+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

GE 8752-CA-NS Universal Node Services Carrier

GE 8752-CA-NS Universal Node Services Carrier

GE 8752-CA-NS Universal Node Services Carrier

GENERAL

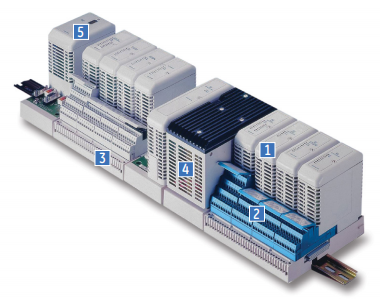

PAC8000 I/O is a completely modular I/O

solution for both general purpose and

hazardous area applications. Based upon

a carrier system that supports a range of

modules, it offers a wide variety of I/O functions, including AC mains and intrinsic safety

signals - even within the same node. It has an

“open” architecture that allows communication with a variety of different field-buses by

selecting the appropriate type of Bus Interface Module (BIM) or Controller.

I/O Modules

I/O modules transfer signals to and from field

instruments. Input modules receive signals

from transmitters and sensors and convert

them into a digital form for presentation to

the BIM or Controller. Output modules receive

commands from the BIM or Controller and

transfer them to actuators. A wide range

of modules is available, including types for

low-level instrumentation, AC mains and

intrinsically safe signals. I/O modules can

have 4, 8, 16, or 32 field channels.

Field terminals

Field terminals provide the interface between

the I/O modules and the field wiring. They

include fusing and loop disconnect as options.

A mechanical keying system helps prevent

an I/O module from being connected to the

wrong type of field terminal. Field terminals

mount onto the module carrier, one to each

I/O module. They are clamped firmly by the

I/O module to form an electrical and mechanical assembly of high integrity. They may be

replaced in service without removing carriers

or disturbing the operation of other modules.

Carriers

Carriers form PAC8000’s physical and electrical backbone by providing a mounting

onto a flat panel or T- or G-section DIN rail.

They support and interconnect the BIM or

Controller, power supplies, I/O modules and

field terminals, and carry the address, data

and power lines of the internal Railbus.

They provide a termination points for the

LAN and field wiring cable screens and can

also distribute bussed field power to the I/O

modules. I/O module carriers are available to

support four or eight I/O modules.

Power supplies

Good power management lies at the heart

of a true distributed I/O system. 8000 power

supplies accept locally available unregulated

power and provide a regulated supply for the

BIM or Controller and I/O modules. Supply

redundancy is supported.

Bus Interface Module (BIM)

The BIM provides a serial data connection

to a host controller, which could be a distributed control system (DCS), a programmable

logic controller (PLC), or a PC running a soft

control package. A choice of BIMs allows you

to accommodate the most popular fieldbus

protocols. The BIM also uses a fast internal

bus to pass data to, and obtain data from,

the I/O modules. Only one BIM is required at

each node to control up to 64 I/O modules.

Controllers

Controllers are an alternative to BIMs - and

are used where distributed control is required,

rather than distributed IO. A number of

different Controllers are available which

are suited to particular applications. The

Logic Controller runs applications based on

IEC61131 languages, the Process Controller

has a control package that uses DCS-style

function blocks and the Hybrid Controller can

run both application packages in a single unit.

The SafetyNet Controller is SIL 2 compliant

for emergency shut-down and fre and gas

applications. The RTU Controller runs IEC61131

application programmes and supports DNP3

communication protocol.

“HART-ability”

The use of ‘smart’ instruments on process

plants is growing but this investment is not

always fully exploited. Whether it is for a new

installation, or the upgrade of an existing

one, we have solutions that provide the

connections between the HART field instruments, the control systems and the asset

management software.

Specifically, the PAC8000 Process I/O system

has been designed to be transparent to

HART signals, thus allowing the host control

software and any HART field instruments to

communicate directly with each other.

In addition, PAC8000’s HART connection

system provides on-line access from a PC to

the HART field devices for monitoring device

performance. HART devices may be selected

for regular status monitoring and alerts can

be issued if the status changes. The benefits

from this approach are:

• Reduced commissioning time and cost

• Reduced process downtime through status

monitoring

• Lower loop maintenance costs by using

field device diagnostics

8000 in your system

Figure 1 shows two possible methods for

linking the 8000 into a system. On the left is

a host controller system that uses fieldbus as

the main distribution medium. On the right

is a section of a typical DCS/PLC informa tion network, with an operator station that

uses a separate interface to the process

fieldbus. The number of 8000 nodes that

can be accommodated depends upon the

addressing capability of the fieldbus in use.

Each 8000 node can address 32 I/O modules

which, depending upon the number of chan nels per module, can provide up to 512 I/O

points at a single node! A node can consist

of a mixture of analog and discrete modules

and this gives maximum flexibility to the

system designer. Where supported by the

fieldbus, full HART pass-through is provided—

the 8000 appears “transparent”, allowing the

host controller to access the HART capabili ties of field instruments.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

91

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923