K-WANG

YASKAWA 1000 series frequency converter

YASKAWA 1000 series frequency converter

Core Overview

This document is the Spanish technical manual (manual number TOSP C710606 22B) for the Yaskawa V1000 series vector controlled compact frequency converter (model CIMR-VU), covering 200V single/three-phase (0.1-18.5kW) and 400V three-phase (0.2-18.5kW) models. The core provides guidance around the entire life cycle of the equipment, including receiving inspection, mechanical/electrical installation, programming start-up, troubleshooting, regular maintenance, peripheral equipment adaptation and other key contents. It emphasizes safe operation norms and precise parameter configuration, supports the control of ordinary induction motors and permanent magnet synchronous motors (PM), and provides comprehensive technical support for installation, commissioning, daily operation and maintenance, and fault resolution in industrial scenarios.

Detailed analysis of core chapters

Basic Information and Security Principles of Documents

Basic Information

Product positioning: Vector controlled compact frequency converter, suitable for 7 typical industrial applications such as pumps, conveyors, fans, compressors, cranes, etc.

Voltage and power range: 200V single-phase (0.1-5.5kW), 200V three-phase (0.1-18.5kW), 400V three-phase (0.2-18.5kW).

Document purpose: To guide users in correctly installing, operating, and maintaining equipment, and to clarify that users need to pass on the manual to the end user.

Copyright Notice: All rights reserved by Yaskawa Electric in 2008. Reproduction and dissemination are prohibited without written permission. Product information may change with upgrades, and we do not assume any responsibility for losses caused by misuse of information.

General Safety Principles

Security level definition: divided into four levels: "PELIGRO (fatal danger)", "ADVERTENCIA (serious danger)", "PRECAUCI Ó N (minor injury)", "AVISO (property damage)", clarifying the warning requirements for different risk scenarios.

Core safety regulations: After power failure, wait for ≥ 5 minutes for capacitor discharge (bus voltage<50Vdc); Prohibit live wiring or touching circuit boards; Only qualified personnel are allowed to operate; The equipment needs to be fixed on a non flammable material surface; Avoid using incompatible voltage power sources.

Special warning: When connecting the motor to the frequency converter, it is forbidden to plug or unplug it with power on; Prohibit conducting voltage withstand tests on frequency converters; Follow the electrostatic discharge (ESD) process; Single phase motors cannot be used in conjunction with this frequency converter.

Reception and Inspection

Core Inspection Process

Appearance and damage inspection: After receiving, confirm that the equipment is not damaged during transportation. If there is any damage, immediately contact the transportation party.

Model and nameplate verification: Confirm the model, input/output specifications, serial number and order consistency through the nameplate. The nameplate includes key information such as working mode (normal/heavy load), voltage level, output current, etc.

Model and protection type: The frequency converter provides two types of protection: IP20/open type (to be installed in a closed panel) and IP20/NEMA1 type (wall mounted), which need to be selected according to the installation scenario.

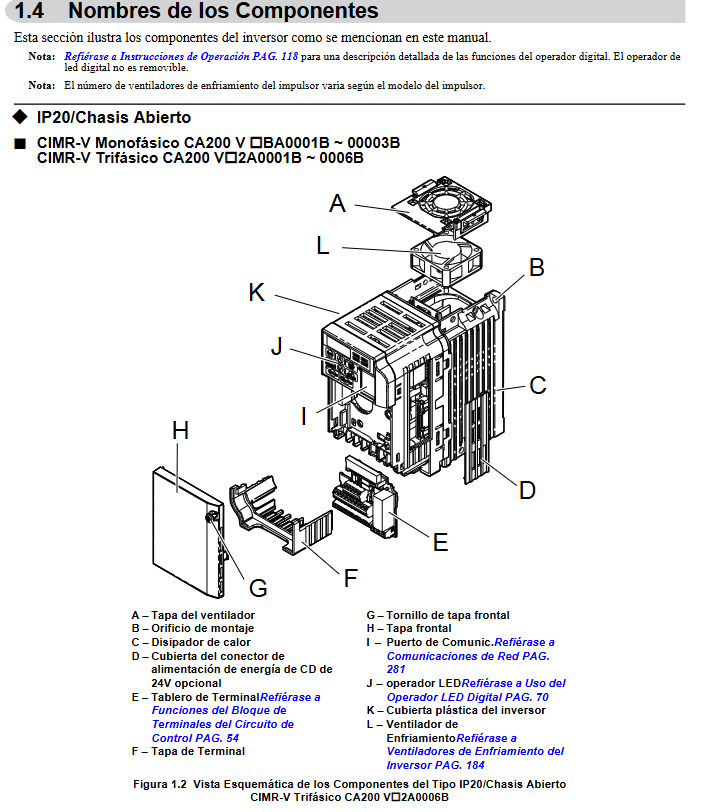

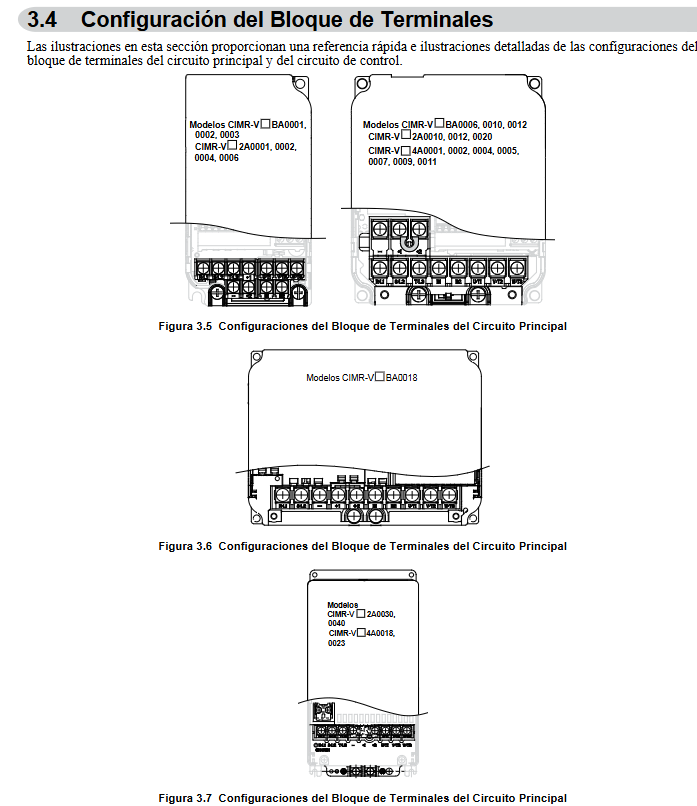

Component Identification

The key components include LED operators, heat sinks, terminal blocks, cooling fans, communication ports, etc. The layout of components with different protection types and power levels varies, and needs to be confirmed by referring to the manual illustrations.

Mechanical Installation

Installation environment requirements

Environmental conditions: Indoor installation, temperature range IP20 open type (-10~50 ℃), IP20/NEMA1 type (-10~40 ℃), humidity ≤ 95%, no condensation, altitude ≤ 1000m, no dust, oil pollution, strong vibration (10-20Hz ≤ 9.8m/s ², 20-55Hz ≤ 5.9m/s ²).

Taboo environment: Avoid direct sunlight, corrosive gases, radioactive substances, and installation near flammable materials.

Installation specifications

Installation direction: It must be installed vertically to ensure heat dissipation effect, and horizontal or inclined installation is prohibited.

Spacing requirements: The vertical spacing of a single device should be ≥ 100mm, and the horizontal spacing should be ≥ 30mm; when multiple devices are installed side by side, the adjacent spacing should be ≥ 2mm, and the rated power should be reduced and the parameter L8-35 adjusted.

Size and fixing: The external dimensions and installation holes of different models of frequency converters vary, and the appropriate installation method should be selected according to the manual table. The fixing torque should meet the requirements (such as 0.5-0.6N · m for M3 bolts).

Electrical Installation

Wiring Safety and Standards

Wiring prerequisite: Power off and wait for the capacitor to discharge completely, wear insulation protective equipment to avoid cable cross interference.

Main circuit wiring: Use 600V ethylene insulated cables, and connect the main circuit terminals (R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, etc.) according to the diagram. The grounding requirements are 200V level ≤ 100 Ω and 400V level ≤ 10 Ω.

Control circuit wiring: Use shielded twisted pair cables to avoid parallel connection with the main circuit cables, and the shielding layer needs to be grounded; The control circuit terminals include digital input/output, analog input/output, communication terminals, etc., which need to be wired according to functional configuration.

Key Wiring Details

Braking resistor connection: can only be connected to B1/B2 terminals, and needs to be protected by a thermal relay to avoid overload and burnout.

Communication wiring: Supports MEMOBU/Modbus communication, requires the use of RS-485/422 cables, and the terminal resistance is controlled through DIP switch S2 (the end device needs to be turned on).

Cable specifications: Select the appropriate cable cross-sectional area based on the frequency converter model (such as 2mm ² recommended for the main circuit cable of the 200V single-phase 0.1kW model). After wiring, tighten the terminals with the required torque (such as 0.8-1.0N · m for M3.5 bolts).

Programming and Startup Operations

Use of LED Operators

Operator functions: including data display area, ESC key, RESET key, RUN key, up and down arrow keys, STOP key, ENTER key, LO/RE switch key, which can realize mode switching, parameter editing, operation monitoring, fault reset and other operations.

Display and indicator lights: RUN indicator light displays the running status, LO/RE indicator light displays the local/remote mode, ALM indicator light displays the fault status, and frequency, current, parameter and other information can be viewed through the digital display area.

Core Programming Settings

Control mode selection: Set through parameter A1-02, supporting V/f control (0), open-loop vector control (2), and open-loop vector control of permanent magnet synchronous motor (5).

Application preset parameters: Select 7 types of application presets (pumps, conveyors, etc.) through parameter A1-06, automatically configure the optimal parameters, and simplify debugging.

Basic parameter configuration: including acceleration/deceleration time (C1-01~C1-11), carrier frequency (C6-02, 2-15kHz optional), motor parameters (E2-01~E2-12, configurable through automatic adjustment function), frequency command source (b1-01), etc.

Start up process

Initialization settings: Select control mode and application presets based on the application scenario, and initialize parameters (A1-03).

Auto Ajuste: divided into rotary type (motor rotation, adapted to open-loop vector control) and stationary type (motor non rotation, adapted to V/f control), used for automatically configuring motor parameters to ensure control accuracy.

Trial operation: No load test (to confirm motor steering, acceleration/deceleration stability) → Load test (to verify operating status and parameter effectiveness) → Jogging operation (FJOG/RJOG function, 6Hz low-speed test).

Troubleshooting

Fault classification and warning

Fault types: including hardware faults such as overcurrent (oC), overvoltage (ov), overload (oL1/oL2), overheating (oH), operational errors such as communication errors (CE), parameter errors (oPE), and adjustment errors during the Auto Ajuste process.

Warning method: When a fault occurs, the LED operator displays a fault code and the ALM indicator light remains on; The ALM indicator light flashes when there is a minor malfunction or alarm.

Common troubleshooting solutions

Overvoltage (ov): Extend deceleration time (C1-02, etc.), install braking resistors, enable overvoltage suppression function (L3-11=1), check input voltage spikes.

Overcurrent (oC): Check motor insulation and wiring, reduce load, extend acceleration time, lower carrier frequency, confirm motor type matches control mode.

Overload (oL1): Reduce load, extend acceleration/deceleration time, check motor rated current configuration (E2-01), confirm motor cooling system is normal.

Parameter Error (oPE): Verify the parameter configuration logic (such as matching carrier frequency and cable length), restore default parameters, and reconfigure.

Fault reset method

Manual reset: Reset by pressing the RESET button on the operator.

Automatic reset: Configure parameter L5-01 to set the number of automatic retries.

Power off reset: Disconnect the power supply for ≥ 5 minutes and then power it back on (applicable to serious faults).

Regular Maintenance and Overhaul

Maintenance cycle and projects

Daily inspection: clean appearance, running sound, heat dissipation, terminal fastening status.

Regular inspection: Check cable aging, cooling fan operation status, capacitor and IGBT status every 6 months to 1 year (monitored through U4-05/U4-07).

Maintenance cycle: When the service life of the cooling fan expires (U4-04 ≥ 90%), it needs to be replaced in a timely manner; Replace capacitors and IGBTs when they reach the maintenance threshold.

Maintenance of key components

Cooling fan: Regularly clean the dust on the fan blades, replace them when damaged or aged, and reset the parameter o4-03=0 after replacement.

Terminals and cables: Check the tightness of the wiring to avoid looseness and overheating; Replace aging cables in a timely manner to ensure insulation performance.

Inverter replacement: During replacement, parameter configuration can be transferred through a detachable terminal block to reduce the workload of reprogramming.

Peripheral Devices and Options

Peripheral Device Adaptation

Protective equipment: Molded Case Circuit Breakers (MCCBs), Residual Current Circuit Breakers, Thermal Relays (OL), etc. must be installed to comply with local electrical regulations.

Filtering and reactors: Input filters, EMC filters, and AC/DC reactors can be installed to reduce electromagnetic interference and improve input current waveforms.

Communication Options

Supports MEMOBU/Modbus communication protocols and can be adapted to more bus protocols by extending the communication card. Wiring must follow communication specifications and configure corresponding parameters (such as baud rate and address).

Technical Specifications and Parameter List

Core specifications

Output characteristics: Voltage range 0- input voltage, frequency range 0-400Hz, overload capacity of normal working mode 120%/60s, overload mode 150%/60s.

Protection function: including multiple protections such as overcurrent, overvoltage, overload, overheating, phase loss, and ground fault.

Parameter List

Parameter grouping: divided into initialization parameters (A), application parameters (b), adjustment parameters (C), motor parameters (E), terminal function parameters (H), protection function parameters (L), monitoring parameters (U), etc., covering all configurable items such as control mode, operating parameters, protection thresholds, etc. Each parameter is labeled with default values, configuration ranges, and functional descriptions.

Key technical points

Motor adaptation

Supports ordinary induction motors and permanent magnet synchronous motors (PM). Permanent magnet synchronous motors require motor code (E5-01) and related parameters (E5-02~E5-24) to be configured, and speed search function (b3-01=1) to be enabled.

Motor parameter configuration: Accurate input of motor rated current, number of poles, rated power, and other information is required, or automatically obtained through the Auto Ajuste function to ensure control accuracy.

Differences in Control Modes

V/f control: Suitable for ordinary speed regulation scenarios (such as fans and pumps), with a simple structure and support for multi motor control.

Open loop vector control: suitable for high-precision speed regulation and high starting torque scenarios (such as conveyors and cranes), requiring Auto Ajuste to optimize parameters.

Permanent magnet synchronous motor control: efficient and energy-saving, suitable for scenarios with variable torque and high energy efficiency requirements, requiring dedicated parameter configuration.

Core taboos for safe operation

Prohibited items: live wiring/plugging of components, use of single-phase motors, covering of heat dissipation ports, modification of internal circuits of frequency converters, use of mismatched voltage power supplies.

Required items: reliable grounding, operation after power outage and discharge, operation by qualified personnel, tightening terminals according to specifications, regular maintenance of cooling system.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923