K-WANG

YASKAWA GA500 series AC micro frequency converter

Model identification: CIPR-GA50Cxxxxxxxx, core specifications are classified as follows:

Voltage level, input type, power range, key parameters

200V single-phase 0.1-4.0 kW Max

200V C three-phase 0.1-22kW speed control range 1:40~1:100

400V level three-phase 0.37-30 kW protection level IP20/UL open type

Core features: Supports 5 control modes, compatible with induction motors, PM motors (including IPM/SPM), and synchronous reluctance motors (SynRM), with functions such as automatic tuning, energy saving, and dynamic braking.

YASKAWA GA500 series AC micro frequency converter

Product basic information

1. Product positioning and specifications

Product Name: YASKAWA GA500 Series AC Micro Drives for Industrial Applications

Model identification: CIPR-GA50Cxxxxxxxx, core specifications are classified as follows:

Voltage level, input type, power range, key parameters

200V single-phase 0.1-4.0 kW Max

200V C three-phase 0.1-22kW speed control range 1:40~1:100

400V level three-phase 0.37-30 kW protection level IP20/UL open type

Core features: Supports 5 control modes, compatible with induction motors, PM motors (including IPM/SPM), and synchronous reluctance motors (SynRM), with functions such as automatic tuning, energy saving, and dynamic braking.

2. Definition of core terms

Key abbreviations: OLV (open-loop vector control), PM (permanent magnet synchronous motor), MFAI (multifunctional analog input), MFDO (multifunctional digital output), ND (normal load), HD (heavy load)

Safety Signs: DANGER (Fatal Danger), Warning (Serious Danger), CAUTION (Minor Injury), NOTICE (Equipment Damage)

Installation specifications

1. Mechanical installation requirements

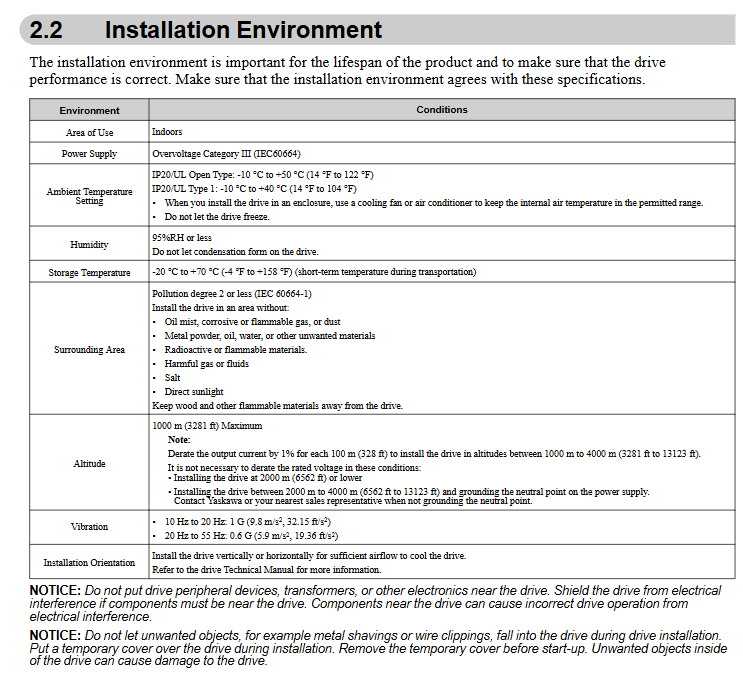

Environmental conditions: Indoor use, pollution level 2, altitude ≤ 1000m (with a 1% reduction in capacity for every 100m exceeding 1000m), vibration ≤ 1G (10-20Hz)/0.6G (20-55Hz)

Installation gap: Single driver up and down ≥ 100mm, left and right ≥ 30mm; for parallel installation, L8-35=1 should be set, and for horizontal installation, some models require an external cooling fan (such as B001-B012, which requires a 0.18m ³/min air flow fan)

Disassembly and assembly operation: The front cover/keyboard requires a specified size screwdriver (blade width ≤ 2.5mm) to avoid touching the internal capacitors (after power failure, wait for voltage ≤ 50Vdc)

2. Electrical installation specifications

Main circuit wiring:

Terminal functions: R/L1/S/L2/T/L3 (input), U/T1/V/T2/W/T3 (motor output), B1/B2 (braking resistor), grounding terminal (200V class ≤ 100 Ω, 400V class ≤ 10 Ω)

Wire specifications: Recommended 2.5mm ² for 200V single-phase B001 model, 25mm ² for 400V three-phase 4060 model, tightening torque 0.5-5.5N · m (depending on terminal size)

Control circuit wiring:

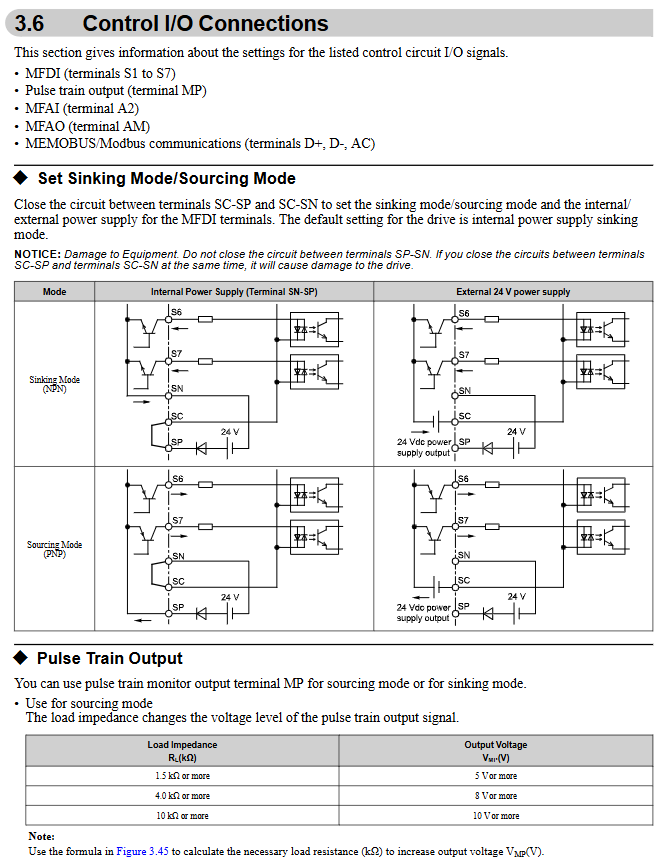

Signal mode: MFDI supports Sink/Source mode, switched through SC-SP/SC-SN jumper

Wiring requirements: Shielded twisted pair, length ≤ 50m, distance from main circuit ≥ 30cm, to avoid electromagnetic interference

Startup and Debugging Process

1. Operation preparation

Parameter settings:

General setting mode (SrUP): including 26 core parameters such as control mode (A1-02), acceleration and deceleration time (C1-01/C1-02), motor parameters (E2-01~E2-04), etc

Application preset (A1-06): Automatically optimize parameters for specific scenarios, requiring initialization (A1-03=2220/3330)

Keyboard operation: Supports LOCAL/EMOTE switching, RUN/STOP keys (STOP key priority can be disabled through o2-02), can backup/restore parameters (o3-01)

2. Auto Tuning

Tuning type:

Applicable scenarios for motor type tuning method parameter settings

Induction motor rotation tuning T1-01=0. The motor can disconnect from the load and requires a no-load rate of ≥ 30%

Induction motor static tuning T1-01=1 motor cannot rotate, load ≤ 30%

PM motor rotation tuning T2-01=4 needs to disconnect the load and automatically detect motor parameters

PM motor static tuning T2-01=1 motor fixed, suitable for non rotating scenarios

Prerequisite: Enter the motor nameplate parameters (rated power, voltage, current, number of poles), disable safe disable input during tuning, and avoid personnel approaching rotating parts.

3. Test Run

No load test: Start at a frequency of 6Hz, gradually increase to the rated frequency, and check the motor direction, vibration, and current (≤ rated current)

Load testing: Verify acceleration/deceleration response and torque output, fine tune parameters through C4-01 (torque compensation) and n1-02 (anti oscillation gain)

Checklist: Confirm power supply voltage, wiring correctness, protection parameters (L1-01 motor overload protection), and control signal effectiveness

Standard Compliance and Safety

1. Main compliance standards

EU CE: Complies with LVD (2014/35/EU), EMC (2014/30/EU), Machinery Directive (2006/42/EC), requires the use of built-in EMC filters (model suffix E) and proper grounding

UL in the United States and Canada: Compliant with UL 61800-5-1, branch circuit protection requires designated fuses (such as FWH-25A14F for B001), and control circuits require UL certified Class 2 power supply

China RoHS: Restricting harmful substances such as lead and mercury, providing a list of hazardous substances

2. Core safety requirements

Electrical safety: Wait for at least 5 minutes after power failure, prohibit live wiring/cover removal, grounding wire cross-section ≥ 10mm ² (copper core)

Mechanical safety: It is prohibited to grip the keyboard/front cover during lifting, the installation area should be free of flammable materials, and the emergency stop circuit should be independent of the frequency converter

Functional safety: Safe Disable input (H1/H2/HC) requires Source mode, with a wiring length of ≤ 30m

Operation and maintenance

1. Network communication

Supporting protocol: MEMOBU/Modbus (RS-485), with a maximum baud rate of 115.2kbps, supports master-slave configuration, and can communicate with PLC

Communication settings: The terminal resistor is enabled through DIP switch S2, and the last slave needs to be set to ON. The message format includes address, function code, and data segment

2. Troubleshooting

Common faults: OV (overvoltage), oL1 (motor overload), STPo (motor out of step), oC (overcurrent)

Troubleshooting process: After the fault occurs, power off for cooling, check the wiring → parameter settings → load status → motor insulation, and monitor the operating data (output frequency/current/voltage) through U1 xx

3. Maintenance and disposal

Regular inspection: daily (operation status, abnormal noise), regular (cooling fan replacement, 2-5 years according to model), storage (-20~70 ℃, moisture-proof)

Scrap requirements: Follow the WEEE directive, classify and dispose of electronic components and metal casings, and prohibit the indiscriminate disposal of oil/hazardous substance containing components

Summary of Key Parameters

Parameter Category Core Parameters Default Values Adjustment Range Usage

Control mode A1-02 0 (V/f) 0-8 Select control mode (V/f/OLV/PM, etc.)

Motor protection L1-01 according to A1-02 0-6 motor overload protection type (constant torque/variable torque)

Acceleration and deceleration time C1-01/C1-02 1.0 0.01-3600 years adjustment start/stop smoothness

Carrier frequency C6-02 1 (2kHz) 1- Upper limit balanced motor noise and heat dissipation

Braking resistor L8-01 0 (disabled) 0-1 enables ERF type braking resistor protection

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923