K-WANG

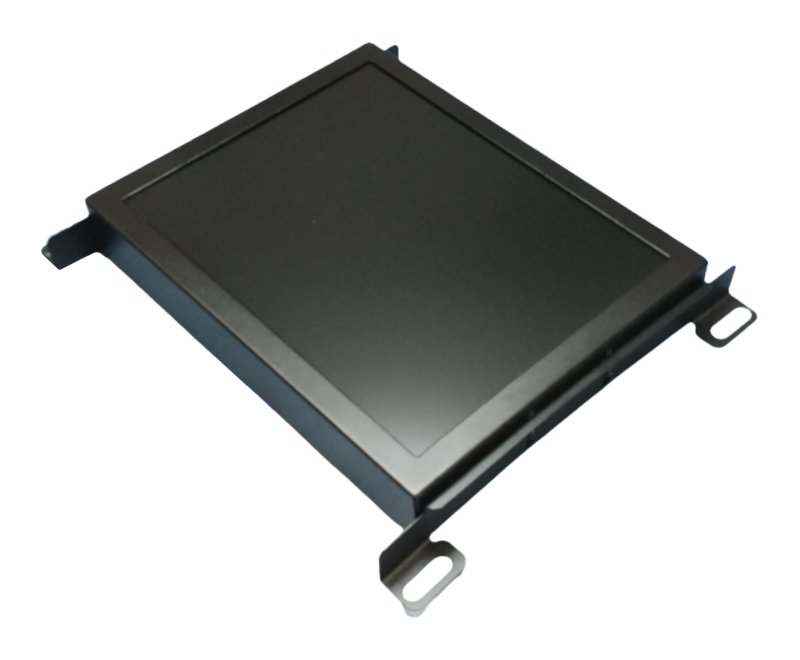

Xycom 2060 LCD Upgrade Monitor with Cable Kit 12 inches

Xycom 2060 LCD Upgrade Monitor with Cable Kit 12 inches

Product Overview

Xycom 2060 12 inch LCD upgraded display with cable kit, designed specifically for industrial automation, equipment monitoring and other fields. By upgrading performance and optimizing interfaces, we solve problems such as low resolution and unstable connections in old display devices. With high-definition display and reliable data transmission, we help visualize and streamline industrial production processes.

Specification parameters

(1) Display parameters

Display performance

Resolution: Increased to 1024 × 768, compared to traditional 12 inch LCD displays, it can present industrial parameter charts, equipment operation interfaces, and other content more clearly, reducing information misjudgment caused by blurry images.

Brightness: reaching 250cd/m ², it can ensure clear and visible screen content in general industrial environments, effectively combating environmental light interference.

Contrast ratio: 800:1, making the brightness and darkness of the screen clear, and the display of equipment operation status indicators, alarm prompts, etc. more prominent, making it easier for operators to quickly identify abnormal situations.

Physical specifications

Size: 12 inch screen, aspect ratio 4:3, compact size suitable for installation in compact industrial control cabinets and operation panels, compatible with existing equipment installation layouts.

Thickness: 15% thinner than previous generation products, further saving installation space, and having a simpler appearance, making it easy to integrate into various industrial equipment.

Weight: reduced by about 10%, convenient for handling and installation, reduces pressure on installation brackets, and enhances equipment stability.

Interface type

New Interface: Equipped with HDMI interface, supporting high-definition digital signal transmission, seamlessly integrating with new industrial computers and intelligent monitoring devices, achieving fast transmission of high-definition images and data.

Retain interface: Retain VGA interface to ensure compatibility with existing industrial equipment, facilitate users' gradual transition during device updates, and avoid resource waste.

(2) Cable kit parameters

HDMI cable

Length: Available in two specifications of 1 meter and 2 meters, the 1-meter cable is suitable for compact installation scenarios of equipment; The 2-meter cable can meet the connection needs of slightly longer distances between devices and adapt to different industrial equipment layouts.

Transmission standard: Compliant with HDMI 1.4 standard, supports 1080p high-definition video transmission, with a data transmission rate of up to 3.4Gbps, ensuring smooth and delay free images, and clearer real-time monitoring of industrial production processes.

Material: Made of high-quality pure copper conductor and multi-layer shielding structure, effectively resisting electromagnetic interference in industrial environments, ensuring stable signal transmission, and avoiding snowflakes and stuttering on the screen.

VGA cable

Length: The standard length is 1.5 meters, suitable for most industrial equipment installation distances, and meets the basic connection requirements between the equipment and the display.

Interface type: DB-15 male head at both ends, using gold plating process, anti-oxidation, anti-corrosion, low contact resistance, ensuring stable and reliable signal transmission, extending cable service life, and reducing display failures caused by interface problems.

Core functions

(1) High definition visualization

High resolution and excellent color performance enable the monitor to clearly display industrial equipment operation data, production process images, and complex engineering drawings. Operators can read information more accurately, timely discover equipment hazards and production abnormalities, and provide reliable basis for decision-making.

(2) Flexible connection adaptation

The cable kit has rich interfaces and diverse length specifications, supporting the connection of displays with different types and locations of industrial equipment. Both new intelligent devices and old devices still in service can achieve stable data transmission, improving device universality and system integration.

(3) Stable signal transmission

The high-quality material and shielding design of the cable, combined with the optimized signal processing module of the display, effectively resist the effects of electromagnetic interference and power fluctuations in industrial environments, ensuring stable and clear images and avoiding production operation errors caused by unstable signals.

Working principle

The monitor receives video and data signals from industrial devices such as computers and PLC controllers through HDMI or VGA interfaces. The digital signal transmitted through HDMI cable is directly received and processed by the digital processing chip of the display, and converted into image display; The analog signal transmitted by VGA cable is first converted into a digital signal by the internal A/D conversion module of the display, and then processed and displayed by the digital processing chip. During the transmission process, the cable shielding layer works in conjunction with the display anti-interference circuit to filter out external interference and ensure signal integrity and accuracy.

Upgrade Operation Guide

(1) Preparation work

Ensure that the equipment is completely powered off to avoid the risk of electric shock or equipment damage during operation.

Prepare installation tools such as Xycom 2060 12 inch LCD upgrade monitor, cable kit, screwdriver, etc.

(2) Disassemble the original monitor

Use a screwdriver to unscrew the screws that secure the original monitor and carefully remove the monitor casing.

Disconnect the cables connecting the original monitor to the device, remember the interface connection location and type, to facilitate the installation of a new monitor in the future.

(3) Install a new monitor

Place the new monitor in its original installation position and secure the housing with screws to ensure a secure installation and prevent the monitor from loosening due to vibration.

Select the appropriate cable (HDMI or VGA) based on the device interface type, connect one end to the corresponding interface of the device and the other end to the monitor interface, ensuring a tight and secure connection.

(4) Testing and Debugging

Connect the device power, turn on the monitor and device, and check if the monitor is displaying the image normally.

If the display is abnormal, check if the cable connection is correct, if the interface is loose, or try replacing the cable for testing.

Enter the monitor settings menu and adjust parameters such as resolution, brightness, contrast, etc. according to actual needs to optimize the display effect.

Precautions

(1) Installation and use

During installation, avoid excessive pulling of cables to prevent internal conductor breakage or interface damage, which may affect signal transmission performance.

Do not use the monitor in harsh environments such as high temperature, humidity, and strong magnetic fields. If it needs to be used in special environments, protective measures should be taken, such as installing protective shells and using shielding devices.

Regularly check the cable connection to avoid cable loosening or detachment caused by vibration, which may affect the normal operation of the equipment.

(2) Maintenance and upkeep

When cleaning the monitor screen, use a specialized cleaning cloth and cleaner, gently wipe it, avoid using rough fabrics or corrosive cleaners, and prevent scratching the screen or damaging the coating.

Regularly remove dust from the monitor, use dry compressed air or soft bristled brushes to clean the dust from the heat dissipation holes, interfaces, and other parts, maintain good heat dissipation and electrical connection performance of the equipment, and prevent overheating or poor interface contact caused by dust accumulation.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- xYCOM

- Construction site

- Siemens

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Motorola

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive