K-WANG

Bently Nevada 3500/50M tachometer module

Bently Nevada 3500/50M tachometer module

The Approximately Nevada 3500/50M tachometer module is a dual channel module designed specifically for mechanical equipment condition monitoring. It can receive signals from proximity probes or magneto electric sensors, enabling real-time monitoring of shaft speed, rotor acceleration, and rotation direction. It triggers alarms through programmable alarm thresholds and is widely used in rotating machinery such as industrial turbines, generators, and compressors. It also supports providing conditioned Keyphasor signals to the 3500 rack backplane without the need for additional Keyphasor modules.

Core functions and positioning

1. Core monitoring capability

The module supports four types of monitoring configuration schemes, which can be flexibly selected according to the scenario, covering key parameters such as speed, acceleration, and direction:

Configuration plan, monitoring parameters, applicable scenarios

Option 1: Speed monitoring, threshold alarm, and speed bandwidth alarm for devices that need to monitor the range of speed fluctuations (such as generators)

Scenario 2: Speed monitoring, threshold alarm, and zero speed notification require determining the start/stop status of the equipment (such as compressor start/stop confirmation)

Plan 3: Equipment for speed monitoring, threshold alarm, and rotor acceleration alarm to prevent sudden increase/decrease in speed (such as turbine overspeed acceleration prevention)

Option 4: Speed monitoring, threshold alarm, and reverse rotation notification for devices that prohibit reverse rotation (such as pump type mechanical anti reverse protection)

2. Featured Features

Keyphasor signal sharing: It can be configured to output conditioned Keyphasor signals to the 3500 rack backplane for use by other monitoring modules (such as vibration monitoring modules), reducing the number of modules in the rack.

Peak holding: Automatically stores the highest forward speed, highest reverse speed, and number of reversals during device operation. The peak can be manually reset for easy fault tracing.

Flexible alarm configuration: Supports two-level alarms (Alarm 1/Alarm 2), and the alarm threshold and delay time can be set by software to avoid false alarms (such as short-term speed fluctuations not triggering alarms).

Technical parameters

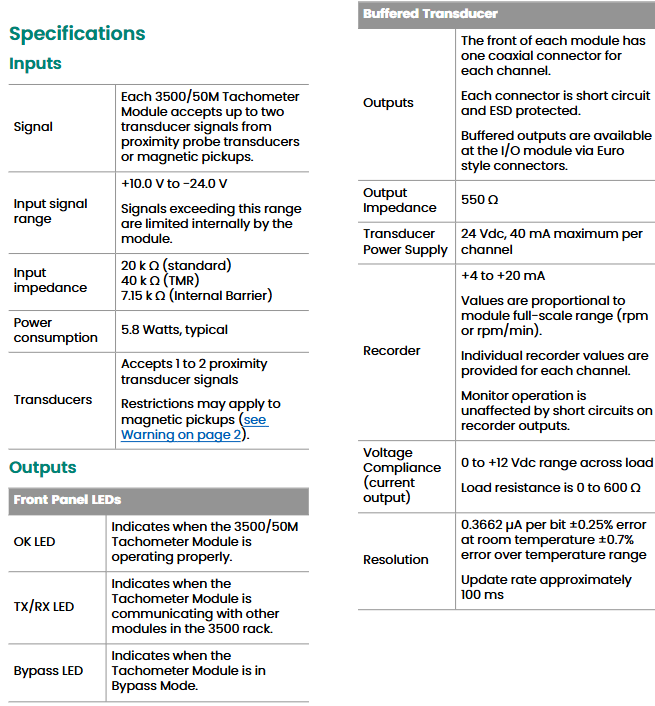

1. Input parameters

The module is compatible with two types of sensors, and attention should be paid to the usage restrictions of magneto electric sensors (see "Safety Warning"):

Parameters, specifications, and notes

The input signal source is close to the probe (recommended), and the magneto electric sensor does not support reverse monitoring or zero speed monitoring (the signal edge is unclear at low speeds, making it easy to misjudge)

The input signal range is+10.0V~-24.0V. If the signal exceeds the range, it is limited internally by the module to avoid damage

Input impedance standard: 20k Ω; TMR (Triple Modular Redundancy): 40k Ω; Built in isolation barrier: 7.15k Ω, suitable for different system requirements with different configurations

Minimum input frequency close to the probe: 0.0167Hz (1rpm, 1 pulse/rev); Magnetic electric sensor: 3.3Hz magnetic electric sensor does not support low-speed monitoring

The maximum input frequency of 20kHz corresponds to a maximum speed of 99999rpm (matching the number of pulses per revolution)

Number of pulses per revolution, rotor acceleration/zero speed channel: 1-255 pulses per revolution; Other channels: 0.0039~255 pulses per revolution, suitable for speed measuring gears with different numbers of teeth

2. Output parameters

Covering status indication, signal buffering, recording output, etc., to meet monitoring and data recording requirements:

Output type, specification, and function

Front panel LED OK (normal operation), TX/RX (rack communication), Bypass (bypass mode) intuitively judge the working status of the module

Buffer sensor output with 1 coaxial connector per channel (short circuit, ESD protection) for sensor signal multiplexing (such as simultaneous access to oscilloscope debugging)

The sensor power supply is 24VDC, with a maximum of 40mA per channel to provide power for the proximity probe

The recorder outputs a current signal proportional to the full range, with a resolution of 0.3662 µ A/bit, used for data recording and trend chart drawing. Short circuits do not affect module operation

Current output voltage range 0~+12VDC, load resistance 0~600 Ω, suitable for most industrial recorders

Output update rate of approximately 100ms to ensure real-time performance while avoiding data redundancy

3. Accuracy and alarm parameters

Parameters and specifications

Speed accuracy<100rpm: ± 0.1rpm; 100~10,000rpm:±1rpm; 10000~999999rpm: ± 0.01% true speed

Acceleration accuracy ± 20rpm/min

Alarm threshold range 0~100% full scale (software adjustable)

Alarm delay Alarm 1:1~60 seconds (1-second step); Alarm 2:1~60 seconds (0.1 second step size)

Alarm hysteresis 0.2~2.5V (user selectable to prevent frequent switching of alarms)

4. Physical and power consumption parameters

Module type, size (height x width x depth), weight, rack occupancy

Main monitoring module 241.3mm × 24.4mm × 241.8mm (9.50in × 0.96in × 9.52in) 0.82kg (1.8lb) 1 full height front slot

Non barrier I/O module 241.3mm × 24.4mm × 99.1mm (9.50in × 0.96in × 3.90in) 0.20kg (0.44lb) 1 full height rear slot

I/O module with isolation barrier 241.3mm × 24.4mm × 163.1mm (9.50in × 0.96in × 6.42in) 0.46kg (1.01lb) 1 full height rear slot

Typical power consumption is 5.8W --

Safety Warning and Compliance Certification

1. Critical safety warnings

Prohibited as an overspeed protection system: The module does not have redundant protection and sufficient response speed, and cannot be used alone or as a component for speed control systems or overspeed protection systems (such as turbine overspeed shutdown); Analog output is only used for data recording, plotting, or display, and alarms are only used for alarm notification and do not have safety interlock function.

Limitations of magnetic electric sensors: Magnetic electric sensors cannot be used for reverse rotation monitoring and zero speed monitoring. At low speeds, the sensor output signal has no clear edges, which can cause misjudgment of the rotation direction.

Installation in hazardous areas: I/O modules with isolation barriers must be installed according to the specified drawings (138547, 149243/149244) to ensure compliance with hazardous area certification requirements and avoid safety risks.

2. Compliance certification

The module complies with multiple international standards and is suitable for industrial scenarios in different regions around the world

Certification category, compliance standards/directives, scope of application

EMC (Electromagnetic Compatibility) EU EMC Directive 2014/30/EU; EN 61000-6-2 (Industrial Immunity), EN 61000-6-4 (Industrial Emissions) European and globally recognized EMC standards regions

Electrical Safety EU Low Voltage Directive 2014/35/EU; EN 61010-1 Electrical Safety Requirements for Industrial Environments

Environmental Protection EU RoHS Directive 2011/65/EU restricts the use of hazardous substances

Maritime certification DNV GL classification society rules (ships, offshore platforms); ABS Classification Society Rules (Steel Ships, Marine Structures) for Maritime Ships, Marine Platform Equipment

Hazardous Area Certification cNRTLus: Class I, Division 2 (Groups A-D, T4); ATEX/IECEx: II 3G (Ex nA nC ic IIC T4 Gc) explosive environment (such as petrochemical workshops)

Configuration and ordering information

1. Configuration requirements

The specified version of firmware and software must be used to ensure compatibility between the module and the 3500 system

Firmware/software, minimum version, remarks

3500/50M module firmware Revision 5.30 module core firmware determines functional availability

3500/22M module firmware Revision 1.70 firmware for rack communication

3500/01 configuration software Version 4.20 is used for module parameter configuration (such as alarm threshold, sensor type)

3500/02 Data Collection Software Version 2.52 is used to collect module monitoring data

3500/03 Display Software Version 1.52 is used for local or remote display of monitoring data and alarms

Incompatible module 3500/20 (all versions) cannot be shared with 3500/20 module in the same rack

2. Ordering models and accessories

(1) Module model (3500/50-AA-BB)

AA (I/O module type): 01=I/O module with internal terminals; 02=I/O module with external terminal; 04=I/O module with built-in isolation barrier and internal terminals.

BB (hazardous area certification): 00=no certification; 01=cNRTLus certification (Class I, Division 2); 02=ATEX/IECEx/CSA certification (Class I, Zone 2).

(2) Key accessories

Accessory type, model, description

External terminal block (ET Block) 125808-05 tachometer ET block (European connector)

128015-05 Tachometer ET Block (Terminal Block Connector)

128702-01 Recorder ET Block (European connector)

128710-01 Recorder ET Block (Terminal Block Connector)

Signal cable 135101-AAAA-BB tachometer signal to ET block cable (AAAA=length: 0005=5 feet/1.5 meters, 0010=10 feet/3.0 meters, etc.); BB=assembly status: 01=not assembled, 02=assembled)

129529-AAAA-BB recorder output to ET block cable (same specifications as signal cable)

Spare part 288062-02 3500/50M module complete machine

133442-01 I/O module with internal terminal

136703-01 Discrete I/O Module with Built in Isolation Barrier and Internal Termination

134938 3500/50M User Guide

Installation and usage precautions

Sensor selection: Reverse monitoring and zero speed monitoring must use proximity probes, and the use of magneto electric sensors is prohibited; During installation, ensure that the clearance between the proximity probe and the speed measuring gear meets the requirements (usually 0.25-1.0mm) to avoid weak or distorted signals.

Wiring specifications: I/O modules with external terminals require separate ordering of external terminal blocks and cables; Different types of I/O modules cannot be mixed (for example, internal and external terminal modules cannot be shared on the same channel).

Installation in hazardous areas: Modules with isolation barriers must be wired according to specified drawings (such as 138547) to ensure effective isolation barriers and avoid safety risks in explosive environments.

Peak reset: After equipment maintenance, it is necessary to manually reset the peak value to maintain data and avoid the influence of old peak values on fault diagnosis.

Software configuration: For the first use, the 3500/01 configuration software needs to be used to set parameters such as the number of pulses per revolution, alarm threshold, delay time, etc., to ensure that they match the actual operating parameters of the equipment (such as the number of teeth on the speed measuring gear).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923