K-WANG

Schneider Electric 140CHS 1100 Communication Module

Schneider Electric 140CHS 1100 Communication Module

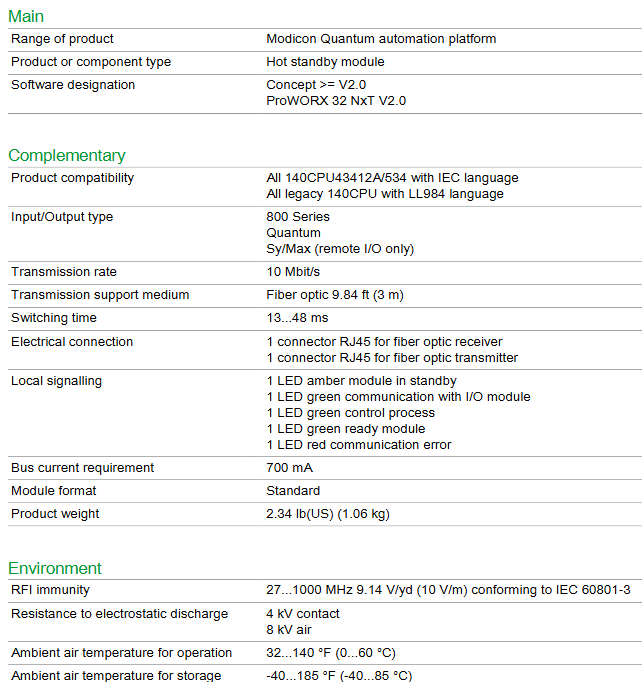

140CHS 1100 is the core communication module of Schneider Electric's Modicon Quantum series PLC, mainly used to connect Quantum controllers with industrial Ethernet networks. It supports mainstream industrial communication protocols such as Modbus TCP/IP, has high stability, flexible expansion, and redundant communication capabilities, and is suitable for the needs of equipment networking, data exchange, and remote monitoring in industrial automation, process control, and other scenarios. It is a key component in building Ethernet communication architecture for Quantum systems.

Basic Information and Product Positioning

1. Core identification and ownership

Product model: 140CHS 1100 (unique ordering and hardware identification code)

Product series: Modicon Quantum (Schneider's high-end PLC product line, aimed at large-scale industrial control scenarios)

Function positioning: Ethernet communication interface module, as the "network gateway" of Quantum controller, realizing the connection between the controller and the upper computer (such as SCADA system HMI)、 Ethernet data exchange for other PLCs or industrial equipment.

Substitution and Compatibility: There is no direct substitute model, compatible with the full range of Modicon Quantum controllers (such as 140CPU65150, 140CPU67160), and supports collaboration with other modules in the Quantum series (such as I/O modules, specialized functional modules).

2. Core values

Protocol standardization: Native support for Modbus TCP/IP protocol, compatible with industrial Ethernet universal standards, no additional protocol conversion required, reducing system integration complexity.

Communication stability: Adopting industrial grade hardware design, it can withstand electromagnetic interference and environmental fluctuations in industrial sites, ensuring long-term continuous communication without interruption.

Redundancy Support: Supports dual module redundancy configuration (in conjunction with Quantum system redundancy function), automatically switches in case of failure, improves communication link reliability, and is suitable for critical control scenarios such as petrochemicals and power dispatch.

Hardware specifications and electrical characteristics

1. Physical and interface specifications

Size and Installation:

Dimensions: Complies with the Quantum series standard module dimensions (height 130mm x width 36mm x depth 110mm, specific subject to physical object), adopts rail installation, compatible with Quantum standard rack (such as 140XTS00200 rack), occupies one module slot.

Weight: Approximately 0.3kg (excluding accessories), lightweight design does not increase rack load.

Communication interface:

Ethernet port: 1 RJ45 interface, supports 10/100Mbps adaptive speed, compatible with full duplex/half duplex modes, supports Auto MDI/MDI-X automatic line sequence adjustment (no need to distinguish between crossover and straight through lines), convenient for on-site wiring.

Status indicator lights: 2 LED indicator lights (Link/Activity light: green, constantly on indicates link connectivity, flashing indicates data transmission; Fault light: red, constantly on indicates module failure, off indicates normal), visually judging the communication and module status.

2. Electrical parameters

Power supply demand:

Power input: Powered from the Quantum rack backplane, supports DC 5V (typical current 1.2A, maximum current 1.5A), does not require external independent power supply, simplifies wiring.

Power consumption: Typical power consumption is 6W, maximum power consumption is 7.5W, low-power design reduces the overall power load of the rack.

Electromagnetic compatibility (EMC):

Compliant with EN 61000-6-2 (industrial environment immunity) and EN 61000-6-4 (industrial environment emission) standards, it can withstand electrostatic discharge (ESD) ± 8kV (contact discharge) and ± 15kV (air discharge), and has a radio frequency radiation immunity of 10V/m (80-1000MHz), suitable for strong industrial interference environments.

Environmental adaptability:

Working temperature: 0 ° C~60 ° C (non condensing), storage temperature: -40 ° C~85 ° C, suitable for high and low temperature fluctuations in industrial sites.

Humidity: 5%~95% relative humidity (no condensation), resistant to humid environments, no additional moisture-proof measures required.

Communication functions and protocol characteristics

1. Core communication protocol

Modbus TCP/IP:

Role support: Can serve as a Modbus TCP server or client. In server mode, it supports up to 32 concurrent client connections (such as 32 HMIs accessing simultaneously). In client mode, it can actively access other Modbus TCP servers (such as reading remote PLC data).

Data Interaction: Supports Modbus standard function codes (such as 03H read hold register, 06H write single register, 10H write multiple registers), with a maximum data length of 125 registers (16 bits per register), meeting the requirements of batch data transmission in industrial control.

Communication efficiency: At a speed of 100Mbps, the response time of a single Modbus command is ≤ 10ms (within the local area network), ensuring real-time control requirements (such as millisecond level data acquisition and command issuance).

2. Network and scalability

Network configuration:

Support static IP address configuration (set through Quantum programming software Unity Pro), or automatically obtain IP addresses through DHCP, adapting to different network management modes.

Support subnet mask and gateway settings, enable cross network communication (such as connecting enterprise level LAN and on-site control network), and meet the multi area networking needs of large factories.

Extended features:

Support "Peer to Peer" communication between Quantum controllers through Ethernet, without the need for a host computer to transfer data and directly exchange data (such as collaborative control of multiple controllers in a production line).

Compatible with Schneider SoMachine/Unity Pro programming software, module parameter configuration, communication diagnosis, and firmware upgrade can be achieved through software, simplifying operation and maintenance.

Configuration and Operations

1. Configuration tools and processes

Core tools: Schneider Unity Pro programming software (V11 and above, compatible with Windows 10/11 system) or SoMachine software (suitable for later system upgrades) is required.

Configuration steps:

Hardware configuration: Add Quantum controller and 140CHS 1100 module to the software, and specify the slot position of the module in the rack.

Network parameter settings: Configure module IP address, subnet mask, gateway, select Modbus TCP role (Server/Client), and set the upper limit of server connections.

Data Mapping: Map the internal registers of the controller (such as the% MW hold register) to Modbus TCP register addresses, clarifying the correspondence between the data accessed by the upper computer.

Download and Activation: Download the configuration file to the Quantum controller, and the module will automatically load the configuration and start communication. Confirm the status through the LED indicator light.

2. Diagnosis and maintenance

Fault diagnosis:

Software diagnosis: Through the "diagnosis" function of Unity Pro software, view module communication logs (such as connection establishment/disconnection records, instruction timeout records), error codes (such as IP address conflict codes, communication timeout codes), and quickly locate the cause of the fault.

Hardware diagnosis: When the Fault light is constantly on, the module fault information (such as power failure, port failure) can be read through the rack backplane diagnostic interface, or the module can be replaced for testing (compatible with hot plugging, "hot plugging enable" needs to be set in Unity Pro).

Firmware upgrade: Supports online firmware upgrade via Ethernet (requires downloading the latest firmware file from Schneider's official website), without affecting the normal operation of the controller during the upgrade process (ensuring network stability during the upgrade process), improving module functionality and compatibility.

Application scenarios and compatibility

1. Typical application scenarios

Industrial automation production line: As the Ethernet interface of Quantum controller, it connects to HMI (such as Schneider Magelis HMI) to achieve production line status monitoring and parameter setting, and also connects to SCADA system (such as Schneider Citect SCADA) to achieve data acquisition and scheduling throughout the plant.

In the field of process control, in scenarios such as petrochemicals and water treatment, achieve Ethernet communication between Quantum controllers and remote I/O modules (such as Schneider EcoStruxure Control Expert compatible modules), intelligent instruments (such as flow meters and level gauges), and transmit process data and control commands.

Redundant communication architecture: In key scenarios such as power and metallurgy, two 140CHS 1100 modules are configured to achieve communication redundancy. When the main module fails, the backup module automatically takes over communication to ensure uninterrupted transmission of control instructions and data.

2. Compatibility Description

Hardware compatibility: Only compatible with Modbus Quantum series racks and controllers, not compatible with other series of PLCs such as Modbus M340, M580, etc. Please confirm the system hardware ownership before selecting.

Software compatibility: Requires Unity Pro V11 or above, or SoMachine V4 or above. Low version software may not support some configuration features (such as DHCP automatic IP acquisition).

Third party device compatibility: Supports communication with third-party devices that comply with the Modbus TCP/IP standard (such as Siemens S7-1200/1500 PLC, Rockwell ControlLogix controller). By configuring Modbus TCP client/server parameters in the third-party device, cross brand data exchange can be achieved.

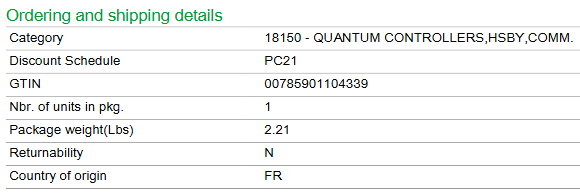

Ordering and spare parts information

1. Order model and accessories

Core module: 140CHS 1100 (standard model, no derivative version, no additional parameters need to be specified when ordering).

Common accessories:

Ethernet cable: CAT5e or CAT6 shielded cable (shielded cable is recommended to reduce interference), the length is selected according to the on-site wiring requirements (maximum transmission distance of 100m).

Module dust cover: Schneider specific dust cover (model to be consulted with the manufacturer), used to protect interfaces and slots when the module is not installed.

Rack: Quantum standard rack (such as 140XTS00200, 2-slot rack; 140XTS00600, 6-slot rack), the number of rack slots should be selected based on the number of modules.

2. Warranty and Support

Warranty period: The original factory standard warranty is 18 months (calculated from the delivery date), and can be extended to 3 years through registration on Schneider's official website (product serial number and purchase certificate are required).

Technical support: Configuration guides and troubleshooting manuals can be obtained through Schneider's global technical support hotline (such as 400-810-1315 in China), the official website's technical documentation center, or by contacting local agents for on-site technical services.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923