K-WANG

Yokogawa AQ6361 Optical Spectrum Analyzer

Yokogawa AQ6361 Optical Spectrum Analyzer

Functional positioning

The AQ6361 optical spectrum analyzer can achieve high-speed measurement of optical characteristics of devices such as laser diodes (LDs), light emitting diodes (LEDs), and optical amplifiers. The manual focuses on the "entry-level" operation of the equipment, covering handling precautions, installation steps, basic operations, and core specifications.

Open box verification and device model

(1) Open box inspection content

After opening the box, the following items need to be checked. If there are any discrepancies in model, missing parts, or damaged appearance, please contact the Yokogawa distributor:

Host and identification: Confirm that the model and suffix on the back nameplate of the AQ6361 host are consistent with the order, and record the instrument number (to be provided when contacting the distributor).

Standard attachments:

|Item Name | Model/Part Number | Quantity | Description|

|Power cord | Determine based on suffix code (such as - D corresponding to UL/CSA standards) | 1 | Whether it is included depends on the suffix code and must comply with the standards of the region of use|

|Rubber pad | A9088ZM | 1 | Used to fix equipment and prevent sliding|

|NA Conversion Adapter | 735385-001 | 1 | Only available with/NAC option, matching manual is IM735385-01Z2|

|Printed manual | IM AQ6361-02EN, etc. | 1 each | Includes introductory guide, download instructions, region specific documents, etc|

|Global Contact Information Table | PIM 113-01Z2 | 1 | Yokogawa Global Office Contact Information|

Optional attachments (to be purchased separately):

|Attachment Name | Model | Specification|

|AQ9447 connector adapter | AQ9447-FC/AQ9447-SC | FC/SC interface, used for optical input|

|AQ9441 connector adapter | AQ9441-FC/AQ9441-SC | FC/SC interface, used for calibrating light source output|

|NA conversion adapter | 735385-001 | FC interface, suitable for GI 50/GI 62.5 fiber optic|

(2) Interpretation of Model and Suffix Codes

The model suffix code of AQ6361 determines the equipment specifications, and the core code meaning is as follows:

Category suffix code description

Performance Specifications -10 Standard Models -20 High Performance Models

Wavelength Range SW Standard Wavelength Range EW Extended Wavelength Range

Built in light source - L1 with wavelength reference light source - L0 without built-in light source

GP-IB interface - N01 without GP-IB interface - C01 with GP-IB interface

Power cord standard - D UL/CSA standard (125V) - F VDE/Korean standard (250V), etc

Optional accessories/FC with AQ9447 (FC) connector adapter/SC with AQ9447 (SC) connector adapter, etc

Safety regulations and installation requirements

(1) Core Security Warning

Electrical safety:

The equipment is an IEC Class I safety device and must be connected to a protective grounding. The power cord must use a grounded three core wire and the voltage must match the rated value of the equipment (90-264VAC, 50/60Hz);

Do not plug or unplug connectors when the power is turned on, and do not cut off internal/external grounding wires to avoid electric shock or equipment damage.

Laser safety (including L1 built-in light source model):

The equipment is an IEC 60825-1:2014 Class 1 laser product with a built-in reference light source (wavelength 1.53 μ m, output power 0.04mW). Infrared light is continuously emitted from the optical output connector, and direct viewing is strictly prohibited as it may cause visual impairment;

Avoid direct laser irradiation on the human body, especially the eyes, during measurement.

Environmental safety:

Prohibited from use in flammable and explosive environments, rainy or humid places;

The equipment is a Class A device used in industrial environments and may cause radio interference when used in residential areas. Users need to solve the interference problem themselves.

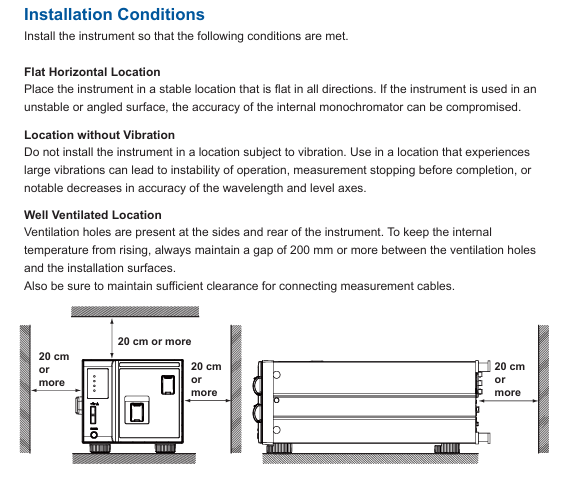

(2) Installation conditions

Physical environment:

The installation position should be horizontally stable to avoid vibration (vibration may cause a decrease in monochromator accuracy and measurement interruption);

There are ventilation holes on the side and back of the equipment, and the distance between the ventilation holes and surrounding objects should be kept at least 200mm to prevent internal overheating;

Environmental temperature: 5-35 ℃, humidity: 20% -80% RH (non condensing), avoid direct sunlight, near heat sources, and dust/corrosive gas environments.

Rack installation (requires separate purchase of rack kit):

|Kit Name | Model | Specification|

|EIA Single Installation Rack Kit | 751533-E4 | Suitable for EIA Standard Rack|

|JIS Single Installation Rack Kit | 751533-J4 | Suitable for JIS standard racks, etc|

During installation, it is necessary to remove the handles on both sides of the device and the bottom support feet to ensure that there is a reserved space of ≥ 10cm around the rack for heat dissipation, and the bottom support does not block the ventilation holes.

Equipment operation: from configuration to measurement

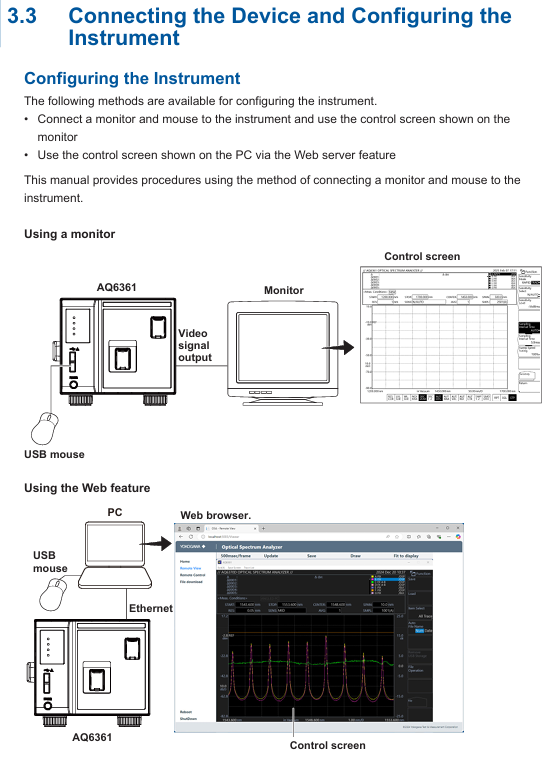

(1) Hardware connection and software configuration

Core hardware connection:

Optical interface connection: Optical input and calibration output need to be connected to optical fibers through corresponding connector adapters (such as AQ9447, AQ9441), and only FC/SC type optical connectors are supported;

External device connection: PC connects devices through Ethernet/USB, monitor connects devices through Video OUT (XGA), mouse/keyboard connects through USB interface (supports USB HID Class 1.1 standard devices).

Software device registration and connection:

|Step | Operation Content|

|1 | Start AQ6361, enter the device connection window, click "Add" for the first connection, and select the communication method (Ethernet/USB)|

|2 | Click "Search" to search for devices, check the measuring instrument (such as AQ6361) and external devices, and click "Register" to complete the registration|

|3 | Check the target device in the registration list and click "Next" to enter the measurement and display settings window|

Key parameter configuration:

RAM data channel settings: Import symbol definition files (. a2l format) in the "Measurement Setting" window, or manually enter symbols, addresses, and data types to add RAM data channels;

Time reference synchronization: Check "Relative time" in "DAQ Setting", synchronize external devices based on the measuring instrument clock, and configure the data saving path (default: C: Users Username Documents YOKOGAWA IS8000).

(2) Startup and calibration process

Startup steps:

|Step | Operation Content|

|1. Connect the power cord, turn on the "MAIN POWER" switch on the back, and the front POWER light will turn orange|

|After waiting for a few seconds, press the "POWER" switch on the front, the light turns green, the device starts and initializes (displaying STEP 1/9 to STEP 9/9)|

|After initialization, enter the measurement interface and preheat for 1 hour before performing wavelength calibration|

Wavelength calibration (key step to ensure measurement accuracy):

Built in light source calibration (- L1 model): Connect the optical input and calibration output with 9.5/125 μ m single-mode fiber, enter "SYSTEM>Wavelength Calibration>Built in Source", click "Execute", and the calibration takes about a few minutes;

External light source calibration: Supports laser type (such as DFB-LD) or gas chamber absorption line type external light sources. After connection, set the wavelength in "External Laser/External Gas Cell" and perform calibration;

Attention: If the wavelength error exceeds ± 5nm, it is necessary to contact the Yokogawa dealer for re adjustment, as it cannot be calibrated through the built-in light source.

Resolution calibration: Use a stable single-mode laser source (output power ≥ -20dBm, linewidth ≤ 5MHz), connect it, enter "SYSTEM>Res BW Calibration", click "Execute" to complete the calibration, and the device will automatically correct the equivalent noise bandwidth after calibration.

(3) Measurement Execution and Data Management

Measurement condition setting:

Select the device in the "Device Control" panel, configure parameters such as sampling rate, trigger mode, sensitivity, and ensure that the measurement cycle of external devices (such as optical amplifiers) matches the pulse frequency of the device;

Supports three modes: "Single Sweep", "Repeat Sweep", and "Auto Sweep". Auto mode can automatically optimize measurement conditions.

Measurement operation:

|Operation | Function Description|

|Monitor Start | Start measurement (only monitors, does not record data)|

|Record Start | Start Record (Synchronize measurement and recording when monitoring is not started)|

|Record Stop | Stop recording (measurement continues)|

|Monitor Stop | Stop measurement (when recording has not stopped, synchronously stop measurement and recording)|

Data saving and loading:

The data is automatically saved in. mf4 format (including waveform and RAM data), and the default path can be modified in "DAQ Setting";

When loading data, the software opens the. mf4 file or loads the. wdf (waveform) and. mdf (RAM data) files offline, and the software automatically aligns the timeline.

Maintenance and troubleshooting

(1) Daily maintenance

Cleaning requirements:

Equipment casing: Wipe with a clean dry cloth after power failure, and prohibit the use of volatile chemicals (to prevent fading and deformation);

Optical interface: Clean the end face of the optical connector with a cotton swab dipped in pure alcohol to ensure that there is no dust (dust may affect optical performance and even damage the monochromator).

Regular inspection:

|Check project | cycle | operation content|

|Wavelength accuracy check | Regular | Use a light source with known wavelength accuracy (such as a gas laser) to measure the spectrum and confirm that the center wavelength error of THRESH 3dB is within the specified range|

|Level accuracy inspection | Regular | Using a 1310nm/1550nm light source, compare the peak level measured by the equipment with the reading of the optical power meter, and ensure that the error meets the specifications|

|Firmware Update | On Demand | Download the latest firmware from Yokogawa's official website and update via USB or Ethernet (power off is prohibited during update to avoid device failure to start)|

(2) Fault handling and warning information

Common faults and countermeasures:

|Fault phenomenon | Possible causes | Response measures|

|No response upon startup | Power cord not connected properly, power voltage mismatch | Check power cord connection, confirm voltage is within the range of 90-264VAC|

|Abnormal measurement data | Optical interface contamination, wavelength calibration not performed | Clean optical interface, wavelength calibration performed|

|Communication failure | Loose USB/Ethernet connection, incorrect IP address | Reconnect the cable and check the IP address (default 192.168.1.100)|

Warning message interpretation: Chapter 5.7 of the manual provides a detailed list of 380+warning messages, with the core categories as follows:

|Warning type | Scope | Example and reason|

|Warning after function execution | 1-49 | 'Unsuitable resolution' (resolution setting does not match span/sample size, which may result in incomplete data extraction)|

|Function unable to execute warning | 50-199 | "USB storage not found" (USB storage device not inserted)|

|Hardware malfunction warning | 200-299 | "Fan motor stopped" (the fan stops running and automatically shuts down after 10 seconds, please contact maintenance)|

Core technical parameters

The key specifications of AQ6361 vary depending on the model (Standard Type -10/High Performance Type -20) and wavelength range (- SW/- EW), with the following core parameters:

Parameter Category Standard Type (-10) High Performance Type (-20)

Wavelength range SW: 1200-1700nm; -EW: 700-1700nm same standard type

Wavelength accuracy - SW: ± 0.02nm (1520-1580nm), ± 0.04nm (1580-1620nm) - SW: ± 0.02nm (1450-1620nm)

Wavelength resolution of 0.05, 0.1, 0.2, 0.5, 1, 2nm 0.03, 0.05, 0.1, 0.2, 0.5, 1, 2nm

Level sensitivity TRAD mode: -80dBm (1300-1620nm, HIGH2); RAPID mode: -73dBm (1300-1620nm, RAPID6) same standard type

Maximum input power+20dBm (single channel),+25dBm (total input power) same as standard type

Scanning time TRAD mode (NORM-AUTO): 0.2s (span ≤ 100nm, sample size 1001) Same as standard type

Suitable for single-mode (SM: 9.5/125 μ m) and multi-mode (GI: 50/62.5 μ m) equivalent standard types of optical fibers

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923