K-WANG

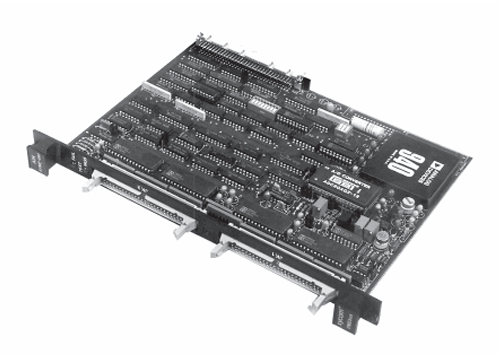

Xycom AIN XVME-560 Analog Input Module 70560-001

The XVME-560 can be programmed to operate in one of four operating modes: random channel, sequen tial channel, single-channel, or external-trigger mode.

After the completion of an A/D conversion, an optional interrupt may be generated.

The XVME-564 can sample unipolar and bipolar inputs, with voltage ranges of 0-5 V, 0-10 V, ±2.5 V,

±5 V, and ±10 V. Programmable gains of 1, 2, 4, or 8 may be software-selected.

Xycom AIN XVME-560 Analog Input Module 70560-001

Overview

The XVME-560 Analog Input Module is a powerful VMEbus-compatible analog input module capable of performing 12-bit A/D conversions on up to 64 different input channels.

The XVME-560 can be programmed to operate in one of four operating modes: random channel, sequen tial channel, single-channel, or external-trigger mode.

After the completion of an A/D conversion, an optional interrupt may be generated.

The XVME-564 can sample unipolar and bipolar inputs, with voltage ranges of 0-5 V, 0-10 V, ±2.5 V,

±5 V, and ±10 V. Programmable gains of 1, 2, 4, or 8 may be software-selected.

Features

• 64 single-ended or 32 differential channels

• 12-bit input resolution

• On-board DC/DC converter

• Jumper-selectable voltage ranges: 0-5 V,

0-10 V, ±2.5 V, ±5 V, and ±10 V

• Software-programmable gain: 1, 2, 4 or 8

• Can interrupt at any of seven VMEbus interrupt levels

Applications

• Slide wires

• Analytical equipment

• Microphones

• RTDs and thermistors

• Temperature transmitters

• Strain gauges and load cells

• Tach generators

Specification parameters

Number of channels: 16 single ended inputs or 8 differential inputs

Input signal range: Multiple selectable options including ± 10V, ± 5V, ± 2.5V, ± 1.25V, etc

Resolution: 12 bits

Sampling rate: up to 100kHz

Accuracy: ± 0.05% FSR (full range)

Isolation feature: There is photoelectric isolation between the channel and the system, with an isolation voltage of up to 1500Vrms

Data interface: Compliant with the VMEbus standard, easy to integrate into the VMEbus system

Power supply requirement:+5V DC, typical power consumption 1.5W

Working temperature range: 0 ℃ -55 ℃

Storage temperature range: -40 ℃ -85 ℃

Physical dimensions: Complies with VMEbus standard dimensions

Core functions

(1) Multi channel analog signal acquisition

Equipped with 16 single ended inputs or 8 differential input channels, capable of simultaneously collecting data from multiple analog signal sources. In industrial automation production lines, multiple types of sensors such as temperature sensors, pressure sensors, and flow sensors can be connected simultaneously to achieve real-time collection of key parameters such as temperature, pressure, and flow during the production process, providing a comprehensive data foundation for production monitoring and control.

(2) High precision signal conversion

A resolution of 12 bits and high precision of ± 0.05% FSR ensure accurate conversion of analog signals to digital signals. In scenarios such as scientific research experiment data collection and precision instrument measurement that require extremely high precision, the ability to accurately capture subtle changes in signals provides reliable data support for data analysis and decision-making, effectively avoiding data bias and decision-making errors caused by signal conversion errors.

(3) High speed sampling capability

With a sampling rate of up to 100kHz, it can quickly collect dynamically changing analog signals. In application scenarios such as motor control and vibration monitoring that require real-time tracking of rapidly changing signals, the latest status of the signals can be obtained in a timely manner, providing guarantees for rapid response and precise control of the system, and helping to improve the stability and reliability of equipment operation.

(4) Electrical isolation protection

1500Vrms optoelectronic isolation between channels and systems effectively isolates external interference signals, protecting modules and systems from electrical noise, overvoltage, and other factors. In complex industrial electromagnetic environments, it is possible to ensure the accuracy of data collection and the safe operation of modules, reduce the risk of system failures caused by electrical interference, and improve the stability of the entire industrial control system.

Working principle

The workflow of the Xycom AIN XVME-560 analog input module 70560-001 mainly includes four stages: signal input, conditioning, conversion, and output. When the analog signal from the sensor enters the module, it first goes through the input signal conditioning circuit. This circuit amplifies, filters, and adjusts the signal to a range suitable for A/D conversion based on the preset input signal range, while filtering out noise and interference components in the signal to improve signal quality.

After conditioning, the analog signal enters a 12 bit A/D converter, which converts continuous analog signals into discrete digital signals at a set sampling rate. During the conversion process, the analog signal is quantized and converted into binary digital codes, which represent the amplitude information of the analog signal.

After the converted digital signal is buffered and processed, it is transmitted to other devices in the VMEbus system, such as controllers and processors, through data interfaces that comply with the VMEbus standard. After receiving digital signals, these devices can further analyze, process, and store the data, thereby achieving monitoring and control of the physical quantities represented by analog signals.

Precautions

(1) Installation requirements

Before installing the module, it is essential to ensure that the VMEbus system is powered off to prevent electric shock and equipment damage. When installing, follow the instructions in the product manual to correctly insert the module into the VMEbus slot and ensure a secure connection to avoid abnormal data transmission caused by poor contact. At the same time, attention should be paid to the installation environment of the module, which should be kept dry and well ventilated, and avoid installation in environments with high temperature, humidity, dust or corrosive gases, so as not to affect the performance and service life of the module.

(2) Usage standards

During use, it is necessary to strictly set the input signal range and sampling rate parameters according to the specifications of the module to avoid exceeding the rated working range of the module and prevent module damage caused by overload or improper parameter settings. When connecting external devices such as sensors, ensure correct wiring, pay attention to signal polarity and electrical connection reliability, and prevent signal acquisition abnormalities or equipment failures caused by wiring errors.

(3) Maintenance and troubleshooting

Regularly inspect and maintain the module, including cleaning the dust on the surface of the module, checking for loose wiring, etc. If the module malfunctions, such as abnormal data collection or abnormal indicator lights, you can refer to the troubleshooting guide in the product manual for preliminary inspection and diagnosis. For more complex faults, it is recommended to contact Xycom's technical support personnel or professional maintenance personnel in a timely manner to avoid disassembling the module on your own and causing further damage

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- xYCOM

- Construction site

- Siemens

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Motorola

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive