K-WANG

ABB ACS880-01-025A-3 frequency converter

Structure type, power range, typical application scenarios, core characteristics

Wall mounted (Type 01) 0.55kW-75kW small and medium power single machine control (such as fans, water pumps, conveyor belts) with compact size, IP21 protection (preventing vertical dripping and solid foreign objects), natural cooling or forced air cooling, suitable for installation in control cabinets/dry environments

Cabinet style (04/06 type) 11kW-2800kW high-power or complex control (such as rolling mill, compressor, centrifuge) independent cabinet design, IP21/IP54 protection optional, built-in cooling system (air-cooled/water-cooled), integrated input circuit breaker, reactor and other accessories, supports multi machine linkage

Modular (02 type) 160kW-2800kW ultra high power scenarios (such as mine hoists, large fans) modular components (power modules, control units, auxiliary modules) that need to be matched with user made cabinets, support redundant design, and adapt to customized systems

ABB ACS880-01-025A-3 frequency converter

Product classification and structural design

The ACS880 series is divided into three categories based on installation method and power range, suitable for different industrial environment requirements:

Structure type, power range, typical application scenarios, core characteristics

Wall mounted (Type 01) 0.55kW-75kW small and medium power single machine control (such as fans, water pumps, conveyor belts) with compact size, IP21 protection (preventing vertical dripping and solid foreign objects), natural cooling or forced air cooling, suitable for installation in control cabinets/dry environments

Cabinet style (04/06 type) 11kW-2800kW high-power or complex control (such as rolling mill, compressor, centrifuge) independent cabinet design, IP21/IP54 protection optional, built-in cooling system (air-cooled/water-cooled), integrated input circuit breaker, reactor and other accessories, supports multi machine linkage

Modular (02 type) 160kW-2800kW ultra high power scenarios (such as mine hoists, large fans) modular components (power modules, control units, auxiliary modules) that need to be matched with user made cabinets, support redundant design, and adapt to customized systems

Electrical performance and speed regulation capability

The manual specifies the series of general electrical parameters, and the differences between different models are distinguished by the "model suffix" (such as voltage level, power code):

Input voltage range:

Low voltage series: 200-240V AC (single-phase/three-phase), 380-480V AC (three-phase), 500-690V AC (three-phase), all supporting ± 10% voltage fluctuation;

Frequency adaptation: 50/60Hz (± 5% fluctuation), compatible with global grid frequencies.

Output performance:

Output frequency: 0-500Hz (standard), 0-1000Hz (high frequency optional), supporting high-speed motor speed regulation;

Speed control accuracy: open-loop V/F control ± 0.5% rated speed, closed-loop vector control ± 0.1% rated speed;

Starting torque: 150% rated torque @ 0Hz under vector control (suitable for heavy-duty starting, such as crushers and extruders).

Control mode:

Basic mode: V/F control (square torque/constant torque curve optional, suitable for loads such as fans and pumps);

Advanced modes: sensorless vector control (no encoder required, suitable for scenarios without position feedback), closed-loop vector control (with encoder, high-precision speed regulation), torque control (constant torque output, such as curling equipment);

Special functions: synchronous control (multi motor speed/torque synchronization), process PID control (built-in PID regulator, directly related to process parameters such as pressure and flow), energy-saving mode (automatic optimization of voltage frequency ratio, reducing no-load losses).

Safety and protection functions

The manual emphasizes the safety design of the series, which complies with international safety standards such as IEC 61800-5-1. The core protection functions include:

Motor protection: overcurrent, overload (inverse time characteristic), locked rotor, phase loss, over temperature (supporting motor PTC thermistor connection), insulation monitoring;

Inverter protection: DC bus overvoltage/undervoltage, IGBT module overheating, input phase loss, output short circuit, ground fault (optional residual current detection), lightning surge protection;

System safety: Safe torque shutdown (STO, SIL2 certification, cutting off motor torque output in emergency situations), safe stop (SS1/SS2, compliant with EN ISO 13850), adapted to industrial safety circuit design.

Communication and integration capabilities

The ACS880 series supports multi protocol communication, making it easy to connect to PLC, DCS, or upper computer systems. The manual provides detailed instructions on the configuration methods for each protocol

Standard communication: RS485 interface (supporting Modbus RTU protocol), used for local small-scale communication;

Optional modules: Profinet, EtherNet/IP, DeviceNet, CANopen, Profibus DP and other industrial Ethernet modules to achieve high-speed remote monitoring and multi device linkage;

ABB exclusive protocol: Supports ABB DriveBus and can quickly network with ABB PLC (such as AC500) or other ACS880 frequency converters, simplifying synchronous control configuration.

Manual Key Operation Guide (Installation, Debugging, and Maintenance)

1. Installation and wiring specifications

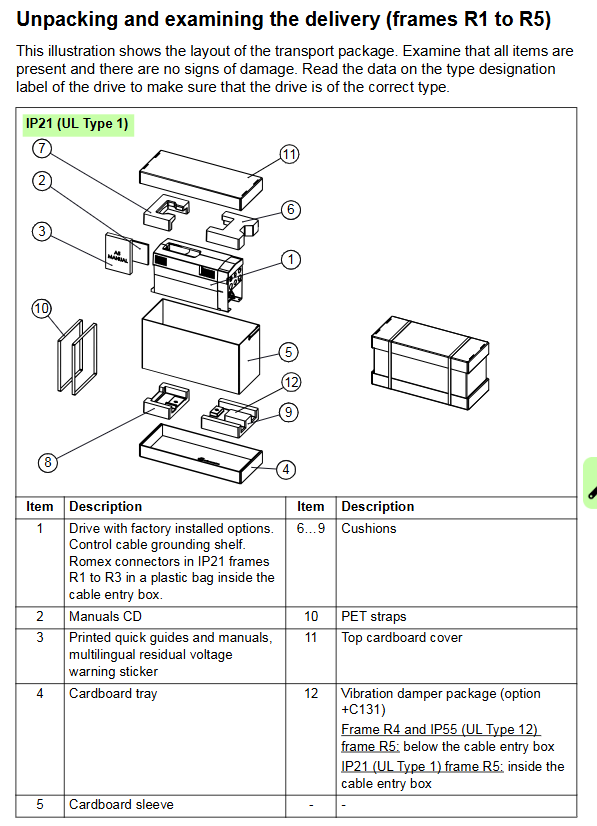

The manual specifies the prerequisites for safe installation (such as power-off operation, electrostatic protection) and core steps:

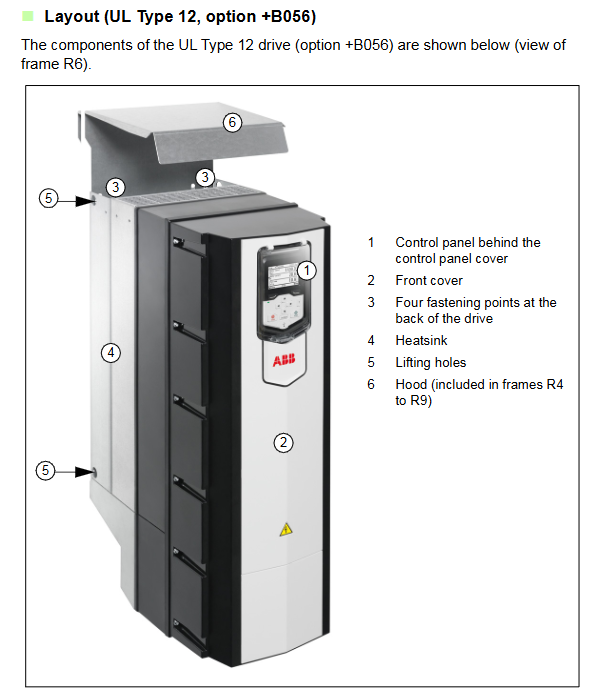

Installation environment requirements: working temperature -25~40 ℃ (some models can be extended to -40~50 ℃), relative humidity 5% -95% (no condensation), altitude ≤ 1000m (reduced capacity is required for use at high altitudes), away from dust, corrosive gases, and strong electromagnetic interference sources;

Wiring points:

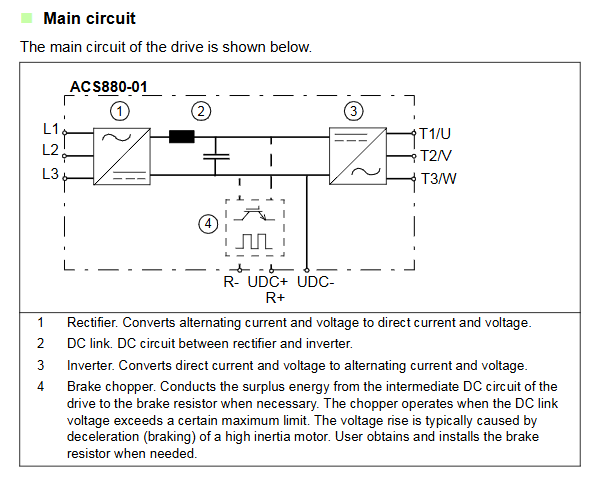

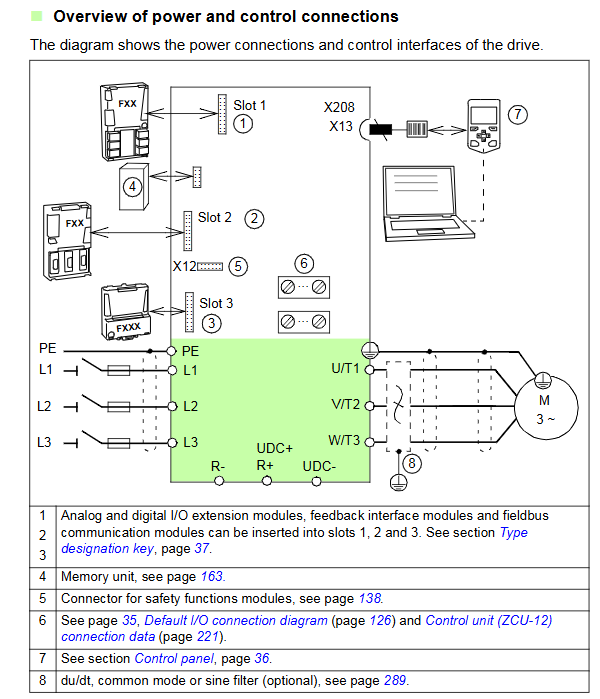

The main circuit (input L1/L2/L3, output U/V/W) needs to match the cross-sectional area of the wires (according to the rated current), and install input circuit breakers and reactors (to suppress harmonics, optional);

Shielded wires are required for control circuits (analog I/O, digital I/O, encoder interfaces), with the shielding layer grounded at one end to avoid parallel laying with the main circuit cable (reducing interference);

The safety circuit (STO, emergency stop) needs to be independently wired to ensure that protection is triggered first in case of a fault.

2. Debugging process and parameter configuration

The manual provides standardized debugging steps, suitable for most application scenarios:

Pre power on inspection: Confirm correct wiring (no short circuit, virtual connection), grounding resistance ≤ 4 Ω, parameter reset (default factory settings);

First power on: first turn on the control power supply (check if the panel display is normal), then turn on the main power supply (continue only if there are no fault alarms);

Motor identification: Implement the "motor identification" function (static/dynamic identification optional), the frequency converter automatically reads motor parameters (such as rated power, current, impedance), and optimizes control accuracy;

Core parameter settings: Configure key parameters based on load characteristics (such as control mode P100, rated speed P304, starting torque P640, acceleration/deceleration time P221/P222);

Trial operation: First, jog the motor to test the direction of rotation (to avoid equipment damage caused by reverse rotation), then gradually increase the speed to the rated value, and monitor whether the current and temperature are normal.

3. Fault diagnosis and maintenance

The manual includes a "fault code table" that details the causes and troubleshooting methods of common faults (such as F001 overcurrent, F002 overvoltage, F003 overheating), and provides maintenance recommendations:

Daily maintenance: Clean the heat dissipation channel (dust screen, heat sink) weekly, check the tightness of the wiring terminals monthly, and check the insulation resistance quarterly (main circuit to ground ≥ 1M Ω);

Regularly replace components: cooling fan (with a lifespan of about 2-3 years), electrolytic capacitor (with a lifespan of about 5-8 years, adjusted according to the ambient temperature). The manual specifies the vulnerable part models and replacement steps for different models;

Fault record: The frequency converter can store the last 20 fault information (including fault time, current/voltage/speed at the time of the fault), which can be read through the panel or communication interface to assist in locating the root cause.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923