K-WANG

Yokogawa AFV40S/AFV40D Field Control Unit (FCU)

Differentiated design: AFV40S is a single configuration unit suitable for non safety critical scenarios; AFV40D is a dual redundant configuration (with redundant power supply, processor, and communication bus), suitable for critical control circuits that require extremely high reliability, such as reactor temperature control and emergency shutdown systems.

Yokogawa AFV40S/AFV40D Field Control Unit (FCU)

Product positioning

Core role: AFV40S/AFV40D is the core component of the CENTUM VP Field Control Station (FCS), responsible for "field signal acquisition, control logic operation, equipment linkage control" functions, adapted to FIO (Field Input/Output) systems, supports remote I/O node expansion, and is widely used in process industries such as petrochemicals, power, and pharmaceuticals.

Differentiated design: AFV40S is a single configuration unit suitable for non safety critical scenarios; AFV40D is a dual redundant configuration (with redundant power supply, processor, and communication bus), suitable for critical control circuits that require extremely high reliability, such as reactor temperature control and emergency shutdown systems.

Core technical specifications

(1) General basic parameters

Power outage data protection

The main memory is equipped with battery backup, with a maximum power-off protection time of 72 hours and a battery charging time of at least 48 hours, ensuring that control programs and configuration parameters are not lost after power failure and do not need to be reloaded after re powering on.

READY contact output: 3 terminals (NC normally closed, NO normally open, C common terminal), switch contact state in case of FCU fault (such as NC opening and NO closing in case of fault), contact rated parameters: maximum 250V AC/30V DC voltage, 2A current, 125VA power, can be connected to external alarm or monitoring equipment.

communication interface

Vnet/IP interface: Dual redundancy design (AFV40S can provide single/dual power supply, AFV40D requires dual redundancy), used for communication with the operator station (HIS) and other control units of the CENTUM VP system, in compliance with industrial Ethernet standards, ensuring reliable data transmission.

ESB bus interface: AFV40S supports single configuration or dual redundancy, AFV40D enforces dual redundancy and is used to connect FIO node units (ANB10 series) or optical ESB bus relay modules (ANT401/ANT411), expanding on-site I/O access capabilities.

Environmental monitoring (HK function)

Built in HKU (House Keeping Unit) monitors the environmental status of the connected cabinet (such as temperature and fan operation status) through the HK bus or optical ESB bus, and displays the HKU operation status on the HIS (Human Machine Interface), supporting system alarm output.

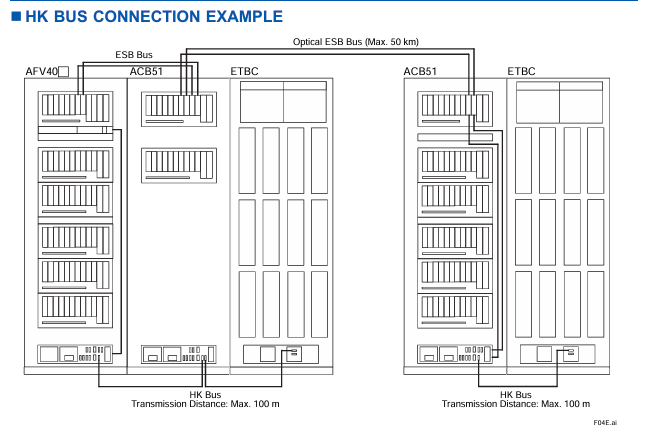

HK bus parameters: Supports connecting HKUs to cabinets such as ACUKT1/ACUKT2/ACB51/XLCabinet, with a maximum of 9 cabinets connected to a single FCU. The total length of the HK bus cable (AKBHKU) is up to 100 meters (daisy chain connection).

(2) Equipment configuration inside the cabinet

Standard equipment

Each FCU cabinet includes: 1 FCU, 1 distribution board with built-in HKU (supporting single/dual power), 2 vertical power bus units (AEPV7D, 1 front and 1 rear), up to 4 node fan units (ANFAN, 2 front and 2 rear, depending on the number of nodes), and 4 cabinet door fan units (AIP601, 2 front and 2 rear cabinet doors).

FCU module configuration

Power module: Supports PW481/PW482/PW484, dual redundant configuration requires 2 modules of the same model to ensure seamless switching in case of power failure.

Processor module: Supports CP471 (CENTUM VP R6.05 and above) or CP461 (default standard), dual redundancy configuration requires 2 modules of the same model, and only authorized engineers from Yokogawa can perform the replacement of CP461 to CP471.

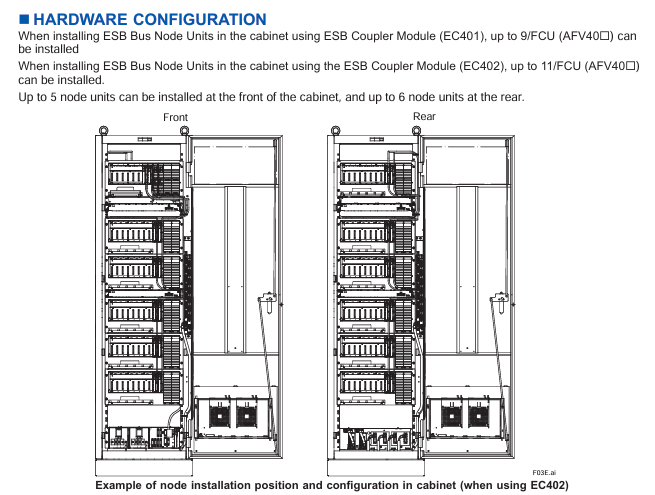

ESB bus coupler module: Supports EC401 (single/dual redundancy) or EC402 (single/dual redundancy), with two identical modules required for dual redundancy configuration to expand ESB bus nodes (EC401 supports up to 9 nodes, EC402 supports up to 11 nodes).

I/O module: Supports up to 6 non-standard I/O modules, which need to be selected according to the type of on-site signal (such as analog input, digital output) and adapted to the FIO system.

(3) Power supply and power consumption

Description of parameters AFV40S/AFV40D (maximum node configuration)

The supply voltage of 100-120V AC/220-240V AC (50/60Hz) and 24V DC should be specified through suffix codes, such as "1" representing 100-120V AC and "4" representing 24V DC

Maximum power consumption (100-120V AC) 2500VA node unit power consumption at full configuration, reduced power consumption in single node configuration

Maximum power consumption (220-240V AC) 2860VA-

Maximum power consumption (24V DC) 71A-

Power protection dual power redundancy (AFV40D mandatory, AFV40S optional) The distribution board supports dual power input and automatically switches in case of failure

(4) Mechanical and environmental parameters

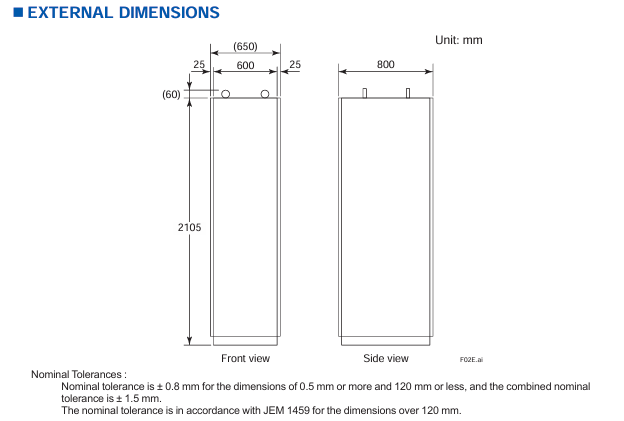

Cabinet size and weight

Dimensions (width x depth x height): approximately 600mm x 800mm x 2105mm (including cabinet), with dimensional tolerances in accordance with the JEM 1459 standard (± 0.8mm below 120mm, standard tolerances above 120mm).

Weight: The empty cabinet weighs about 240kg, and the maximum node configuration (11 node units) is about 360kg. During installation, it is necessary to ensure that the load-bearing bracket of the cabinet meets the load requirements.

environmental adaptability

Working temperature: -10 ℃~+50 ℃ (depending on the cabinet door fan and node fan for heat dissipation); Storage temperature: -20 ℃~+60 ℃.

Protection level: IP20 (only applicable to internal components of the cabinet, must be installed in a closed cabinet to avoid direct contact with dust and liquids).

Anti interference: Compliant with industrial electromagnetic compatibility (EMC) standards, refer to the CENTUM VP system overview document (GS33J01A10-01EN) for details.

Installation restrictions and configuration requirements

(1) Node unit expansion restrictions

Number and type of nodes

A single FCU can support up to 13 node units, including ESB bus node units (ANB10 series) and optical ESB bus relay module units (ANT10U), and can install up to 11 units in the cabinet (5 in the front and 6 in the back).

Remote node expansion: It needs to be connected through the optical ESB bus relay main module (ANT401/ANT411), and the relay module needs to be installed in slots 1-6 of the FCU (dual redundant configuration needs to be installed in pairs, single configuration needs to be installed in the order of slots 1, 3, and 5). The maximum transmission distance of the optical fiber cable is 50km.

Fan unit selection rules

The number of node fan units (ANFAN) should be determined based on the total number of node units in the cabinet to ensure sufficient heat dissipation and avoid module overheating

Number of required node fan units for the total number of node units (ANB10+ANT10U) in the cabinet

0-4 1

5-9 2

10 3

11 4

(2) Hardware Installation Specification

Cabinet grounding and wiring

Power wiring: M6 screw terminals are used, supporting dual power systems (main/backup power needs to be distinguished), and the input voltage should be consistent with the suffix code (such as 100-120V AC or 24V DC).

Grounding requirements: Use M8 screw terminals, with a protective grounding (PE) resistance of ≤ 4 Ω, to ensure the safety of personnel and equipment in case of leakage.

READY contact wiring: M4 screw terminals are used, and NC/NO contacts need to be selected according to the requirements of external alarm devices.

Module installation sequence

The node units inside the cabinet need to be installed in the order of "ANB10 series (ESB bus nodes) first, then ANT10U (optical ESB relay units)" to avoid communication conflicts.

The dual redundant modules (power supply, processor, ESB coupler) need to be installed in adjacent slots to ensure synchronization of redundant switching signals.

Cable restrictions

HK bus cable (AKBHKU): total length ≤ 100 meters. When connecting multiple cabinets in a daisy chain, the length of each cable segment needs to be included in the total length.

ESB bus cable (YCB301): The pre wiring inside the cabinet has been completed, but the cable between ANB10 and ANT10U needs to be connected on site, and parallel laying with power cables should be avoided (spacing ≥ 300mm) to reduce electromagnetic interference.

Model code and configuration options

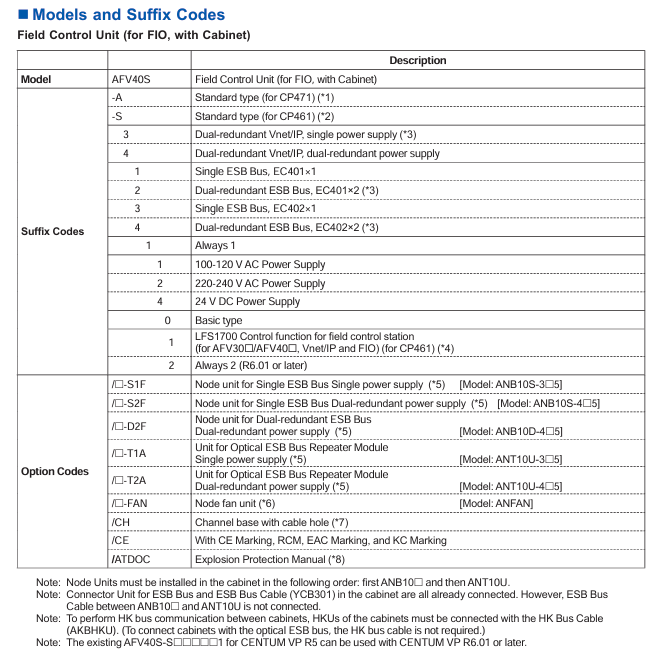

(1) AFV40S (Single Field Control Unit) Model Code

Model format: AFV40S - [suffix code 1] [suffix code 2] [suffix code 3] [suffix code 4] [suffix code 5] [suffix code 6] [suffix code 7]+option code Core suffix code meaning:

Description of optional values for suffix code bits

1 (Type) A/S A=compatible with CP471 processor (R6.05 and above); S=Compatible with CP461 processor (default)

2 (Vnet/IP) 3/4 3=dual redundant Vnet/IP+single power supply; 4=Dual redundant Vnet/IP+dual power supply

3 (ESB bus) 1/2/3/4 1=single ESB (EC401 × 1); 2=Dual redundant ESB (EC401 × 2); 3=Single ESB (EC402 × 1); 4=Dual redundant ESB (EC402 × 2)

5 (power type) 1/2/4 1=100-120V AC; 2=220-240V AC; 4=24V DC

Option code (optional as needed):

/ - S1F: Single ESB bus node unit (single power supply, model ANB10S-3 5), is the number of units (1-9/A=10/B=11).

/ - FAN: Node Fan Unit (ANFAN), is the number of fans (1-4, determined by the total number of nodes).

/CH: Channel base with cable holes (rear 300 × 40mm hole, factory equipped with filling plate), but CE/RCM/EMC/KC certification cannot be selected at the same time after selecting this option.

/ATDOC: Includes explosion-proof manual (compliant with ATEX directive, applicable to potentially explosive environments).

(2) AFV40D (Dual Redundant Field Control Unit) Model Code

Model format: AFV40D - [suffix code 1] [suffix code 2] [suffix code 3] [suffix code 4] [suffix code 5] [suffix code 6] [suffix code 7]+Option code Core difference: AFV40D requires dual redundancy configuration, suffix code 2 is fixed as "4" (dual redundant Vnet/IP+dual power supply), suffix code 3 is fixed as "2/4" (dual redundant ESB bus), and option code only supports dual redundant node units (such as/ - D2F, dual redundant ESB node units).

Software requirements and compatible systems

software license

AFV40S/AFV40D require separate purchase of software license, core dependencies:

VP6F1700 Field Control Station Control Function License (GS33J15C10-01EN): Supports the control logic operation of CP461/CP471 processors.

VP6F3100 Project I/O License (GS33J15A10-01EN): Supports I/O node expansion and signal acquisition for FIO systems.

Event Sequence Manager (SEM) compatibility

If SEM functions (event collection, timestamp recording) are required, hardware conditions must be met (such as supporting high-precision time synchronization), please refer to the document "GS33J30D10-01EN" for details.

system compatibility

Only compatible with Yokogawa CENTUM VP integrated production control system, supporting R6.01 and above versions, with CP471 processor requiring R6.05 and above versions; Seamless integration with FIO system, optical ESB bus relay module (ANT401/ANT411), HKU compatible cabinet (ACUKT1, etc.).

Attachments and related products

Standard Appendix

Factory standard: Cabinet door filter (model T9070CB, quantity 2), used to filter the dust in the cabinet inlet air, needs to be replaced regularly to ensure heat dissipation effect.

Related Products

Cabinet Connection Kit: AKT211, used for HK bus or power connection between multiple AFV40 cabinets.

Cabinet side panel: ACB2P, 2 pieces per cabinet (1 on each side) are required for cabinet side protection and need to be ordered separately.

ESB bus cable: YCB301, pre wired in the cabinet already included, additional configuration is required for the connection between ANB10 and ANT10U.

Key application precautions

Effectiveness of redundant configuration

The dual redundancy function of AFV40D must ensure that the "power supply, processor, and ESB bus module" are all of the same model and installed in designated redundancy slots, otherwise automatic fault switching cannot be achieved.

Explosion proof environment use

If used in potentially explosive environments (such as Zone 2), select the/ATDOC option code, obtain the explosion-proof manual, and ensure that the cabinet and node units comply with ATEX/IECEX certification requirements.

Maintenance and replacement

The replacement of processor modules (CP461 → CP471) is only allowed to be operated by authorized engineers from Yokogawa. User initiated replacement will result in the warranty being invalidated; The battery needs to be replaced every 3-5 years to avoid data loss during power outages.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923