K-WANG

Woodward easyYgen LS-6XT series circuit breaker control unit

Woodward easyYgen LS-6XT series circuit breaker control unit

Basic Information

Product model easyYgen LS-6XT series (representative model LS-612XT-P1/P2)

Core positioning circuit breaker control, dual system synchronous monitoring, fault alarm, logic expansion

Adaptation target engine generator set (GCB/MCB/GGB control)

Certification qualifications UL/cUL, CE, Lloyd's (ENV1/ENV2), ABS classification certification

System hardware and interface configuration

(1) Core interface parameters

Interface type specification details

The input voltage range of the power supply is 8-40Vdc. It is recommended to connect a 6A slow melting fuse in series, with a power consumption of about 6W

Voltage measurement (dual system) supports 3Ph4W/3Ph3W/1Ph3W/1Ph2W wiring; Measurement range 120/480/690Vac (PT secondary side)

Current measurement (dual system) supports L1/L2/L3 three-phase or single phase to ground measurement; CT input 1A/5A optional, system A occupies 6 terminals, system B occupies 2 terminals

Discrete Input (DI) 12 channel optical isolation, input voltage 8-40Vdc, supports NO/NC configuration; Can be extended to 32 channels (P2 model) through IKD module

Discrete Output (DO) 12 way relay, passive contacts, universal load 2A@250Vac /24Vdc; Can be extended to 32 channels (P2 model) through IKD module

Analog input (AI) 3 channels, supporting 0-2000 Ω (resistance type), 0/4-20mA (current type), 0-1V (voltage type), supporting Pt100/Pt1000/VDO sensors

Analog output (AO) 2 channels, supporting ± 20mA, ± 10V, PWM output, galvanic isolation, configurable filtering time constant

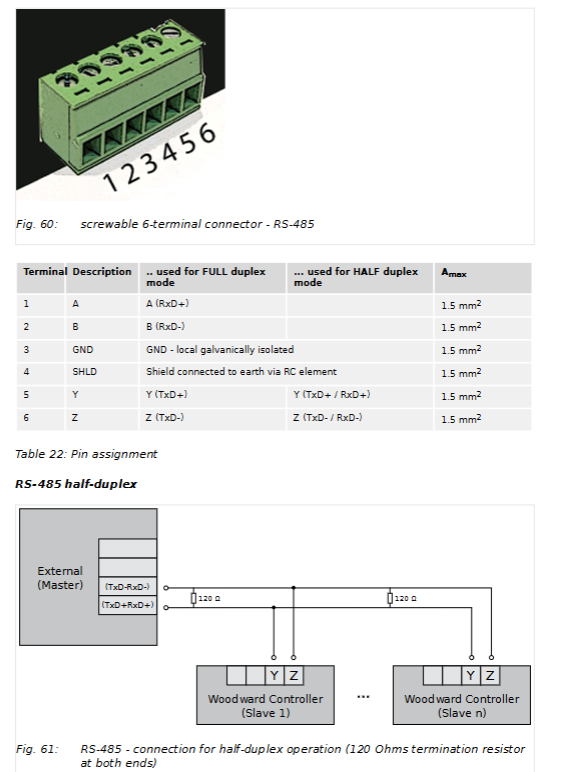

Communication interface RS-485: supports half/full duplex, with maximum transmission distance dependent on baud rate; USB 2.0: Service port, ToolKit connection; CAN Bus: Supports CANopen, up to 2500m (20kBaud); Ethernet: 3 RJ-45 ports, supporting 10/100Base-T, maximum transmission of 100m

(2) Structure and environmental specifications

Category specific parameters

The shell structure is made of metal material, with dimensions of 227 (width) x 250 (height) x 50 (depth) mm; the panel openings must comply with the drill plan

Protection level IP66 (screw installation), IP54 (fixture installation), IP20 (back)

Environmental tolerance working temperature -20 ° C~70 ° C, storage temperature -30 ° C~80 ° C; humidity 95%, no condensation (85% when ≤ 40 ° C)

Anti interference performance vibration: 5-100Hz sine sweep frequency (4G), 10-500Hz random vibration (1.04Grms); Shock: 40G sawtooth wave pulse (11ms)

Core functions and operations

(1) Core control function

Circuit breaker control: supports the closing/opening of CBA (main circuit breaker) and CBB (backup circuit breaker), can be configured with pulse (0.1-9.9s) or continuous output mode, supports automatic unlocking (Pre open pulse) function

Synchronous grid connection control: Monitor the voltage difference (0.50-20.00%), frequency difference (± 0.49Hz), and phase difference (± 60 °) of the dual systems, trigger grid connection after meeting the conditions, and support phase compensation (-180 °~180 °)

Dead bus closure: supports both A/B dual systems to be dead, one dead and one active scenario closure, detection threshold 0-30% rated voltage, delay 0-20s, supports multi device negotiation mechanism

Load transfer: Supports four modes: Open Transition, Closed Transition, Interchange, and Parallel

Fault decoupling: Monitor thresholds such as over/under frequency, over/under voltage, phase offset, df/dt, etc., and automatically disconnect the designated circuit breaker (CBA/BBB or both) upon triggering

(2) Programming and configuration methods

Configuration Method Operation Path Core Function

Local operation front-end panel (LCD+buttons) parameter viewing, mode switching, manual control of circuit breakers, alarm confirmation

Remote Panel RP-3000XT (Ethernet) fully functional visual operation, supporting Full/Annunciator/Off modes

PC configuration ToolKit software (Windows 7/8.1/10) includes full parameter configuration, logic programming, analog processing, data trend monitoring, and log export

LogicsManager supports logical combinations such as AND/OR/NAND, and can customize discrete I/O associations and alarm triggering conditions

Analog Manager supports 8 types of sensor curves, 2 custom tables (9-point calibration), and unit conversion (° C → ° F, bar → psi) for analog processing

(3) Alarm and Log

Alarm level: Level 6 (A-F), Level A/B for warning (no trip), Level C-F for shutdown (disconnect circuit breaker)

Event log: records 300 system events (including timestamps), supports FIFO storage, and can be manually cleared

Alarm monitoring: covering 20+types of alarms such as voltage/frequency exceeding limits, phase rotation mismatch, I/O faults, communication abnormalities, etc

Key configuration parameters

(1) Permission and password grading

Permission level, access method, core permissions

CL0 (user level) no password, only view data, confirm alarms

CL1 (basic level) password 0001 modification of non critical parameters (such as language, unit)

CL3 (debugging level) password 0003 full parameter configuration, logic programming, factory reset

CL5 (Super Debugging Level) Password 0500 Firmware Update, Advanced Parameter Configuration

Temporary permission algorithm generates password for temporary access to corresponding level, automatically exits upon timeout

(2) Example of Core Function Configuration Parameters

Parameter Category Key Parameters Default Value Configuration Range

Synchronous Control Voltage Difference Threshold (CBA) 5.00% 0.50-20.00%

Frequency difference threshold (CBA) ± 0.18Hz -0.49-0.49Hz

Phase difference threshold (CBA) ± 7.0 ° -60.0-60.0 °

Dead bus control detection threshold 10% 0-30%

Closing delay 5.0s 0.0-20.0s

Communication configuration CANopen baud rate 125kBaud 20-1000kBaud

Ethernet IP Mode Static/Dynamic (DHCP)

Load Transfer Time (CBA) ↔ CBB) 1.00s 0.50-99.99s

Key issue

Question 1: How is the dual circuit breaker (CBA/BBB) control function of LS-6XT implemented, and what are the core configuration differences?

Answer: The dual circuit breaker control is achieved through the "CBA/BBB mode", and the core is the independent control and linkage logic of the two circuit breakers: ① Hardware configuration: CBA corresponds to the main circuit breaker, CBB corresponds to the backup/load circuit breaker, both support closing/opening pulse/continuous control, and can be configured with automatic unlocking (Pre open) function; ② Core differences: CBA focuses on main circuit grid connection, dead bus closure, and system A decoupling, while CBB focuses on backup circuit switching and system B associated control, with CBA having higher closure priority than CBB; ③ Linkage logic: supports load transfer (four modes), synchronous grid connection linkage (CBB synchronization after CBA closure), and selective disconnection in case of failure (such as CBA disconnection in case of system A failure and CBB disconnection in case of system B failure); ④ Configuration points: It is necessary to switch between "CBA"/"CBA/BBB" modes through parameter 9018 (Breaker mode), and configure the synchronization threshold, dead bus condition, and linkage delay of both modes separately.

Question 2: How to configure and use the extended I/O (IKD module) of LS-6XT, and what extension scenarios are supported?

Answer: The IKD module is an external I/O expansion solution, with the following core configurations and scenarios: ① Supported module types: IKD1 (8DI+8DO), IKD-IN-16 (16DI), IKD-OUT-16 (16DO), P1 model supports 2 IKDs (16DI+16DO), P2 model supports 4 IKDs (32DI+32DO); ② Connection method: Connected through CAN1 bus, CAN baud rate and module address need to be configured, shielded cable exposed length ≤ 25mm; ③ Configuration path: "Configure Input/Output → External Discrete Input/Output" in ToolKit, can set DI alarm level, delay time, and logical association of DO; ④ Extended scenarios: Suitable for complex systems that require more discrete signal acquisition (such as multi-sensor alarms) or output control (such as multi actuator linkage), such as multi loop state monitoring in ship power systems and multi device linkage control in industrial units.

Question 3: What is the core logic and safety mechanism of the synchronous grid connection and dead bus closure function of LS-6XT?

Answer: Both are the core functions of circuit breaker closure, and the logic and safety mechanism are as follows: ① Synchronous grid connection logic: Real time monitoring of dual system voltage/frequency/phase, meeting preset thresholds (voltage difference ≤ 20%, frequency difference ≤± 0.49Hz, phase difference ≤± 60 °) and continuously setting time (default 3s), triggering closure; Supports two synchronization modes: "slip frequency" and "phase matching", which can offset transformer phase offset through phase compensation; ② Dead bus closure logic: detects that the system voltage is below the threshold (0-30% rated voltage) and has a continuous delay time (0-20s), triggering after meeting the "no other device closure request" (multi device negotiation), supporting three scenarios: A dead B dead, A dead B live, A live B dead; ③ Security mechanism: Verify phase sequence consistency (CW/CCW) before synchronous grid connection, and block closure if inconsistent; The closure of the dead bus requires the "Enable close" logic to be enabled through LogicsManager, and there should be no C/F level alarms; In multi device scenarios, using "device number priority" to avoid simultaneous closure and automatically releasing permissions after closure failure ensures system security.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923