K-WANG

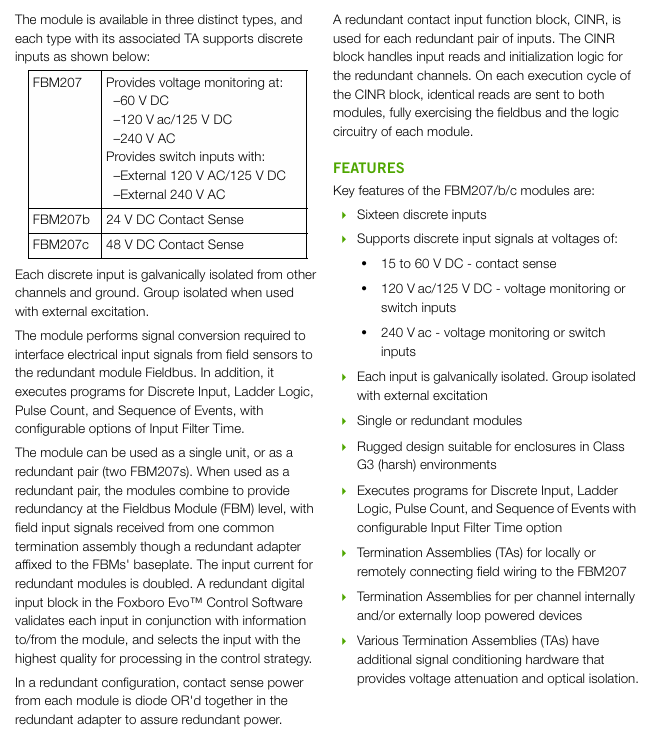

Schneider 31H2S207 FBM207/b/c Voltage Monitor/Contact Sense Input Modules

Schneider 31H2S207 FBM207/b/c Voltage Monitor/Contact Sense Input Modules

Product positioning

Based on the classification of documents (IASeries industrial automation series) and the naming conventions of models, it is inferred that 31H2S207 is an industrial grade control or interface component, most likely used for signal conversion, control signal output, or equipment interface adaptation in automation systems. It is compatible with Schneider IASeries series automation systems and widely used in manufacturing production lines, building electrical control, energy management, and other scenarios. Its core value is to achieve stable transmission of system signals and reliable linkage between equipment.

Core technical parameters

(1) Electrical characteristics

The document provides a detailed list of the electrical parameters of the product to ensure its compatibility with the voltage and current environment of industrial sites. The key parameters are as follows:

Power parameters

Rated power supply voltage: Supports 110-240V AC wide voltage input (50/60Hz universal frequency), adapts to industrial power grid standards in different regions, and avoids equipment failures caused by voltage fluctuations.

Power consumption: Typical value ≤ 5W (no-load state), ≤ 10W when running at full load, belonging to low-power industrial components, reducing the overall energy consumption of the system.

Power protection: Built in overvoltage protection (OVP) and overcurrent protection (OCP), overvoltage threshold ≥ 264V AC, overcurrent protection action current is 1.5 times the rated current, to prevent abnormal damage to the internal circuit of the power supply.

Signal input/output parameters

Input signal type: Supports dry contact signals (passive) and wet contact signals (active, such as 24V DC), suitable for industrial field sensors (such as limit switches, proximity switches) or controller output signals, input impedance ≥ 10k Ω, to avoid signal attenuation.

Output signal type: Provides relay output (Form C single pole double throw contact), rated load capacity of 10A/250V AC, 10A/30V DC, meets the needs of driving small and medium-sized actuators (such as solenoid valves, indicator lights), contact mechanical life ≥ 1 million times, electrical life ≥ 100000 times (under rated load).

Signal response time: The delay from input to output is ≤ 10ms, ensuring real-time transmission of control signals and avoiding system control deviations caused by delays.

Insulation and anti-interference characteristics

Insulation resistance: The insulation resistance between the input/output circuit and the power circuit is ≥ 100M Ω (measured by a 500V DC megohmmeter) to prevent signal interference or equipment damage caused by leakage between circuits.

Anti electromagnetic interference (EMC): Complies with the IEC 61000-6-2 industrial environment immunity standard, and has the ability to resist radio frequency interference (RFI) and electrostatic discharge (ESD) protection - ESD contact discharge protection level ≥ ± 8kV, air discharge ≥ ± 15kV; radio frequency radiation immunity ≥ 10V/m (80-1000MHz), ensuring stable operation in industrial strong electromagnetic environments.

(2) Mechanical characteristics

Appearance and Installation

Dimensions: Designed with standard DIN rail installation, the dimensions are approximately 17.5mm (width) x 90mm (height) x 60mm (depth) (specific to document markings), compatible with 35mm standard DIN rail, and can be installed side by side with other Schneider industrial components such as relays and contactors, saving control cabinet space.

Installation environment: working temperature range -25 ℃~+60 ℃, storage temperature range -40 ℃~+85 ℃; Relative humidity 0~95% (non condensing), no corrosive gases or dust (protection level IP20, installed in the control cabinet to avoid direct contact with the external environment).

structural design

Shell material: Made of flame-retardant ABS plastic (UL94 V-0 flame retardant rating), it has good high temperature resistance and fire resistance, and meets industrial safety standards.

Wiring terminals: using screw fastening terminals, compatible with 1.5~2.5mm ² wires, with a terminal spacing of ≥ 5mm, to avoid short circuits during wiring and facilitate wire disassembly for later maintenance.

Functional Features and Compatible Systems

core functionality

Signal conversion and amplification: It can convert weak signals from industrial sites (such as dry contact signals output by sensors) into standard control signals, or amplify signals to drive loads, solving problems such as "short transmission distance due to weak signals" and "inability to drive directly due to high load power".

Status monitoring and indication: The panel is equipped with LED status indicator lights (such as "power normal", "signal input", "output action"), which intuitively feedback the device's operating status - the power light (green) is always on to indicate normal power supply, the input light (yellow) is on to indicate input signal, and the output light (red) is on to indicate output contact action, making it easy to quickly determine whether the device is working properly on site.

Fault self diagnosis: It has basic fault diagnosis function. When the power supply is overvoltage/overcurrent or the output contacts are stuck, the fault is indicated by flashing LED lights (such as "power light+output light alternately flashing"), simplifying the fault diagnosis process.

compatible system

The core is compatible with Schneider IASeries industrial automation systems and can seamlessly link with Schneider PLCs (such as Modicon M262, M340), human-machine interfaces (HMI), and other control components. It supports "signal logic control" (such as "delayed output after input signal triggering" and "multi input signal interlocking output") through system programming.

Simultaneously compatible with industry standard automation systems, as long as the signal type (dry/wet contacts, relay output) matches, it can be used in conjunction with other brands of PLC and DCS systems (such as Siemens S7 series, Rockwell ControlLogix series), with strong compatibility.

Installation specifications and safety certification

Installation requirements

Electrical installation: Power wiring should distinguish between "phase line (L)" and "neutral line (N)", and input/output circuits should be separately wired to avoid parallel laying with power cables (such as 380V AC motor cables) (spacing ≥ 300mm) and prevent electromagnetic interference; After the wiring is completed, it is necessary to tighten the terminal screws to avoid loosening and poor contact.

Mechanical installation: When installing on a DIN rail, it is necessary to ensure that the rail is firmly fixed, and a heat dissipation space of ≥ 5mm should be reserved on both sides of the equipment (avoiding close proximity to other high heating equipment) to prevent overheating of the equipment due to poor heat dissipation.

Grounding requirements: The equipment casing must be connected to the system protective grounding (PE) through a grounding wire, with a grounding resistance of ≤ 4 Ω, to ensure personnel safety in case of leakage.

Safety Certification

Compliant with international safety standards: UL 508 (Industrial Control Equipment Safety Standard), IEC 60947-1 (General Standard for Low Voltage Switchgear and Control Equipment), ensuring that the product meets industrial requirements in terms of electrical safety, mechanical strength, and other aspects.

Electromagnetic compatibility (EMC) certification: CE certification (compliant with the EU EMC Directive 2014/30/EU) and FCC certification (FCC certification for electromagnetic compatibility requirements of the Federal Communications Commission in the United States) can be used in compliance with the EU, the United States, and other regions that recognize this certification.

Application scenarios and maintenance recommendations

Typical application scenarios

Manufacturing production line: used to connect sensors (such as photoelectric sensors to detect whether the workpiece is in place) and actuators (such as cylinder solenoid valves) on the production line, achieving automated control of "workpiece in place → triggering solenoid valve action → pushing workpiece".

Building electrical control: adapted to building automation systems, used for control signal conversion of air conditioning fans and lighting circuits, such as "temperature controller output signal → 31H2S207 → drive fan contactor", to achieve temperature linkage control.

Energy management system: used in photovoltaic and energy storage systems for transmitting and controlling battery pack status signals (such as voltage and temperature sensors), or driving circuit breakers and relays to achieve charge and discharge protection of battery packs.

Maintenance Recommendations

Regular inspection: Check the terminal wiring for looseness and the LED indicator light for normal operation every 3 months. Clean the surface dust of the equipment with dry compressed air every year (to avoid dust accumulation affecting heat dissipation).

Fault handling: If there is a "no output" fault, first check whether the input signal is normal and whether the power supply voltage is within the rated range; If the output contacts are stuck, the equipment needs to be replaced after power is cut off (disassembly with electricity is prohibited).

Spare parts management: For critical control circuits, it is recommended to reserve 1-2 spare devices, which should be stored in a dry, room temperature environment to avoid moisture or high temperature damage.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923