K-WANG

BENDING 77 Series Electric Bender with Single Shoe Groups

BENDING 77 Series Electric Bender with Single Shoe Groups

Product Overview

The Current Tools 77 series electric pipe bending machine is a professional equipment designed specifically for industrial pipeline installation. It features "single shoe adaptation to multiple specifications, sturdy structure, and easy maintenance", and can meet the bending needs of different types of pipelines (EMT, IMC, Rigid, PVC coated Rigid) ranging from 1/2 "to 2". It is widely used in construction, electrical installation, and other scenarios. The product is manufactured in the United States, with strict quality control and a two-year warranty. The core electrical components are the same as the 747 Omni of the same brand ™ The pipe bending machine is interchangeable, reducing maintenance costs.

Product model and core configuration

(1) Host model classification

Host model, compatible with pipeline type, including component weight, UPC code

77 without (power unit only) electric power source (without boots and roller bracket) 270 lbs 811993020261

77SR 1/2 "-2" Rigid Pipe Power Unit+Rigid Single Shoe+Rigid Roller Bracket 334 lbs 811993025495

77SI 1/2 "-2" IMC pipeline power unit+IMC single boot+IMC roller bracket 369 lbs 811993025501

77SE 1/2 "-2" EMT pipeline power unit+EMT single boot+EMT roller bracket 361 lbs 811993025518

77SP 1/2 "-2" PVC coated Rigid pipe power unit+PVC coated Rigid single boot+corresponding roller bracket 330 lbs 811993025525

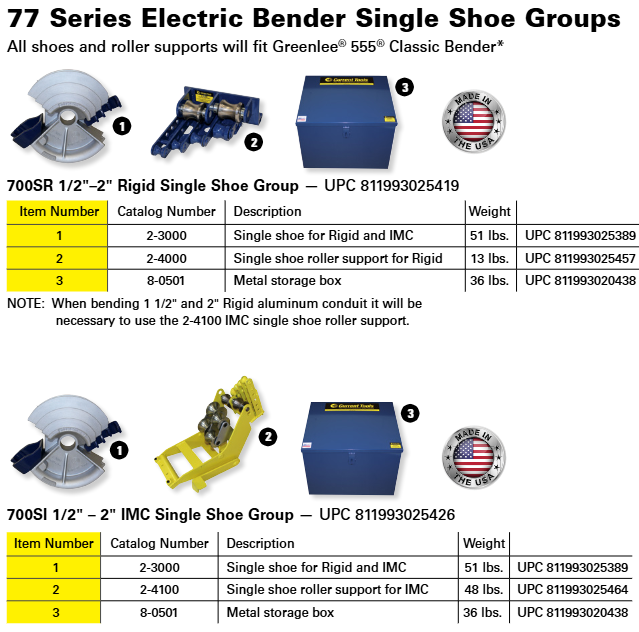

(2) Single boot model and components

All single boot sets include "single boot+roller bracket+metal storage box" and are compatible with Greenlee ® five hundred and fifty-five ® The classic pipe bending machine has the following specific configuration:

Shoe set model, compatible with pipeline type, component details (including model), weight of each component, total UPC code

700SR 1/2 "-2" Rigid 1. Single boot (2-3000); 2. Roller bracket (2-4000); 3. Metal storage box (8-0501) single boot 51 lbs; Roller bracket 13 lbs; Storage box 36 lbs 811993025419

700SI 1/2 "-2" IMC 1. Single boot (2-3000); 2. Roller bracket (2-4100); 3. Metal storage box (8-0501) single boot 51 lbs; Roller bracket 48 lbs; Storage box 36 lbs 811993025426

700SE 1/2 "-2" EMT 1. Single boot (2-3100); 2. Roller bracket (2-4200); 3. Metal storage box (8-0501) single boot 43 lbs; Roller bracket 48 lbs; Storage box 36 lbs 811993025433

700SP 1/2 "-2" PVC coated Rigid 1. Single boot (2-3200); 2. Roller bracket (2-4300); 3. Metal storage box (8-0501) with a single boot weighing 47 lbs; Roller bracket 13 lbs; Storage box 36 lbs 811993025440

Special note: When bending 1 1/2 "and 2" Rigid aluminum pipes, an IMC single shoe roller bracket (model 2-4100) is required.

Core technical parameters

(1) Basic parameters

Parameter category specific specifications

Power requirement: 120V AC, 20A GFCI protective socket (220V version requires consultation with the factory)

Equipment dimensions: height 42 ", width 29.5", depth 24.5“

The working temperature is not clearly marked (suitable for industrial conventional environments)

Warranty period of two years

(2) Bending radius specifications (classified by pipeline size)

Pipeline size EMT bending radius IMC bending radius Rigid bending radius

1/2" 4 5/16" 4 1/4" 4 1/4"

3/4" 5 1/2" 5 7/16" 5 7/16"

1" 7" 6 15/16" 6 15/16"

1 1/4" 8 13/16" 8 3/4" 8 3/4"

1 1/2" 8 3/8" 8 1/4" 8 1/4"

2" 9 1/4" 9" 9"

Core product features

Structural design advantages:

No PC board design: using simple and reliable electrical components to reduce the probability of electronic failures and improve equipment stability.

Detachable handle: supports doggle bends, suitable for pipeline forming requirements in complex installation scenarios.

Non inflatable wheels: convenient for equipment movement and reduce on-site maintenance frequency.

Compatibility and maintainability:

Shoe set compatibility: All single boots and roller mounts can be adapted to Greenlee ® five hundred and fifty-five ® Classic pipe bending machine enhances the versatility of accessories.

Component exchange: Main electrical components and Model # 747 Omni ™ The pipe bending machine is interchangeable, reducing the cost of spare parts procurement.

Easy to maintain: With a simple structure and convenient troubleshooting, basic maintenance can be completed without the need for professional skills.

Manufacturing and Quality:

Made in the United States: Following strict industrial production standards to ensure equipment durability and service life.

Two year warranty: covering the core components of the host, providing users with long-term use guarantee.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923