K-WANG

Woodward easyYgen-3000 series (Package P1) generator set controller

Woodward easyYgen-3000 series (Package P1) generator set controller

Overview

The Woodward easyYgen-3000 series generator controller is an advanced device designed specifically for controlling generator sets, providing comprehensive monitoring, protection, and automation functions. This manual (37223E version) provides a detailed introduction to the installation, wiring, and technical specifications of two models, easyYgen-3200 (plastic casing) and easyYgen-3100 (metal casing). The software version is 1.10xx, suitable for products with part numbers 8440-1816, 8440-1817, 8440-1818, and 8440-1831.

Safety Warning and Important Reminder

Critical safety warning

Independent overspeed protection: The prime mover must be equipped with an overspeed (over temperature or over pressure) shutdown device that is completely independent of the controller to prevent equipment damage or personnel injury caused by the failure of the governor or control system.

Unauthorized modifications are prohibited: Any unauthorized modifications beyond the prescribed mechanical, electrical, or operational limitations may result in personal injury and/or property damage, and render product warranty and certification invalid.

Electrostatic protection: The electronic control unit contains electrostatic sensitive components, and before operation, body static electricity must be released by contacting the grounding surface to avoid contact with components and conductors on the printed circuit board.

Important Definition

Warning: Indicates a potentially dangerous situation that, if not avoided, may result in death or serious injury.

Attention: Indicates a potential hazardous situation, which may result in equipment damage if not avoided.

Explanation: Provide other useful information that does not belong to the warning or caution category.

Installation and mechanical characteristics

Shell type

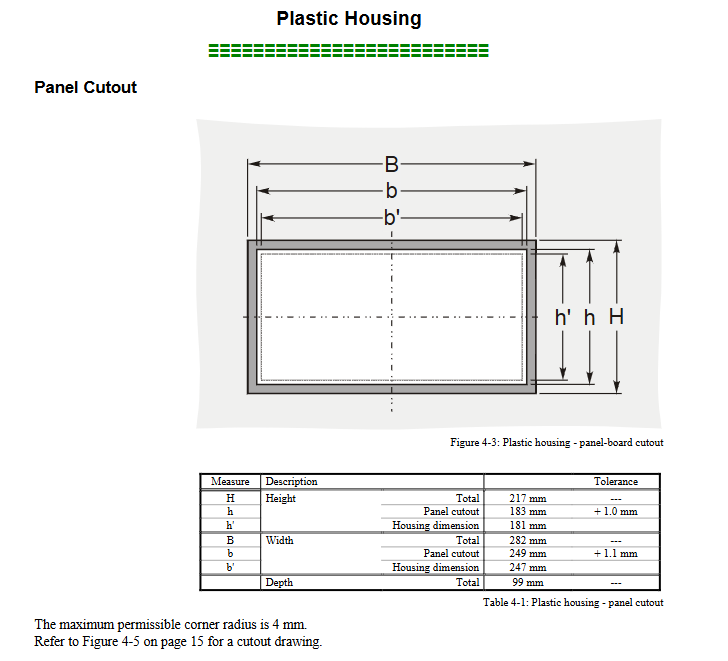

Plastic casing (easyYgen-3200)

Used for front panel flat installation with graphic LCD display screen

Protection level: IP54 when installed with fixtures, can be raised to IP66 when installed with screw kits

Overall dimensions: 282 × 217 × 99 mm

Panel opening size: 249 (+1.1) × 183 (+1.0) mm

Metal casing (easyYgen-3100)

Used for installing switch cabinet backboards without display screens

Protection level: IP20

Size: 249.6 × 227.4 × 84.1 mm

Installation key points

Plastic shell installation: can be installed using fixtures or screw kits, using all 12 screws can achieve IP66 protection level

Metal shell installation: Installed on the back panel of the switchgear using 4 screws with a maximum diameter of 6mm

Panel thickness limit: If the panel thickness exceeds 2.5mm, screws with a length equal to the panel thickness plus 4mm must be used

Detailed explanation of electrical connections

Power supply

Voltage range: 8-40 VDC

Protective grounding: A protective grounding wire with a cross-sectional area of ≥ 2.5mm ² must be connected

Recommended protective device:

Fuse: NEOZE D01 6A or equivalent product

Miniature circuit breaker: 6A/C type (such as ABB S271C6)

Voltage measurement (FlexRange technology)

Input type: Two sets of input terminals, 100V and 400V, are provided and cannot be used simultaneously

Configuration rules:

Secondary rated voltage 50-130V: using 100V input terminal

Secondary rated voltage 131-480V: using 400V input terminal

Wiring method: Supports multiple configurations including 3-phase 4-wire, 3-phase 3-wire, 1-phase 3-wire, and 1-phase 2-wire (phase neutral or phase phase)

current measurement

Variable ratio selection: supported /1A and /5A two variable ratios

Accuracy level: Level 1

Safety precautions: Before disconnecting the equipment, the secondary side of the current transformer must be short circuited

Grounding requirement: One end of the secondary side of the current transformer should be grounded near the CT

Power measurement and power factor

Power direction indication:

Actual power of generator: positive values indicate power generation, negative values indicate reverse power

Power factor: Positive values indicate inductive/lagging, negative values indicate capacitive/leading

Definition of power factor: the ratio of actual power to apparent power, with a pure resistance circuit of 1.00, inductive load as lagging power factor, and capacitive load as leading power factor

Digital input/output

Digital input: 12 channels, electrically isolated, configurable as positive or negative polarity signal

Important Warning: DI01 "Emergency Stop" is only a signal input, and the emergency stop function must be independently implemented outside the controller

Relay output: 12 channels, programmable (via LogicsManager function)

Contact type: normally open (NO) and switchable contacts

Load capacity: Universal type 2A@250VAC , 2A@24VDC

Analog input (FlexIn technology)

Sensor type: Supports 0/4-20mA, 0-500 Ω resistors, and VDO sensors

Wiring method:

Dual line sensor: accuracy ≤ 1% (resistance) or ≤ 1.2% (current)

Single line sensor: accuracy ≤ 2.5% (ensure that the voltage difference between the chassis grounding and PE is ≤ ± 2.5V)

Recommended sensors: VDO series

interface configuration

RS-485 interface: supports half duplex and full duplex Modbus communication

RS-232 interface: standard serial interface, electrically isolated

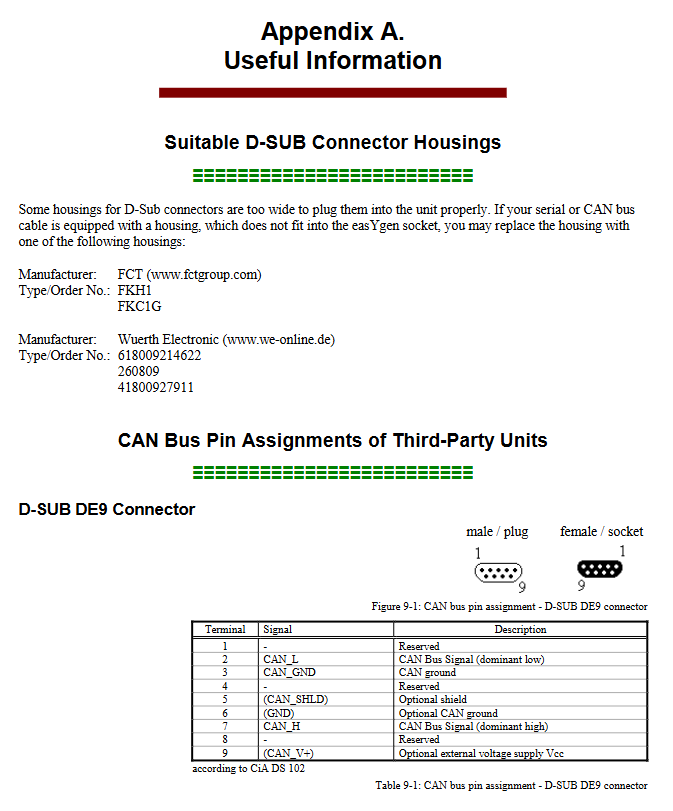

CAN bus interface: Two independent CAN channels (FlexCAN technology)

Recommended cable: shielded twisted pair (such as Lappkabel Unitronic LiyCY)

Terminal resistor: Both ends need to be connected to a 120 Ω terminal resistor

Maximum length: related to baud rate (25m at 1Mbps, 2500m at 20kbps)

Overview of Technical Data

measure performance

Voltage measurement:

100V input: rated 69/120VAC, maximum 86/150VAC

400V input: rated 277/480VAC, maximum 346/600VAC

Accuracy: Level 1, linear range 1.25 x rated value

Current measurement:

Accuracy: Level 1

Linear range: 3 times rated value on the generator side, approximately 1.5 times rated value on the grid/ground side

Analog input: 11 bit resolution, supporting 0-20mA and 0-500 Ω inputs

environmental adaptability

Working temperature: -20 ° C to 70 ° C

Storage temperature: -30 ° C to 80 ° C

Humidity: 60 ° C, 95% relative humidity, tested for 5 days

Vibration: Complies with EN 60255-21-1/-3, MIL-STD 810F and other standards

Shock: 40G, sawtooth pulse, 11ms

Certification and Protection

Electrical safety: CE mark, UL certification (for ordinary places)

Ship certification: LR (Lloyd's Register), ABS (American Bureau of Shipping)

Protection level: Plastic shell IP54/IP66, metal shell IP20

Electromagnetic compatibility: compliant with relevant EN standards

Precision reference conditions

To ensure measurement accuracy, it is recommended to operate under the following conditions:

Input voltage: sine rated voltage

Input current: sine rated current

Frequency: Rated frequency ± 2%

Power supply: rated voltage ± 2%

Power factor: 1.00

Environmental temperature: 23 ° C ± 2K

Preheating time: 20 minutes

Special application precautions

Ship application

Power filtering: When used in bridge and deck areas, EMI filters (such as TIMONTA FSS2-65-4/3) should be equipped for power input

Additional safety devices: Additional independent safety protection devices are required to meet classification society regulations

Certification: easyYgen has obtained type certification from Lloyd's Register of Shipping

Electrostatic protection

Before operating the electronic control unit, it is necessary to release body static electricity by touching the grounded metal surface

Avoid wearing synthetic clothing and try to wear cotton clothing as much as possible

Keep plastic, vinyl and foam materials away from the control unit and work area

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923