K-WANG

Allen Bradley 1391-DES series digital AC servo drive

Allen Bradley 1391-DES series digital AC servo drive

Basic information of the driver

Product positioning and functionality

1391-DES is a digital programmable single axis AC servo drive that is compatible with Allen Bradley 1326 series AC servo motors. It is mainly used in closed-loop positioning systems such as machine tools and automation equipment (such as IMC S-class and MAX controllers), and supports speed and torque control modes.

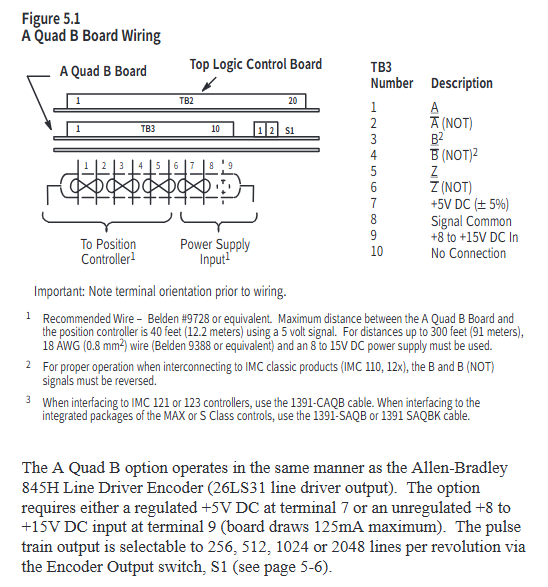

Core advantage: It can enable the 1326 motor to exceed the rated speed by 33% -50%, improving equipment accuracy and production efficiency; Equipped with encoder output (AQB), providing position feedback signals of 256/512/1024/2048 lines per revolution, compatible with positioning controllers.

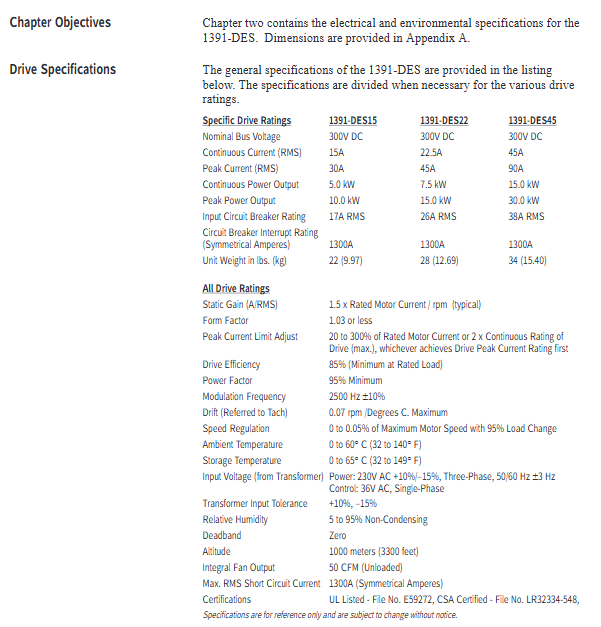

Model and Key Parameters

Model classification: Divided by continuous current, it is 1391-DES15 (15A), 1391-DES22 (22.5A), and 1391-DES45 (45A), all of which have the same physical dimensions but different electrical parameters.

Core electrical parameters: rated DC bus voltage of 300V DC, peak current twice the continuous current (such as DES45 peak 90A), modulation frequency of 2500Hz ± 10%, speed regulation accuracy of 0-0.05% (under 95% load variation), operating temperature of 0-60 ° C, no need to reduce capacity at altitude ≤ 1000 meters.

Standard configuration and optional features

Standard functions: Input transient voltage protection, built-in circuit breaker, DC bus shunt regulator (dissipating regenerative energy), 2-row LCD display and programming panel, torque feedforward differential input, microprocessor control board (easy to disassemble and troubleshoot).

Optional functions: Contactor auxiliary switch (for motor braking control or status indication), external shunt resistor (suitable for high regenerative energy scenarios, such as optional 386W external resistor for 22.5A drivers), speed/current monitoring output, anti backlash control, linear acceleration/deceleration module (CR-APG-001, supports 4 preset speeds).

Working principle

Core Circuit and Energy Processing

Power Conversion: Convert 3-phase 50/60Hz AC power into 300V DC bus voltage through a rectifier bridge, and then output variable voltage AC power through a PWM inverter to control motor speed and torque.

Regenerative braking: The regenerative energy generated during motor deceleration will increase the DC bus voltage. When the shunt regulator detects that the voltage exceeds the threshold (386.4V DC), it triggers the chopper transistor to conduct, converting the energy into thermal energy through the braking resistor to avoid bus overvoltage tripping (overvoltage protection threshold 405V DC).

control logic

Closed loop control: By using a motor resolver (rotary transformer) to provide feedback on the rotor position, combined with speed/torque commands, and adjusting through current and speed loops, precise control is achieved; The current loop adopts analog control, and the speed command supports ± 10V DC analog input.

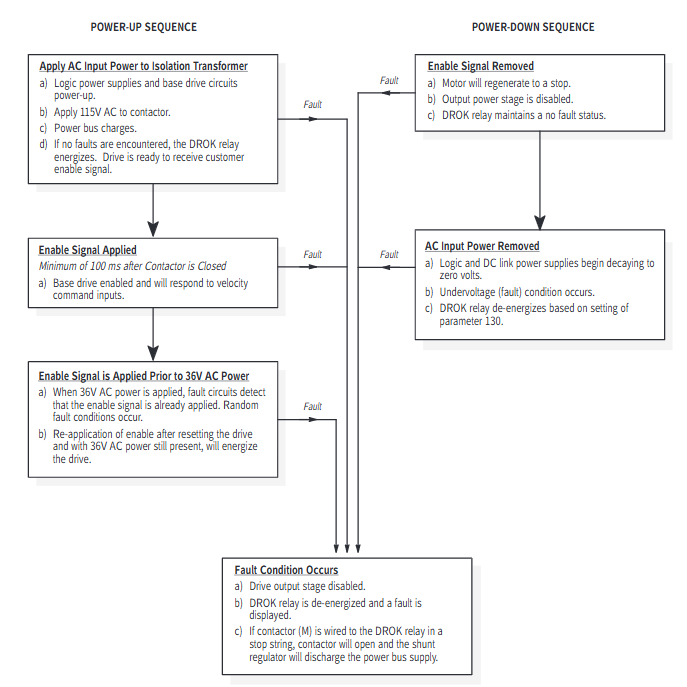

Start stop mode: includes three modes: dynamic braking (bus discharge braking when the contactor is disconnected), regenerative braking (reverse torque braking when the enable signal is disconnected), and free parking (driver disconnection output in case of fault, motor inertia parking).

Installation and wiring

Installation requirements

Environment: It needs to be installed in a closed cabinet, and ventilation should be filtered/cooled to avoid oil mist, dust, and corrosive gases; Vertical installation, distance between single driver and motor ≤ 3m, distance between main driver and frequency converter ≤ 3m when multiple drivers, distance between sub drivers and main drivers ≤ 1.5m, equipment spacing ≥ 304.8mm (to ensure heat dissipation).

Grounding: The driver housing needs to be reliably grounded, and signal grounding (such as resolver, control signal) should use a "star grounding" to avoid introducing noise into the grounding loop.

Wiring specifications

Power wiring: The motor power lines (TB5-1~3) and input power lines (TB5-4~6) need to be twisted pair, separately threaded through pipes, and the wire diameter should refer to the manual (such as 8AWG/6mm ² for DES45); The external shunt resistors (TB5-8~10) need to be matched according to the model (for example, a 45A driver requires an external 5 Ω resistor).

Signal wiring: Control signals such as speed command (TB2-1~2), enable signal (TB2-9~10), reset signal (TB2-11), etc. require 18AWG twisted pair cable with a distance of ≥ 304.8mm from the power line; resolver wiring (TB1-1~10) requires shielded wire with the shielding layer grounded at one end.

Switch and jumper settings

Split regulator duty cycle switch (SW1): adjusts the overheat protection threshold of the braking resistor, and different drivers correspond to different gears (such as setting it to "F" gear when DES22 is equipped with an external resistor).

AQB encoder output switch (S1): Select the number of output lines (256/512/1024/2048), which should match the parameters of the positioning controller (such as halving the number of lines for IMC classic controllers).

Programming and Debugging

Parameter hierarchy and operation

The parameters are divided into three levels: View level (only viewing the operating status, such as speed and current), Modify level (configuring system parameters, such as speed limit and current loop gain), and Maintenance level (advanced parameters, such as inertia compensation and friction compensation), which need to be unlocked through specific key combinations (such as simultaneously pressing the up/down/left arrow+Enter key for Maintenance level).

Core parameters: simulated speed gain (parameter 211, default 500rpm/V, can be calculated based on "maximum motor speed/maximum command voltage"), speed limit (parameters 144/145, default 10% higher than motor rated speed), current limit (parameters 156/157, default 300% motor rated current).

Start debugging process

Preliminary inspection: After confirming that the wiring is correct, power on to verify that the control voltage (± 12V DC,+5V DC) and bus voltage (300V DC) are normal and there are no fault alarms.

Guided start: When powered on for the first time, the driver automatically guides the motor model selection, rotation test (verify motor wiring, rotate clockwise/counterclockwise for 5 seconds each), and zero speed offset calibration (automatically eliminate command offset).

Auto Tune: Starting with parameter 190, the driver automatically measures the system inertia and friction coefficient, calculates the optimal speed loop gain (Kp/Ki), and is suitable for most scenarios; Manual tuning requires adjusting parameters 168 (proportional gain) and 169 (integral gain) to control the speed response overshoot within 20% -30%.

Troubleshooting and Maintenance

fault diagnosis

Fault indication: Front LED light (STATUS light flashing red=fault, green constant light=normal; ENABLE light on=driver enabled), LCD displays specific fault codes (such as "amp overttemp"=driver overheating, "resolver loss"=rotary transformer fault).

Common troubleshooting:

Overvoltage fault: Check whether the input voltage and shunt resistor are open circuited/selected incorrectly, and whether the load inertia is too large;

Rotating transformer fault: Check if the resolver wiring is loose/reversed, and if the cable length exceeds 600 feet;

Overcurrent fault: Check if the motor is short circuited, if the current limit parameter is set too low, and if the load is stuck.

Maintenance points

Regular inspection: clean the cooling fan, confirm that the wiring terminals are not loose, and that the braking resistor has no signs of overheating;

Component replacement: The fuse should be replaced according to the manual model (such as Bussmann KLM10 10A/500V for DES15), avoiding using alternative models; When replacing the control board, pay attention to ESD protection (wear an anti-static wristband).

Supporting equipment and accessories

Adaptation components

Motor: 1326AB series AC servo motor (including Torque Plus series), which needs to be matched with driver current (such as DES22 compatible with 1326AB-B3E motor);

Transformer: 1391 isolation transformer (output 230V AC 3-phase+36V AC 1-phase, such as 1391-T050DT 5kVA model), to ensure UL certification validity;

Cable: 1326 CFUxx (resolver line), 1326 CPABxx (motor power line), 1391-CAQB (AQB encoder line) and other specialized shielded cables.

attachment options

Brake power rectifier (1326-MOD-BPS): provides 115V AC input rectification for 90V DC brake;

Planetary gearbox (1326AB-PG series): compatible with different reduction ratios (3:1-100:1), low backlash option (LB) suitable for high-precision scenarios;

Linear Acceleration and Deceleration Module (CR-APG-001): Manually set trapezoidal speed curve, supporting 4 preset speeds.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923