K-WANG

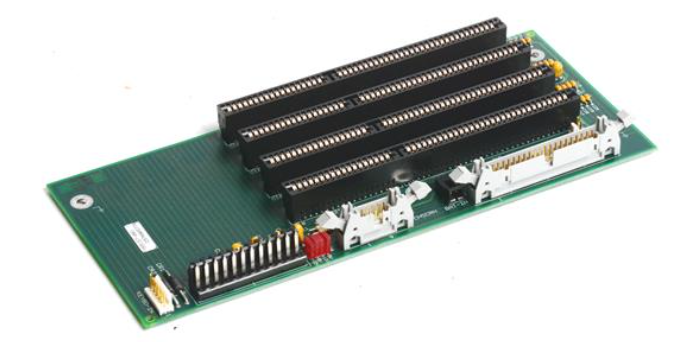

XYCOM 92023-001 DMA 90440C 1592 CIRCUIT board

XYCOM 92023-001 DMA 90440C 1592 CIRCUIT board

Product Overview

The XYCOM 92023-001 DMA 90440C 1592 circuit board is a high-performance circuit board designed by XYCOM specifically for industrial control and data processing scenarios. In complex systems such as industrial automation, data acquisition and transmission, stable and efficient data transmission and processing capabilities are the key to ensuring the normal operation of the system. This circuit board, with its direct memory access (DMA) technology, can achieve fast data transfer, reduce CPU load, and improve overall system efficiency. It is the core component of data exchange and processing in industrial control systems and is widely used in industrial fields that require high-speed data processing and stable transmission.

Specification parameters

Circuit board type: Industrial Control and Data Processing Circuit Board

Core technology: Direct Memory Access (DMA) technology

Data transmission rate: High speed transmission can be achieved according to system configuration

Interface type: Suitable for multiple industrial standard interfaces (such as PCI, VME, etc., depending on product design)

Working voltage: meets industrial standard voltage requirements (such as+5V, ± 12V, etc.)

Power consumption: Low power design, typical power consumption

Working temperature range: -20 ℃ -60 ℃

Storage temperature range: -40 ℃ -85 ℃

Core functions

(1) High speed data transmission

Based on direct memory access (DMA) technology, the XYCOM 92023-001 DMA 90440C 1592 circuit board can directly transfer data between external devices and memory without the need for frequent CPU involvement in the data transfer process. In industrial automation production lines, a large amount of data collected by sensors needs to be quickly transmitted to the control system for processing. This circuit board can achieve high-speed data transmission, ensuring timely and accurate delivery of data to the target location, providing strong support for real-time decision-making of the control system, effectively improving production efficiency and equipment response speed.

(2) Multi device compatibility

Equipped with multiple industrial standard interfaces, it can seamlessly connect with various industrial equipment such as sensors, actuators, controllers, etc. Whether in complex industrial control system integration or equipment upgrade and renovation projects, it can be easily integrated into the system, work together with other devices, meet diverse equipment connection requirements in different industrial scenarios, and enhance system compatibility and scalability.

(3) Stable and reliable operation

Adopting high-quality electronic components and optimized circuit design, it has undergone rigorous industrial testing and verification, and has excellent anti-interference ability and environmental adaptability. In harsh industrial environments such as high temperature, high humidity, and strong electromagnetic interference, stable data transmission and processing performance can still be maintained, effectively reducing the risk of system downtime caused by circuit board failures and ensuring the continuity and stability of industrial production.

Working principle

When external devices generate data that needs to be transmitted, the DMA controller of XYCOM 92023-001 DMA 90440C 1592 circuit board first obtains bus control. Subsequently, the DMA controller establishes a data transfer channel directly between the external device and the memory based on preset transfer parameters such as source address, destination address, and transfer data length. During data transmission, the DMA controller is responsible for managing data read and write operations without the need for CPU intervention, greatly reducing the burden on the CPU and allowing it to focus on other critical tasks.

After the data transfer is completed, the DMA controller releases bus control and sends a transfer completion interrupt signal to the CPU, notifying the CPU that the data has been successfully transferred to the designated memory area. After receiving the interrupt signal, the CPU can further process and analyze the transmitted data, realizing the data exchange and processing flow of the entire system, ensuring that the industrial control system can make decisions and control based on accurate data.

Key advantages

(1) Efficient performance

With DMA technology, data transfer efficiency is significantly improved, data transfer time is significantly reduced, and overall system operation efficiency is enhanced. In industrial scenarios that require extremely high data processing speed, such as high-speed data acquisition systems and real-time monitoring systems, large amounts of data can be quickly processed and transmitted to meet the efficient operation needs of industrial production, providing strong guarantees for enterprises to improve production efficiency and reduce production costs.

(2) Reliable and stable

Strictly follow industrial standards for design and manufacturing, with strict control over everything from component selection to production processes. Having excellent resistance to electromagnetic interference and a wide temperature range, it can adapt to various complex industrial environments, ensure stable and reliable performance during long-term continuous operation, reduce equipment maintenance and fault repair costs, and improve the reliability and stability of industrial production.

(3) Flexible Expansion

The rich interface types and modular design enable the circuit board to be easily integrated with different industrial equipment, meeting diverse industrial application needs. Users can flexibly configure the functions and connection devices of the circuit board according to actual project needs, easily achieve system upgrades and expansions, and provide good scalability and adaptability for the continuous development of industrial control systems.

Precautions

(1) Installation requirements

Before installing the circuit board, it is necessary to ensure that the device power is completely turned off and take anti-static measures, such as wearing an anti-static wristband, operating on an anti-static workbench, etc., to prevent static electricity from damaging the circuit board. During the installation process, it is necessary to strictly follow the instructions in the product installation manual, correctly insert the circuit board into the corresponding slot or interface, and ensure a secure connection to avoid abnormal data transmission or equipment failure caused by poor contact. At the same time, attention should be paid to the installation environment of the circuit board, which should be kept dry and well ventilated, avoiding installation in high temperature, humidity, dusty or corrosive gas environments to ensure the normal service life and performance of the circuit board.

(2) Usage standards

During use, it is strictly prohibited to arbitrarily change the hardware settings and parameter configurations of the circuit board. If adjustments are necessary, they must be carried out by professional technicians in a power-off state, following the instructions in the product manual. Avoid plugging and unplugging connecting cables or other devices during circuit board operation to prevent damage to circuit board components due to transient current surges. At the same time, it is necessary to ensure a stable and compliant power supply for the circuit board to avoid circuit board failures caused by power fluctuations or abnormalities.

(3) Maintenance and troubleshooting

Regularly clean and inspect the circuit board, use a dry, soft brush or compressed air to remove dust and debris from the surface of the circuit board, and prevent dust accumulation from affecting the heat dissipation and electrical performance of the circuit board. Check if there are any abnormal phenomena such as looseness, deformation, burning, etc. on the components on the circuit board, and if there are any damage, aging, or other issues with the connecting cables. If a fault is found in the circuit board, such as abnormal data transmission or inability to recognize the device, you can refer to the troubleshooting guide in the product manual for preliminary inspection and diagnosis. For more complex faults, it is recommended to promptly contact XYCOM's technical support personnel or professional maintenance personnel for handling. Do not disassemble the circuit board by yourself to avoid more serious damage.

Standard Features

The units offer the following standard features:

• 3.3-inch (9400T and 9400KP) and 3.5-inch (9410T and 9410KP) mounting depth

• Flat-panel displays

• 7.7-inch STN flat-panel display, 640x480 (9400T and 9400KP)

• 10.4-inch STN and TFT flat-panel displays (9410T and 9410KP)

• CHIP4e+ board, which supports the latest 5x86 technology

• 133 MHz AMD5x86 processor

• 72-pin EDO DRAM SIMM site support (4, 8, 16, 32, and 64 Mbytes)

• PCI 64-bit video controller, 1-Mbyte video RAM

• PCI-bus IDE controller

• 10BASE-T/100 BASE-TX Ethernet controller

• Numerous I/O ports

• RS-232 and RS-232/RS-485 COM ports

• Parallel port

• VGA port (9400N only)

• PS/2 mouse and keyboard ports

• IrDA-compatible infrared port

• AC input power

• Flash BIOS

• External floppy connector

• PC/104 expansion site, allowing you to stack two PC/104 boards

• Status LEDs: Power, Disk, and COM (9400T, 9410T, and 9400N) and Input (9400T and 9410T)

• MS-DOS (MS-DOS is not included if you order Windows ® 95 or WindowsNT ™)

• NEMA 4/4X/12 sealed front panel

• Class I, Division 2 hazardous location approval (pending)

The 9400KP and 9410KP also include function, control, numeric, alpha, and cursor control keypads.

Optional Features

The following optional features are available:

• Windows 95 or Windows NT preinstalled

• Windows NT touch screen driver (serial port only; included if Windows NT is or dered preinstalled)

• OS/2 touch screen driver (serial port only)

• Hot installable external floppy drive

• 4100-KB2 external full-stroke keyboard

• 4100 WIN Microsoft Windows version 3.11

• 8000-KBX sealed rack- and panel-mount keyboards

• 24-volt DC power supply

• 10- or 20-Mbyte IDE Flash drives

• NEMA 4-sealed panel-mount door for front access to keyboard and external floppy port connectors (with mounting hardware)

Unpacking the System

When you remove the system from its box, verify that you have the parts listed below.

Save the box and inner wrapping in the event you need to reship the unit.

• 9400T, 9400KP, 9400N, 9410T, or 9410KP

• Documentation kit:

• Power connector

• Diagnostic software disk (MS-DOS units only)

• Eight 8-32 hex nuts (9400s) or twelve 10-32 hex nuts (9410s)

• Cable clamp and screw (for strain relief of power cord)

• Four standoffs and four 4-40 screws for mounting PC/104 expansion cards

• 9400/9410 Series Industrial Mini-PC System manual

• CPU manual

• Utility disks

• Business reply card

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- xYCOM

- Construction site

- Siemens

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Motorola

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive