEPROM must support fast write/polling technology and must use TTL logic level, otherwise it may cause abnormal operation.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923