K-WANG

Tektronix AWG2021 250 MHz Arbitrary Waveform Generator

Tektronix AWG2021 250 MHz Arbitrary Waveform Generator

Basic Information and Security Standards

Product positioning: 250 MHz high-precision arbitrary waveform generator, specializing in laboratory precision testing (such as benchmark signal simulation) and industrial production line screening (such as component parameter verification), supporting custom waveform and standard function waveform generation.

Safety regulations

Specific requirements for safety categories

Overvoltage Category CAT III 1000V, CAT IV 600V Suitable Distribution System (CAT III) and Low Voltage Grid (CAT IV) Scenarios

Terminal rated value "V Ω" terminal maximum 1000V DC/AC; Terminal A has a maximum of 10A DC/AC (continuous) and 20A (30 second pulse). It is prohibited to input voltage beyond the range to avoid device damage

Operating environment working temperature+10 ℃ -+40 ℃, humidity 20% -80% (no condensation); Storage temperature -40 ℃ -+70 ℃. Exceeding this range may result in decreased testing accuracy or hardware failure

Grounding requirements require grounding through the power line grounding conductor to avoid the risk of electric shock caused by leakage

Operation Guide: Basic Process and Panel Control

1. Power on/off and self check

Startup process

Environmental inspection: Ensure good ventilation (leave 15.2cm space on the left and right sides, 7.6cm space on the top/rear), and unobstructed heat dissipation holes.

Power connection: Select the corresponding power cord according to the region (such as North America 125V, Europe 230V, refer to Table 1-1), and connect the Rear panel power interface.

Starting power supply:

Press the 'PRINCIPAL POWER SWITCH' button on the Rear panel to power on the standby circuit.

Press the "ON/STBY" button on the front panel to start the instrument and perform a self-test (approximately 3 seconds).

Self check result:

No error: Display "Pass" and enter the SETUP menu.

Error: Display "Fail"+error code (such as "Uncal" requiring UTILITY menu calibration). You can press any key to exit and enter the menu, but the waveform output may not be reliable.

Shutdown process

Press the "ON/STBY" button on the front panel to cut off the power supply to the main circuit.

When not in use for a long time, turn off the 'PRINCIPAL POWER SWITCH' on the Rear panel and unplug the power cord.

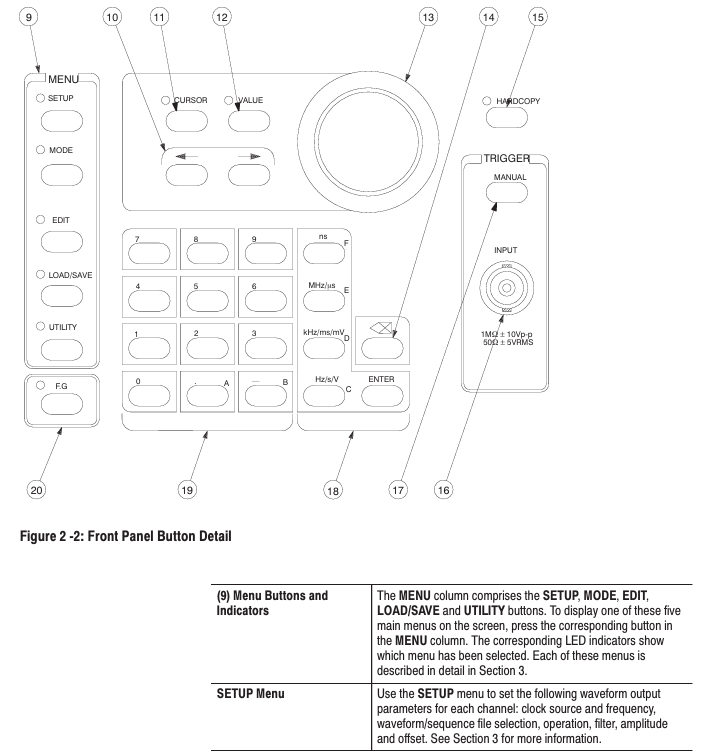

2. Key components of the front-end panel

Specific functional operation examples for component categories

MEAS key in function selection area: switch measurement function; F. G key: Switch to function generator mode and press F. G key to enter standard waveform settings such as sine/triangle/square wave

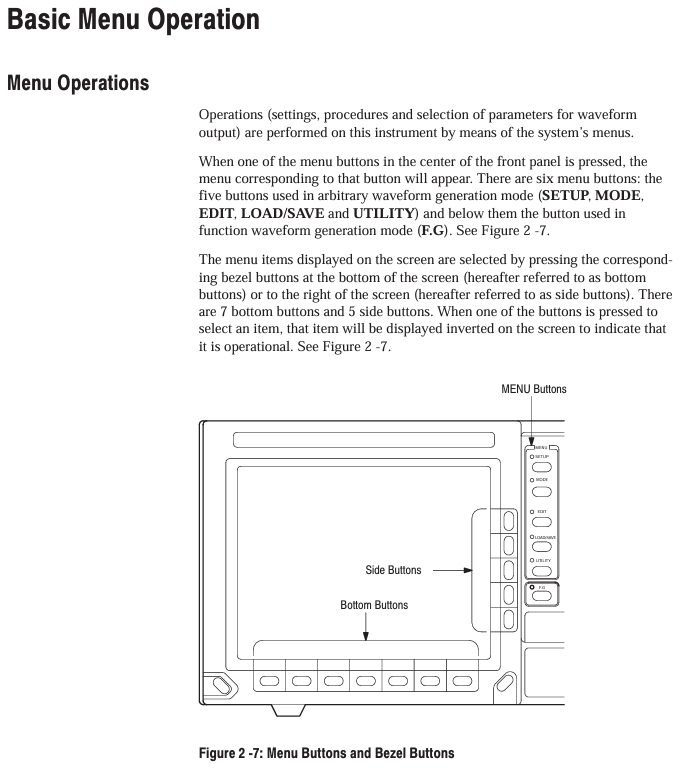

Menu Control Area MENU Column: SETUP (Parameter Configuration), MODE (Run Mode), EDIT (Editor), LOAD/SAVE (File Management), UTILITY (System Settings) Press the EDIT key to enter the initial menu for file editing

Universal knobs in the data operation area: adjust values/select files; Numerical keys (0-9/.+-): input parameters; Unit key (ns/MHz, etc.): Enter the "1"+"MHz" key to specify the unit and set the clock frequency to 1 MHz

Trigger control area TRIGGER INPUT: external trigger input (maximum ± 10 V ₚ₋ₚ); MANUAL key: Manually triggered. In Triggered mode, press the MANUAL key to trigger waveform output once

Output control area CH1/CH2 ON/OFF keys: switch channel output; SYNC/MARK output interface: Sync/Mark signal output. Press the CH1 ON/OFF button, and the LED will light up to indicate that the CH1 waveform output is turned on

Core functional module: Editor and menu configuration

1. Four core editors (EDIT menu)

(1) Waveform Editor (. WFM file)

Function: Create/edit waveform data, supports 3 display formats:

Graphic display: Visualize waveforms, support point drawing, smoothing (spline/linear interpolation), arithmetic operations (absolute value/integral/derivative).

Timing display: Display timing according to data bits (DATA 11-DATA 0), supporting the setting of - pattern (such as NRZ/NRZI encoding).

Table display: Display each point data in binary/hexadecimal/real form, supporting direct editing of numerical values.

Key operations: Select the editing area (left and right vertical cursor), perform cutting/copying/pasting, or insert other waveform files.

(2) Equation Editor (. QU file)

Function: Generate waveforms through mathematical equations, support 100 line equations, compile and generate WFM file.

Support functions: trigonometric functions (sin/cos), exponents (exp), logarithms (log/ln), random numbers (rnd), differentials (diff), integrals (integ), etc.

Example equation: range (0,1ms) sin (2 * pi * x) (generates a single period sine wave within 0-1ms).

(3) Sequence Editor (. SEQ file)

Function: Combine multiple waveform/sequence files and set the number of repetitions for each file (1-65535 times).

Operation process: Select a file from the directory → Set the number of repetitions → Generate a sequence, support "Show Overview" preview of combined waveforms.

(4) Automatic Step Editor (. AST file)

Function: Program waveforms and output parameters (clock/amplitude/filter) step by step, switch one step per trigger, supporting 100 steps.

Features: In AutoStep mode, the SETUP menu parameters cannot be modified, and the parameters between steps can be independently set (such as Step 1 amplitude of 2V, Step 2 amplitude of 3V).

2. Extended Editor (Option 09)

Editor Type Function Key Parameters

FFT editor for frequency domain editing, supporting fast Fourier transform/inverse transform window functions: 6 types including rectangle, Hanning, and Hamming; Filtering: low-pass/high pass/band-pass/bandstop

Convolutional waveform editor supports high-speed convolution/correlation operations with a maximum of 32000 data points, where the number of result points equals the sum of two waveform points

3. Key menu configuration

(1) SETUP menu (output parameter settings)

Parameter Category Configuration Options Value Range/Description

Clock source: Internal/External; Frequency (Internal) 10.00 Hz -250.0 MHz (4-digit accuracy)

Waveform Sequence (file selection) supports selecting waveform/sequence files WFM/. SEQ file, automatically loads corresponding parameters

CH1 Operation: Normal/AM/Add/External AM AM: CH1 × CH2; Add: CH1+CH2 (1/5 CH2 weight)

Filter Through/1/5/20/50 MHz suppresses high-frequency noise, such as 50 MHz filtering, which is suitable for high-frequency waveforms

Amplitude: Vertical axis full bias voltage of 0.05 V -5 V (50 Ω load, 1 mV step)

Offset Vertical axis offset voltage -2.5 V -+2.5 V (5 mV step size)

(2) MODE menu (operating mode)

Mode name function triggering conditions

Cont (continuous mode) continuously outputs waveforms without triggering, select and run

Triggered mode outputs a waveform every time it is triggered. External trigger (rising/falling edge) or MANUAL key is used

When the gate signal is valid, output waveform external signals (high/low level) or press and hold the MANUAL key

Burst mode: After triggering, output the specified number of waveform bursts 1-65535 times, triggered externally or with the MANUAL key

Waveform Advance switches to the next waveform every time it is triggered, ignoring the number of repetitions in the sequence file and cyclically outputting in order

Press AutoStep AST file step output, with independent parameters for each step and execution of one step per trigger, supporting 100 steps

Data Management and Transmission (LOAD/SAVE menu)

1. Storage medium and capacity

Storage Type Capacity Characteristics

Internal memory (RAM) up to 400 files lost due to power failure, used for temporary editing/output

NVRAM (non-volatile memory) 512KB, up to 400 files can be saved in case of power failure, suitable for long-term storage of critical files

3.5-inch floppy disk is compatible with MS-DOS format and supports directory hierarchy. It needs to be formatted first (UTILITY menu)

2. File loading/saving operations

Load file

Press the LOAD/SAVE key → select Device → select the target media (Disk/NVRam/GPIB).

Select Load → Select 'Load All' or individual file → Confirm loading into internal memory.

Save file

Press the LOAD/SAVE key → select Device → select the target medium.

Select Save → Select "Save All" or individual file → Optional ASCII format for external analysis.

3. GPIB direct transmission

Supported devices: Tek TDS series oscilloscope, HP 54600 series oscilloscope, etc. (refer to Table 3-19).

Operation steps:

Connect AWG2021 to the source device using GPIB cable.

Select Device → GPIB → Select Source Device (such as "Tek TDS CH1").

Select Load ->Automatically load waveform into internal memory (named as "TDSCH1. WFM").

Calibration and maintenance

1. Self calibration process

Trigger condition:

Regular: once every 90 days when the environment is stable (± 2 ℃); When the fluctuation is greater than 5 ℃, once every 30 days.

Manual: Press and hold the CAL key when turning on, or UTILITY → Calibration → Start.

Steps:

Disconnect all probes, the instrument displays "CALIBRATION...".

Internal calibration of ADC and reference source (approximately 2 minutes), complete display of "CAL PASS".

If 'CAL FAIL', check the ambient temperature (+18 ℃ -+28 ℃) and recalibrate.

2. Common troubleshooting

Possible causes and solutions for the fault phenomenon

No display/power adapter failure, fuse blown, replace with 12V/3A adapter; Check the 2A/250V fuse (Rear panel)

The waveform has no inflection point (such as the breakdown voltage test of the Zener transistor), the vertical sensitivity is insufficient, and the filter gear is improper. The vertical sensitivity is set to 1 μ A/div (leakage current measurement), and MAG X10 is turned on; Select a 50 MHz filter

GPIB transmission checksum error, loose cable, incorrect command format, replace GPIB cable (total length ≤ 20m); Confirm that the command termination symbol (EOI/LF) is consistent with the device

Appendix Key Content

Appendix A (Options and Accessories): Detailed description of hardware specifications and connection methods for options such as Option 02 (2-channel) and Option 03 (ECL output).

Appendix B (Performance Characteristics): Electrical characteristics (such as clock frequency accuracy ± 10 ppm), mechanical characteristics (weighing approximately 10kg), environmental characteristics (storage humidity 10% -90%).

Appendix C (Performance Verification): Includes testing procedures for clock frequency/amplitude accuracy/pulse response, etc., which require the use of a standard signal source and oscilloscope.

Appendix D (Sample Waveform Library): Provides formulas and parameters for preset waveforms such as Gaussian pulses, Lorentz pulses, DQPSK signals, etc.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923