K-WANG

WAGO 221 series LEVER-NUTS ® Compact splicing connector

Core value: Achieving a 40% volume reduction without sacrificing connection performance, while simplifying operation processes and improving installation safety, becoming a "full scene adaptive product" in the field of electrical connections.

Core technology: Continuing and optimizing WAGO's patented lever technology, wire clamping and fixation can be completed without the need for additional tools.

WAGO 221 series LEVER-NUTS ® Compact splicing connector

Product basic information

1. Product positioning

Iterative relationship: The successor to the classic compact splicing connector of the 222 series, with a core upgrade focused on "space optimization+operational convenience+safety visualization".

Core value: Achieving a 40% volume reduction without sacrificing connection performance, while simplifying operation processes and improving installation safety, becoming a "full scene adaptive product" in the field of electrical connections.

Core technology: Continuing and optimizing WAGO's patented lever technology, wire clamping and fixation can be completed without the need for additional tools.

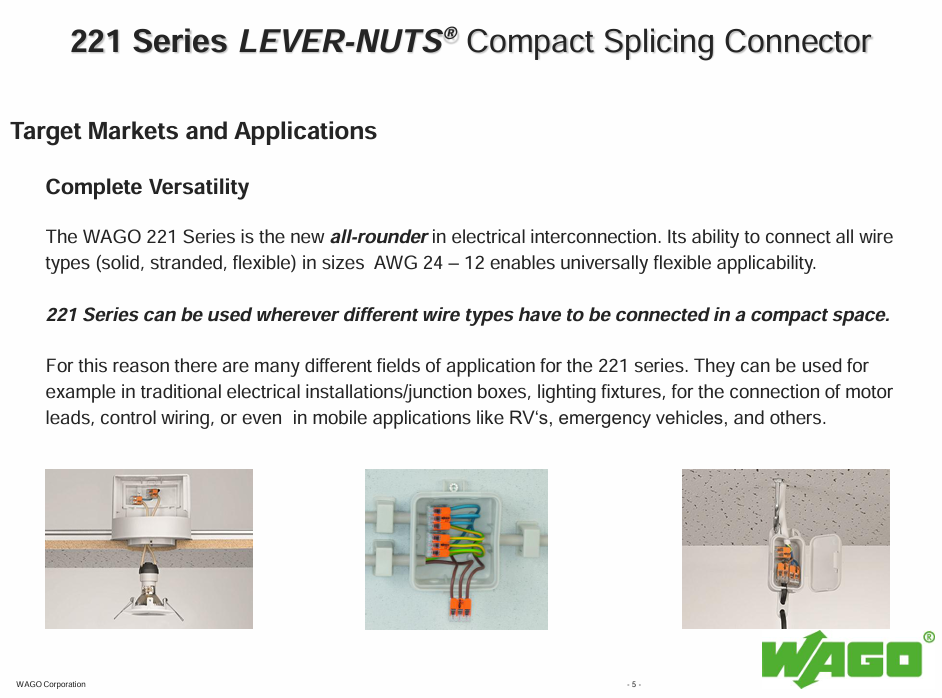

2. Target market and core application scenarios

Applicable fields: covering multiple scenarios such as traditional electrical installation, mobile devices, industrial control, etc. Core applications include:

Building electrical: wiring of junction boxes, wiring of lighting fixtures, connection of wall switches and socket circuits;

Industrial control: motor lead docking, internal control circuit wiring in control cabinets, sensor and actuator wiring;

Mobile devices: mobile electrical equipment with limited space such as RVs, emergency vehicles, and ships;

Other scenarios: internal wiring of household appliances, maintenance and modification of small electrical equipment.

Adapt to core requirements: Electrical connection scenarios that require compatibility with multiple wire types, pursuit of compact installation space, and emphasis on operational efficiency and installation safety.

Detailed explanation of core features and advantages

1. Compatible with all wire types, suitable for a wide range of specifications

Compatibility type: It supports solid wires, multi strand twisted wires, and flexible fine twisted wires without the need to replace connectors or adapter accessories, solving the adaptation problem of different wire connections.

Specification coverage:

Wire diameter (AWG standard): AWG 24-AWG 12 (corresponding to wire diameters of 0.2mm ² -4mm ², with a minimum support of 0.14mm ² for flexible wires);

Adaptation scenario: It can cover weak signal lines (such as sensor signal lines) to medium current power lines (such as small motor power lines).

Advantage value: Reduce spare parts inventory, one connector can meet multiple wiring needs, and reduce procurement and management costs.

2. Ultra compact design, optimizing space utilization

Volume upgrade: Compared to the 222 series, the overall volume has been reduced by 40%, and a single connector takes up less space.

Actual benefits: In space limited scenarios such as junction boxes and equipment interiors, more redundant space can be saved, which can accommodate more line connections and facilitate line sorting during later maintenance.

Installation flexibility: With its compact size, it supports multi-directional installation and can be flexibly arranged in narrow gaps and dense circuits.

3. Transparent shell design, visual security guarantee

Core function: The shell is 100% transparent, allowing for intuitive observation of two key installation points:

Wire insertion status: Confirm whether the wire is fully inserted into the designated position to avoid poor contact caused by "virtual connection" or "half insertion";

Compliance of wire stripping length: Quickly verify whether the wire stripping length meets the requirements to prevent short circuits caused by excessive stripping and poor contact caused by insufficient stripping.

Safety value: Through visual inspection, the installation error rate is reduced, and the cost of troubleshooting caused by wiring problems in the later stage is reduced. It is especially suitable for quality control in batch installation scenarios.

4. Upgrade operational convenience and reduce labor costs

Leverage operation optimization: The operating force for lever opening and closing is significantly lower than that of the 222 series, making the operation more effortless and suitable for long-term, large-scale wiring scenarios (such as construction project wiring).

Grip design: There is a concave grip area on the side, which increases the friction between the hand and the connector. Even when operating with gloves, it can be stably grasped to avoid slipping.

Tool free feature: No additional tools such as pliers or screwdrivers are required. The wire can be clamped and disassembled by manually opening and closing the lever, simplifying the operation process and improving installation efficiency.

Reusable: Supports multiple opening and closing operations, adapts to scenarios that require repeated disassembly and assembly such as temporary wiring, line adjustment, and equipment maintenance, and improves product reuse.

5. Practical functional design, adapted to meet the needs of multiple scenarios

Dual test slot design: Both the front and rear ends of the connector are equipped with test slots. Regardless of the installation direction or the density of surrounding circuits, test probes can be easily inserted, making it convenient for debugging operations such as conductivity testing and voltage measurement after installation.

High contrast label: The transparent shell is printed with black technical parameter labels (such as voltage, current, wire specifications), which are clear and easy to read, making it convenient for installation personnel to quickly confirm whether the product is suitable for the current scene and avoid model misuse.

Shell protection performance: The shell is made of high-strength engineering plastic, which has a certain degree of dust and light collision resistance, and is suitable for indoor and outdoor general electrical environments (non waterproof design, not suitable for humid or underwater scenes).

Product model and specification parameters

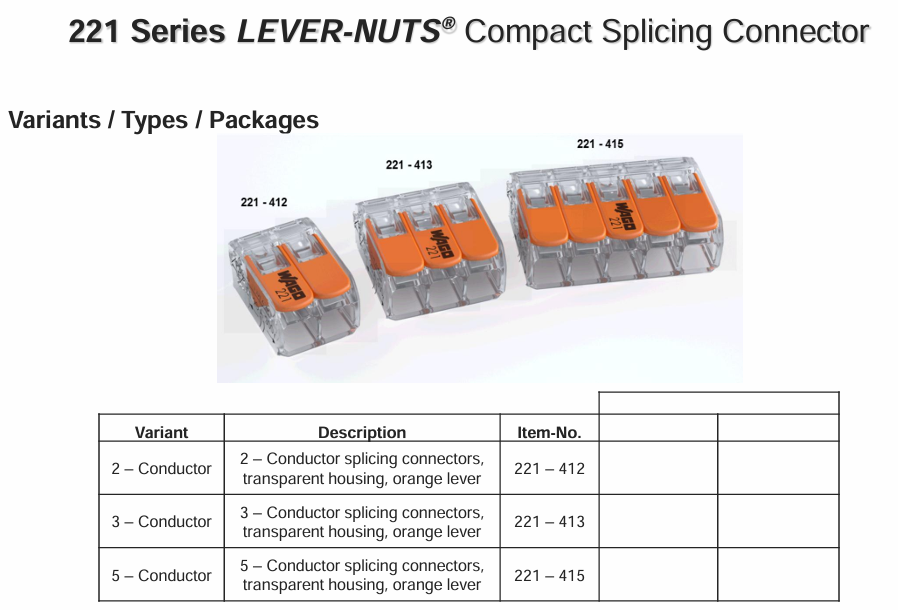

1. Product model and core configuration

Model, number of wire cores, shell color, lever color, core configuration features

221-412 2-core transparent orange dual wire channel, compatible with 2-channel wire splicing

221-413 3-core transparent orange three wire channel, compatible with 3-channel wire splicing

221-415 5-core transparent orange five wire channel, compatible with 5-wire splicing

Packaging form: All are individually packaged and supplied in bulk according to standard specifications (the standard packaging specification is 100 pieces/box, subject to the supplier's configuration).

2. Key technical parameters (based on international standards)

Technical indicators UL standard (North American market) ENEC standard (European and global markets) Remarks

Rated voltage 600V 450V, suitable for different regional power grid voltage standards

The maximum rated current of 20A 32A is determined based on the wire diameter and heat dissipation conditions

Maximum operating temperature 105 ° C T-Mark 85 ° C, suitable for high temperature environments (such as inside equipment)

Solid wire adaptation range AWG 24-AWG 12 0.2mm ² -4mm ² wire diameter correspondence: AWG24 ≈ 0.2mm ², AWG12 ≈ 4mm ²

Multi strand wire adaptation range AWG 24-AWG 12 0.2mm ² -4mm ² supports multi strand wires with twisted strands ≤ 36 strands

Flexible wire adaptation range AWG 24-AWG 12 0.14mm ² -4mm ² Suitable for fine twisted flexible wires (such as motor leads)

Contact resistance ≤ 5m Ω (initial value) ≤ 5m Ω (initial value) ensures low loss conductivity and reduces heat generation

Insulation resistance ≥ 100M Ω (500V DC) ≥ 100M Ω (500V DC) to ensure insulation performance and avoid leakage risk

3. Physical and mechanical properties

Shell material: transparent polycarbonate (PC), with high strength, impact resistance, and high temperature resistance characteristics;

Leverage material: Orange engineering plastic, with good mechanical strength and fatigue resistance (can be opened and closed repeatedly ≥ 100 times);

Conductive component material: high conductivity brass, surface treated with tin plating to enhance conductivity and oxidation resistance;

External dimensions (taking the 2-core model as an example): length x width x height ≈ 22mm x 12mm x 8mm (specific subject to the actual product);

Installation method: There is no fixed installation requirement, it can be freely placed in the junction box or fixed to the wiring harness with zip ties.

Product core advantages and competitive differences (compared to the 222 series)

Compare the core upgrade points of WAGO 221 series and WAGO 222 series (previous generation products) in terms of dimensions

The product has a small volume (reduced by 40% compared to the previous generation), which greatly improves space utilization and is suitable for narrow scenarios

Low operating force (lever operation is more effortless) reduces the manual intensity of batch installation to a moderate extent

The shell design is fully transparent, supporting visual inspection of semi transparent/opaque installation to enhance safety and facilitate quality control

The test slot is designed with dual front and rear test slots, with no directional restrictions and a single test slot. There are installation direction requirements to improve debugging convenience

Grip design with concave side grip area, no dedicated grip design, improved operational stability, and anti glove slippage

Installation and usage precautions

1. Installation steps

Wire processing: According to the connector identification requirements, strip the insulation layer of the wire (recommended stripping length 8-10mm, matching the length of the internal wiring terminal of the connector);

Leverage opening: Pull up the orange lever of the connector to 90 °, and the internal clamping mechanism will open, entering the wire insertion state;

Wire insertion: Fully insert the processed wire into the corresponding wiring hole of the connector, ensuring that the metal core of the wire is completely in contact with the internal conductive components and there is no insulation layer extending into the wiring hole;

Clamping and fixing: Press the lever down to the closed state, and hearing a "click" sound indicates that the clamping is in place and the wire is reliably fixed;

Visual inspection: Confirm through the transparent shell that the wire insertion depth and stripping length are compliant, and there is no exposed core wire or insulation layer clamping situation;

Test verification: Insert probes into the front and rear test slots for conductivity or voltage testing to confirm proper connection.

2. Key points for safe use

Voltage and current limitations: strictly follow the rated voltage (600V/450V) and maximum current (20A/22A) specified in UL/ENEC standards to avoid overloading causing heating or damage;

Environmental temperature requirements: Use within the temperature range of -40 ° C-105 ° C (UL standard)/85 ° C (ENEC standard) to avoid shell embrittlement or seal failure caused by high or low temperature environments;

Wire adaptation requirements: It is not allowed to insert wires beyond the specification range, or wires without stripped insulation layer, to avoid poor contact, short circuit or connector damage;

Installation environment: Avoid use in damp, dusty, and corrosive gas environments. If installation is required in such environments, protective enclosures or sealing measures must be taken in conjunction;

Reuse restriction: Although it supports reuse, it is recommended to disassemble and assemble it no more than 100 times to avoid lever fatigue or internal clamping mechanism failure.

Product delivery and procurement information

1. Packaging specifications

Conventional packaging: 100 pieces/box, each box containing product certification and installation instructions;

Batch packaging: 1000 pieces/box (suitable for engineering bulk procurement), packaged in moisture-proof and pressure resistant cardboard boxes.

2. Quality certification and warranty

Core certification: UL certification (North American market access), ENEC certification (European market access), in compliance with IEC 60998-2-2 standard (safety standard for low-voltage electrical connectors);

Warranty period: The product comes with a 2-year quality guarantee after leaving the factory. Under normal usage conditions, any malfunctions caused by material or manufacturing defects can be replaced free of charge.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923