K-WANG

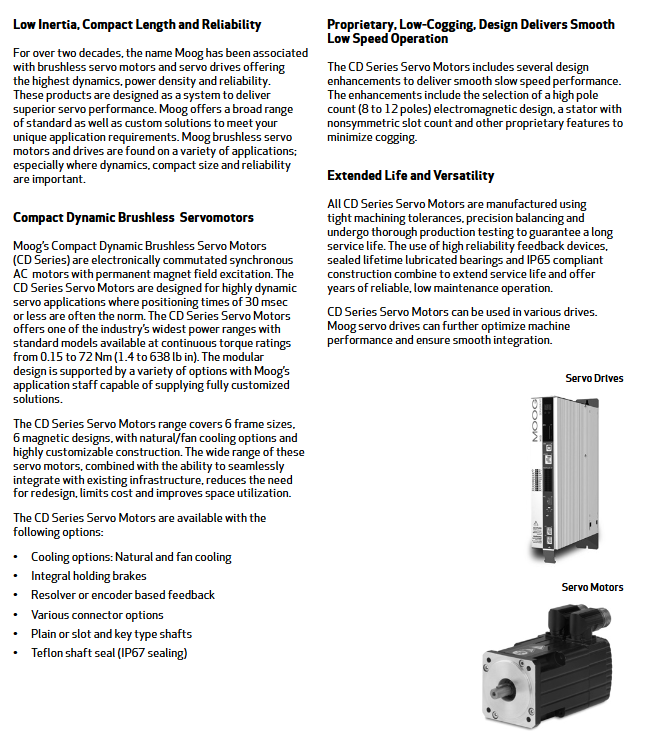

Moog CD series compact dynamic brushless servo motor

Power density optimization: Compact body design (base size 40 mm-190 mm), combined with 8-12 pole electromagnetic structure, achieves high torque output in a small volume (such as the maximum continuous torque of 74.26 Nm for the G-6 model), saving equipment installation space.

Low cogging torque design: By using asymmetric stator slots, high pole layout, and proprietary magnetic circuit optimization, torque fluctuations during low-speed operation are reduced to ensure smooth operation (such as low-speed high-precision transmission for medical equipment and optical detection platforms).

Environmental adaptability: IP65 protection level (shaft seal optional IP67), working temperature -40 ℃~+125 ℃ (short-term reflow soldering withstand 240 ℃/15s), supporting industrial harsh environments such as high dust and humidity; Some models have passed explosion-proof certification and can be used in hazardous areas.

Moog CD series compact dynamic brushless servo motor

Core product positioning and technological advantages

1. Core features and applicable scenarios

High dynamic response: The rotor has a low moment of inertia (minimum 0.027 kg · cm ²), and the positioning time can be as low as within 30 ms, suitable for dynamic scenarios such as high-speed start stop and precision positioning (such as electronic component assembly robots and laser processing equipment).

Power density optimization: Compact body design (base size 40 mm-190 mm), combined with 8-12 pole electromagnetic structure, achieves high torque output in a small volume (such as the maximum continuous torque of 74.26 Nm for the G-6 model), saving equipment installation space.

Low cogging torque design: By using asymmetric stator slots, high pole layout, and proprietary magnetic circuit optimization, torque fluctuations during low-speed operation are reduced to ensure smooth operation (such as low-speed high-precision transmission for medical equipment and optical detection platforms).

Environmental adaptability: IP65 protection level (shaft seal optional IP67), working temperature -40 ℃~+125 ℃ (short-term reflow soldering withstand 240 ℃/15s), supporting industrial harsh environments such as high dust and humidity; Some models have passed explosion-proof certification and can be used in hazardous areas.

2. Key technological advantages

Dual voltage level adaptation: divided into low voltage version (G-X-M, DC 325 V, equipped with NTC temperature sensor) and high voltage version (G-X-V, DC 565 V, equipped with PTC temperature sensor), adapted to different servo drive power supply requirements, balancing low voltage safety and high voltage efficiency.

Flexible feedback options: Supports rotary transformers (Resolvers, 2-pole, strong anti-interference), incremental encoders (such as Heidenhain ERN series), and absolute encoders (single/multi turn, such as Stegmann SKS series) to meet different accuracy requirements from general positioning to precision closed-loop control.

Long life design: using lifetime lubricated sealed bearings, F-class insulated windings (temperature resistance of 155 ℃), coupled with rotor precision dynamic balancing (ISO 1940 G6.3 level), with a long mean time between failures (MTBF) and reduced maintenance costs.

Product series and technical parameters

1. Machine base size and performance range

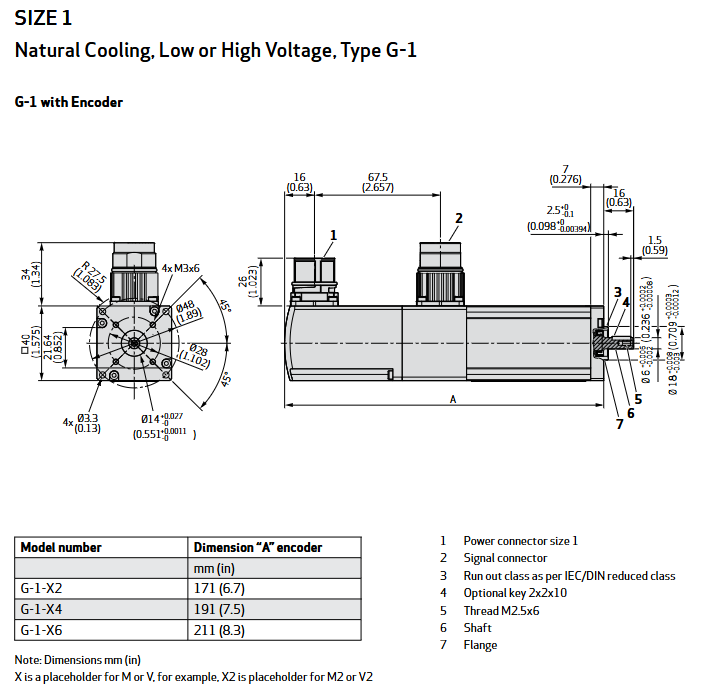

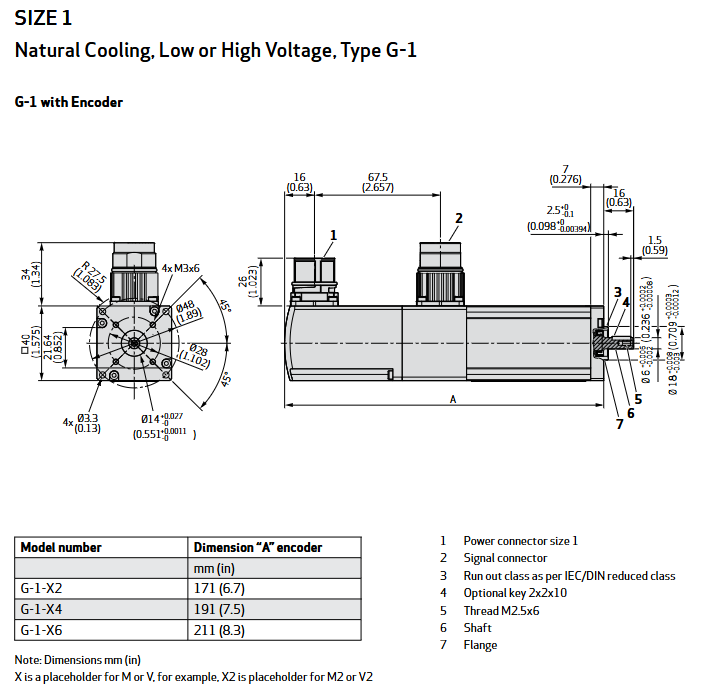

The CD series is divided into 6 models (G-1 to G-6) according to the size of the machine base (flange diameter), and the core parameters of each model cover the following range:

Machine base model, flange size (mm), continuous torque range (Nm), maximum torque range (Nm), rated speed (r/min), rotor moment of inertia (kg · cm ²), weight (kg)

G-1 40 0.16-0.35 0.50-1.51 6000-9000 0.027-0.072 0.55-0.84

G-2 55 0.24-2.02 0.83-6.64 5000-8000 0.070-0.44 1.0-2.3

G-3 70 0.55-3.94 1.72-13.33 3400-11000 0.14-0.97 1.7-3.5

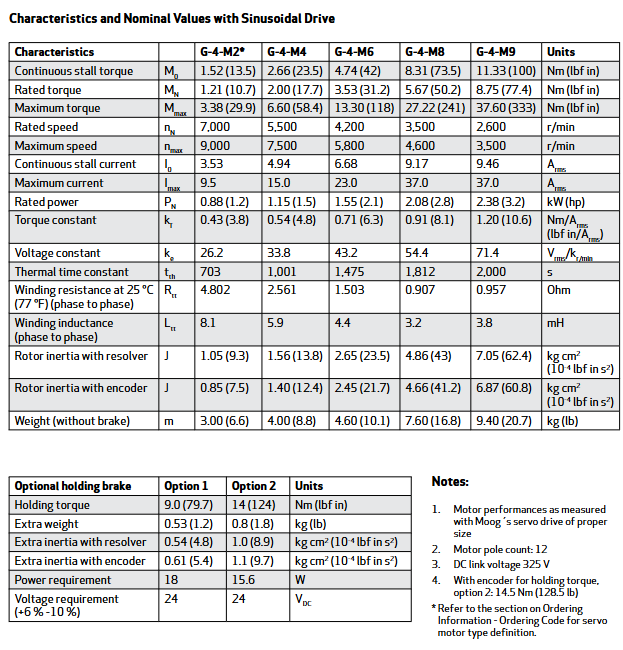

G-4 100 1.25-11.33 3.38-41.40 2600-8000 0.85-7.05 3.0-9.4

G-5 140 5.80-35.17 13.25-94.55 1800-5000 4.51-27.23 7.7-21.0

G-6 190 14.0-74.26 40.25-240.06 2000-4000 27.56-156.98 15.1-44.8

2. Key electrical and mechanical parameters

Electrical performance:

Torque constant (kT): 0.17 Nm/A~2.45 Nm/A (such as G-6-V9 model kT=2.27 Nm/A), high current control accuracy;

Voltage constant (ke): 11.1 Vrms/krpm~145.6 Vrms/krpm, adapted to the back electromotive force requirements at different speeds;

Insulation resistance ≥ 10 ¹² Ω, test voltage 1 kV~3.1 kV (higher for high voltage models), ensuring high voltage safety.

Mechanical properties:

Shaft diameter and keyway: adapted to the size of the machine base (such as G-1 shaft diameter of 6 mm, G-6 shaft diameter of 32 mm), supporting optical axis and keyway shaft (compliant with DIN 6885 standard);

Bearing load: Maximum radial load of 250 N (G-6), maximum axial load of 500 N (G-6), compatible with various transmission modes such as belts and gears;

Cooling methods: natural cooling (standard), forced air cooling (G-4~G-6 optional, increasing continuous torque by 30%).

Flexible configuration and customization options

1. Standard configuration options

The CD series motor supports multi-dimensional standard configurations to meet the needs of different application scenarios:

Braking device: Integrated permanent magnet holding brake (optional 2 torque levels), locks the shaft system after power failure, adapts to vertical axis loads (such as lifting platforms), braking voltage 24 VDC (power 10 W~40 W).

Shaft seal and protection: Standard IP65 (dustproof and waterproof), optional Teflon shaft seal (IP67), suitable for liquid splashing scenarios (such as food processing and cleaning equipment).

Connectors and Wiring: Supports right angle fixing, right angle rotation, and straight connectors, adapting to different installation space wiring requirements; The signal interface distinguishes between power (U/V/W) and feedback (Resolve/Encoder) for easy wiring maintenance.

Temperature monitoring: The low-voltage version is equipped with NTC thermistor (20.489 Ω at 25 ℃), and the high-voltage version is equipped with PTC thermistor (sudden change in resistance at 155 ℃) to monitor the winding temperature in real time and prevent overheating damage.

2. Customization capability

Moog provides deep customization services to meet the needs of special scenarios:

Winding customization: Customize winding parameters based on customer supply voltage (such as non-standard DC 400 V) and speed requirements (such as ultra high speed 15000 r/min), and optimize torque speed characteristics.

Mechanical customization: Customize shaft length, diameter (such as hollow shaft, spline shaft), flange size (such as adapting to customer equipment installation holes), and even frameless (no shell) design, integrated into customer motion mechanisms.

Environmental adaptation: High temperature coating (able to withstand temperatures above 200 ℃), explosion-proof design (ATEX II 3G), radiation resistant version, suitable for extreme environments such as aerospace and nuclear industries.

Feedback customization: Supports multi turn absolute encoders (such as Heidenhain EQN series), Hall sensors, or integrated speed generators to meet high-precision multi turn positioning requirements.

Selection and Application Guide

1. Core dimensions for selection

Load matching: Select the model based on the load inertia (recommended load inertia/motor inertia ≤ 5:1, high dynamic scenario ≤ 1:1), continuous torque, peak torque requirements, and motor torque speed curve (such as the G-4-M8 model with a continuous torque of 8.31 Nm at 3500 r/min).

Voltage and driver adaptation: The low voltage version (325 V) is suitable for small and medium power drivers, while the high voltage version (565 V) is suitable for high-power and high-speed scenarios, ensuring that the DC bus voltage of the driver matches.

Feedback accuracy: For general positioning, choose a Resolver (anti-interference), while for precise positioning, choose an absolute encoder (such as a 13 bit single loop+12 bit multi loop, with a resolution of 4096 × 4096).

Environmental parameters: IP67 shaft seal should be selected for humid/dusty environments, and the temperature resistance level of the winding should be confirmed for high temperature environments. Explosion proof certified models should be selected for hazardous areas.

2. Typical application scenarios

Industrial robots: G-2-G-4 models are used for robot joints, with low inertia supporting fast start stop and high torque density reducing joint volume;

Semiconductor equipment: G-1~G-3 models are used for wafer transfer robotic arms, with low cogging torque to ensure low-speed stability and IP67 protection suitable for clean room environments;

Precision machine tools: G-4~G-6 models are used for spindle or feed axis, combining high torque and high speed to meet high-precision cutting requirements;

Testing and simulation: The G-5~G-6 models are used for aerospace simulators, with high dynamic response and high reliability to support complex motion simulations.

Key points for installation and maintenance

1. Installation specifications

Mechanical installation: The flange needs to be fixed on a steel mounting plate of ≥ 300 × 300 × 25 mm (to ensure heat dissipation), and the axis alignment error should be ≤ 0.1 mm (to avoid excessive radial load);

Electrical connection: Separate the power line (U/V/W) from the signal line (feedback/braking) to avoid electromagnetic interference; The brake power cord needs to be supplied separately to prevent brake failure after the driver is powered off;

Heat dissipation design: Natural cooling motors require a reserved heat dissipation space of ≥ 50 mm, while forced air cooling motors must ensure that the fan inlet is unobstructed (fan voltage 24 VDC, current 1 A).

2. Maintenance suggestions

Regular inspection: Check the bearing noise and shaft seal sealing every 6 months, and shorten it to 3 months in high temperature environments;

Temperature monitoring: Monitor the winding temperature through the driver to avoid exceeding 110 ℃ for a long time (when the ambient temperature is 40 ℃);

Spare parts management: It is recommended to use spare brakes and bearings for key equipment, and Moog provides original factory maintenance services to ensure the shortest downtime.

Order Information

Model coding rules: For example, "G-4-V8" represents G-4 base, high-voltage version (565 V), and 8th stack length (corresponding to continuous torque of 8.31 Nm);

Standard accessories: including motor cables, installation screws, feedback interface manual. Customized models require information on load inertia, speed, environmental parameters, etc.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923