K-WANG

ABB Advant Controller 31 40&50 Series controllers

Flexibility and Scalability: Supports local expansion (up to 6 binary or analog expansion modules) and remote expansion (up to 31 slave units connected via CS 31 bus), covering single machine control to distributed large-scale systems.

Multi scenario adaptation: widely used in fields such as mechanical control, water treatment, building management, greenhouse environmental regulation, etc., supporting functions such as complex logic control, sequence control, and data processing.

Communication capability: Integrate multiple communication protocols (MODBUS, ASCII, CS 31 bus), support interconnection with upper computer, HMI (such as TC50 display), frequency converter and other devices.

ABB Advant Controller 31 40&50 Series controllers

Product positioning and core features

The 40 series and 50 series of Advant Controller 31 are small and medium-sized programmable logic controllers (PLCs) suitable for industrial automation scenarios with 14 to 1000+inputs/outputs, featuring the following core features:

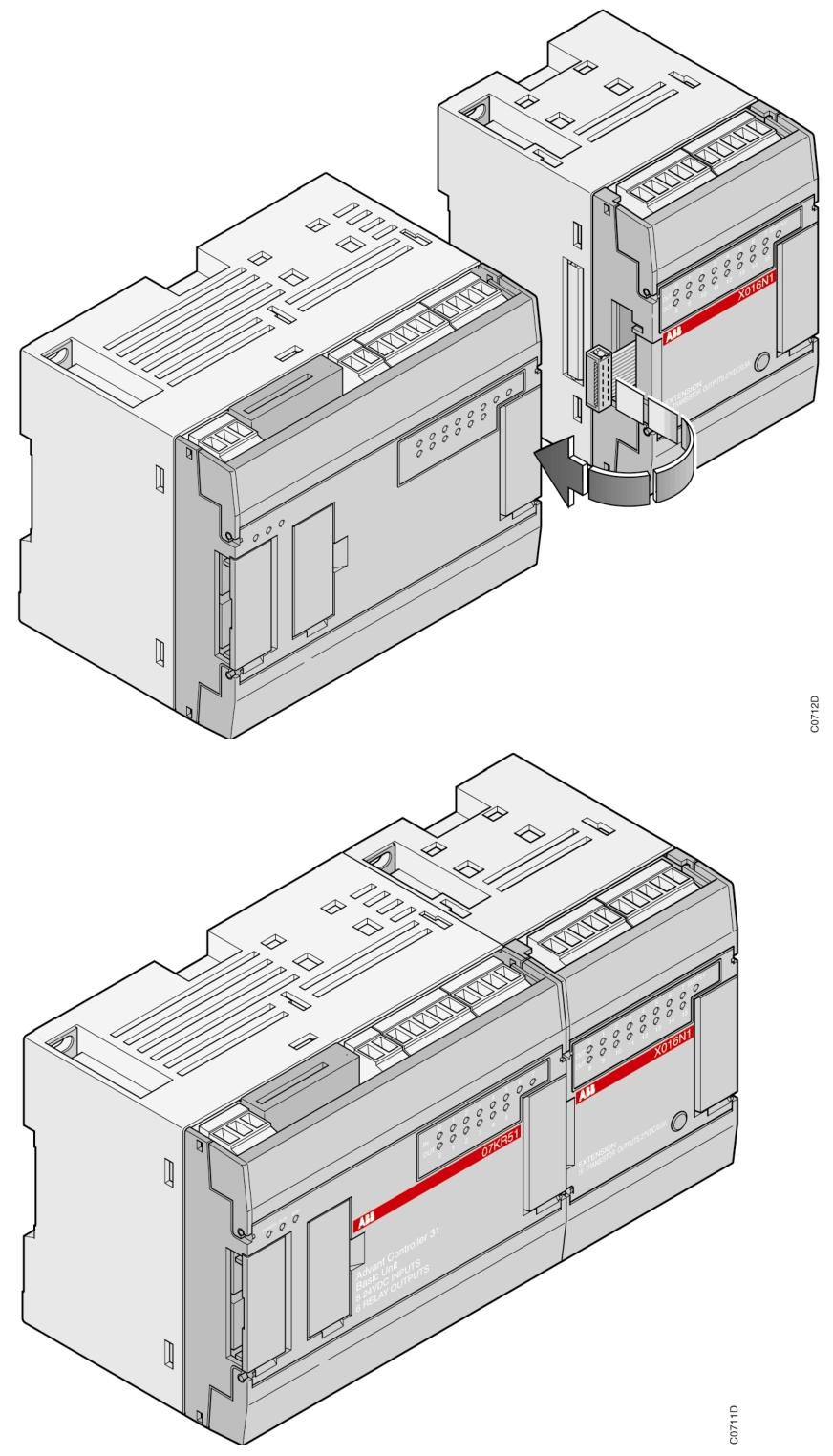

Flexibility and Scalability: Supports local expansion (up to 6 binary or analog expansion modules) and remote expansion (up to 31 slave units connected via CS 31 bus), covering single machine control to distributed large-scale systems.

Multi scenario adaptation: widely used in fields such as mechanical control, water treatment, building management, greenhouse environmental regulation, etc., supporting functions such as complex logic control, sequence control, and data processing.

Communication capability: Integrate multiple communication protocols (MODBUS, ASCII, CS 31 bus), support interconnection with upper computer, HMI (such as TC50 display), frequency converter and other devices.

Hardware composition and technical parameters

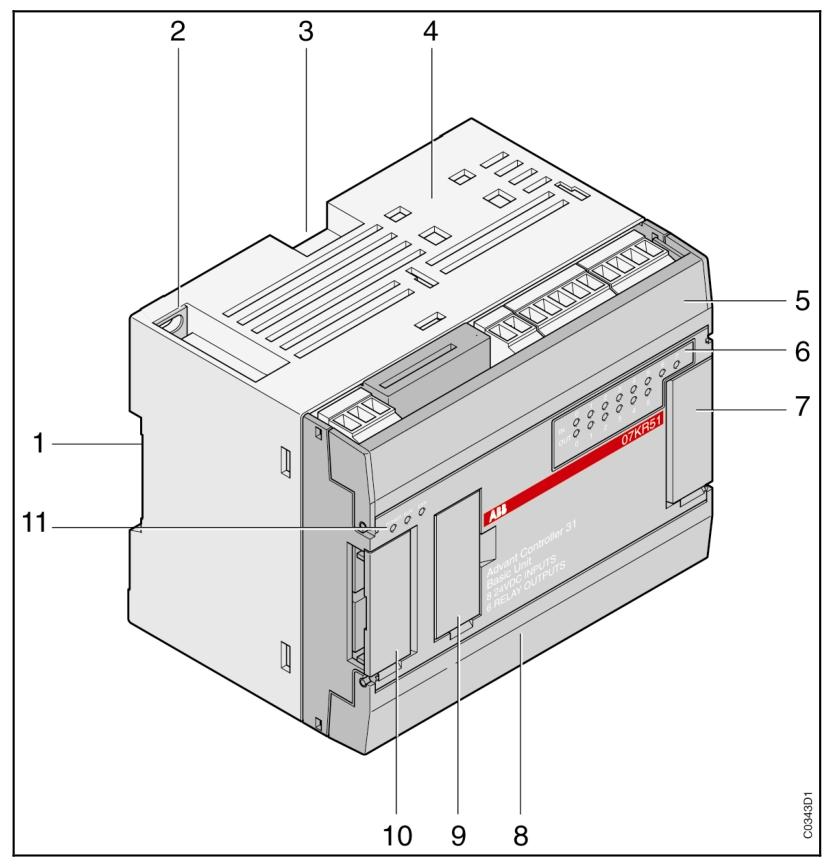

1. Central unit (40 series vs 50 series)

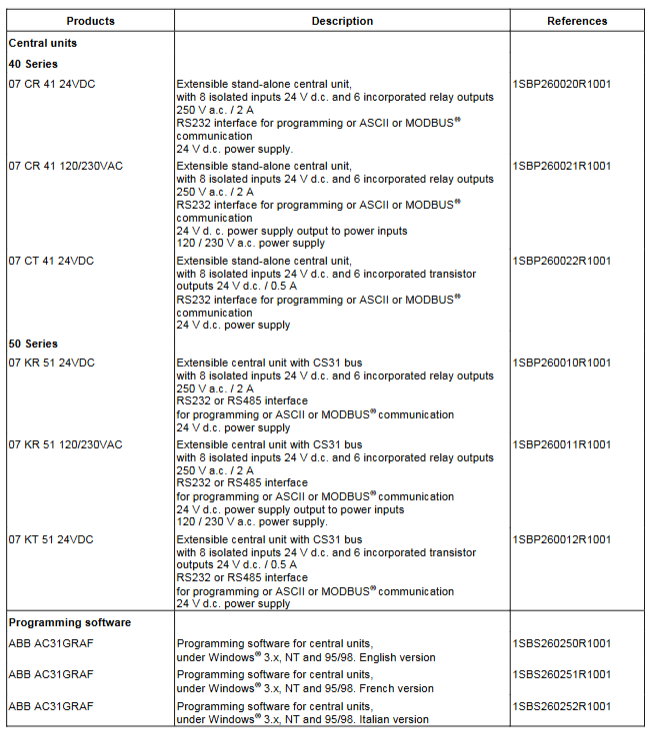

Features 40 series (such as 07 CR 41, 07 CT 41) 50 series (such as 07 KR 51, 07 KT 51)

Core configuration includes 8 isolated inputs (24V DC), 6 relay/transistor outputs, 8 isolated inputs (24V DC), and 6 relay/transistor outputs, including CS 31 bus interface

Power supply 24V DC or 120/230V AC 24V DC or 120/230V AC

Scalability up to 6 local expansion modules+31 remote slaves (CS 31 bus)

Communication interface RS232 (programming/ASCII/MODBUS) RS232/RS485 (supporting CS 31 bus master/slave mode)

Memory and Backup 17000 Word User Program Memory, RAM with Battery Backup (40 Days) Same as 40 Series, Supports Data Backup and Recovery

2. Expansion module

Binary extensions: such as XI 16 E1 (16 inputs), XO 08 R1 (8 relay outputs), XC 08 L1 (8 configurable I/O), etc., supporting the expansion of binary signal processing capabilities.

Simulation extension: such as XM 06 B5 (4 inputs+2 outputs), XE 08 B5 (8 inputs), supporting signals such as current (4-20mA), voltage (± 10V), temperature (Pt100/Pt1000), etc., with a resolution of 12 bits.

3. CS 31 bus

Physical layer: RS485 shielded twisted pair, maximum transmission distance of 500 meters (without amplifier) or 2000 meters (with 3 amplifiers).

Communication characteristics: master-slave protocol, supporting up to 31 slave stations, with a maximum transmission rate of 187.5 kbps, using CRC8 verification to ensure data reliability.

Programming and Software

1. Programming software and language

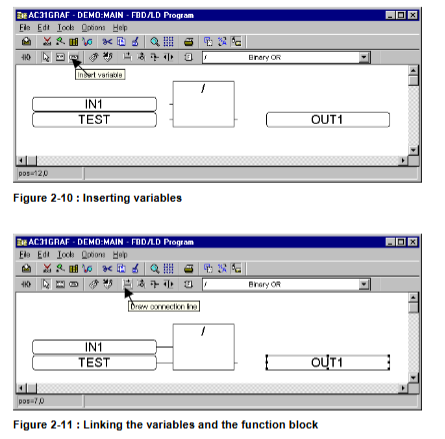

AC31GRAF: Supports Windows system, provides programming languages such as ladder diagram (LD), function block diagram (FBD), instruction list (IL), etc., and is compatible with IEC 1131-3 standard.

Core functions: variable declaration, program editing, compilation, online debugging, parameter configuration (such as cycle time, communication mode).

2. Program Structure

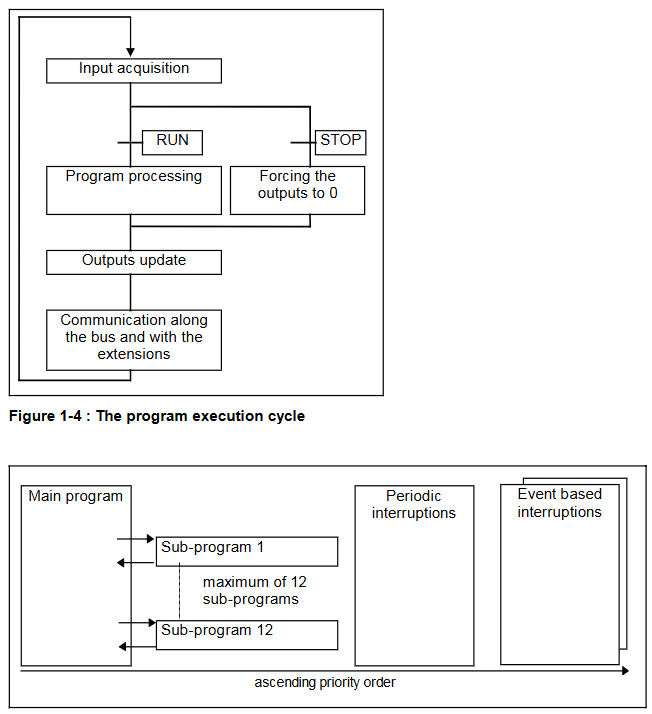

Supports the main program, up to 12 sub programs, and interrupt programs (hardware triggered or periodic), enabling complex logic and real-time response.

Built in rich functional blocks: logical operations (AND/OR), timers (TON/TOF), counters (CTU/VRZ), PID regulation, communication control (MODBUS/CS 31), etc.

Communication and Integration

Core Communication Protocol and Interface

CS 31 bus

Positioning: The core bus of distributed control adopts a master-slave architecture (RS485 standard), supporting communication between remote expansion units and central units.

Technical parameters:

Transmission medium: shielded twisted pair (AWG 24-18), maximum length of 500 meters (without amplifier) or 2000 meters (with 3 NCB/NCBR amplifiers).

Communication speed: up to 187.5 kbps, using CRC8 verification to ensure data reliability.

Connectivity: The master station can manage up to 31 slave stations (remote units, expansion modules, third-party devices such as frequency converters, etc.).

Application scenario: Suitable for workshop level distributed control, such as signal acquisition and control instruction transmission at each workstation of the production line.

MODBUS protocol

Support type: MODBUS RTU (master/slave mode), compatible with industrial standard equipment (such as HMI, PLC, frequency converter).

Interface and configuration:

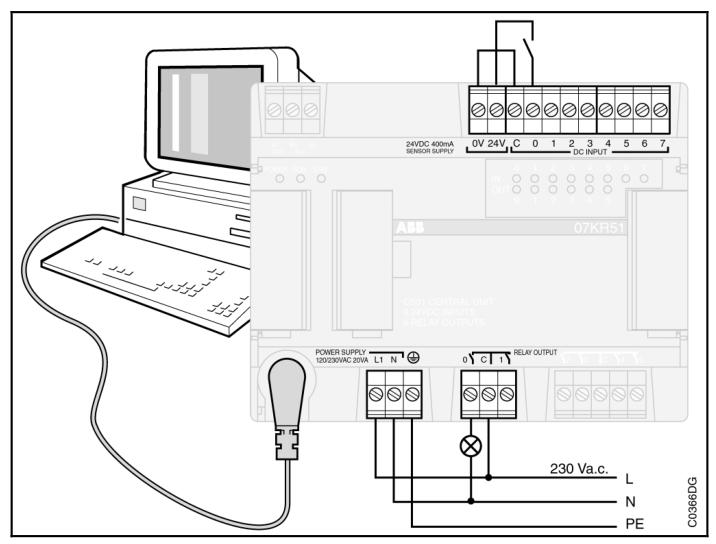

Physical interface: RS232 (40 series) or RS232/RS485 (50 series), connected through a dedicated cable (07 SK 51/53).

Communication parameters: default 9600 baud, 8 data bits, 1 stop bit, no checksum, can be adjusted through software configuration.

Function: Supports reading and writing coils (01/05 function codes) and registers (03/06 function codes), enabling data exchange with upper level computers (such as SCADA) or HMI (such as TC50 displays).

ASCII protocol

Positioning: point-to-point text communication, used for interacting with ASCII devices such as printers and terminals.

Features: Communication parameters (rate, parity, etc.) need to be configured through SINIT functions, support custom message formats, suitable for simple data printing or instruction transmission.

Integration capability and expansion methods

Native Extensions

Connect binary/analog expansion modules through dedicated interfaces, such as:

Binary extensions: XI 16 E1 (16 inputs), XO 08 R1 (8 relay outputs), supporting up to 6 modules.

Simulation extension: XM 06 B5 (4 inputs+2 outputs), XE 08 B5 (8 inputs), supports signals such as current (4-20mA), voltage (± 10V), temperature (Pt100/Pt1000), etc.

Remote integration

Connect remote units (such as ICMK 14 F1/N1) through CS 31 bus to achieve decentralized I/O acquisition and control, suitable for large equipment or long-distance scenarios (such as workshop cross area control).

Support third-party device access, such as ABB ACS series frequency converters (via NCSA-01 interface), high-speed counters (ICSF 08 D1), etc., communicating through CS 31 protocol.

HMI and upper system integration

TC50 monitor: Connected via RS232/RS485, supports 128 page display, parameter modification, alarm prompts, and is compatible with MODBUS protocol.

Programming and Monitoring: Program download and online debugging are achieved through AC31GRAF software (Windows environment), which supports real-time data interaction with PC.

Communication optimization and diagnosis

Redundancy and reliability

The CS 31 bus supports media redundancy (dual cables) and bus redundancy (dual master stations), and achieves automatic fault switching through NCBR amplifiers to reduce the risk of communication interruption.

Communication timeout detection: The master station identifies faulty slave stations through CRC checksum timeout mechanism (default 250ms), triggers alarms, and records error codes.

diagnostic function

Error classification: Divided into 4 levels (fatal error, serious error, light error, warning), the specific cause (such as bus disconnection, address conflict) is displayed through the ERR indicator light and software (AC31GRAF) of the central unit.

Communication status monitoring: Real time monitoring of communication health through variables IW 62.15 (CS 31 bus status) and MW 255. x (MODBUS watchdog).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923