K-WANG

ABB Arc Welding Robot Automation Solution

ABB Arc Welding Robot Automation Solution

Core advantages and applicable scenarios

Efficiency and economy: Robot automation can improve welding efficiency, reduce waste, and improve quality. The investment payback period for single or dual robot units can be as short as 6 months, which is not only suitable for long series production in the automotive industry, but also meets the short series or even single piece production needs of small and medium-sized enterprises.

Usability: Simplify programming and operation through specialized software tools, allowing operators to quickly program and reprogram, reducing implementation time.

One stop solution: Provide a complete arc welding package, including equipment and software, to simplify the procurement process, reduce costs, shorten delivery time, and all components are tested in the laboratory to ensure collaborative work.

Main components and functions

1. Robots

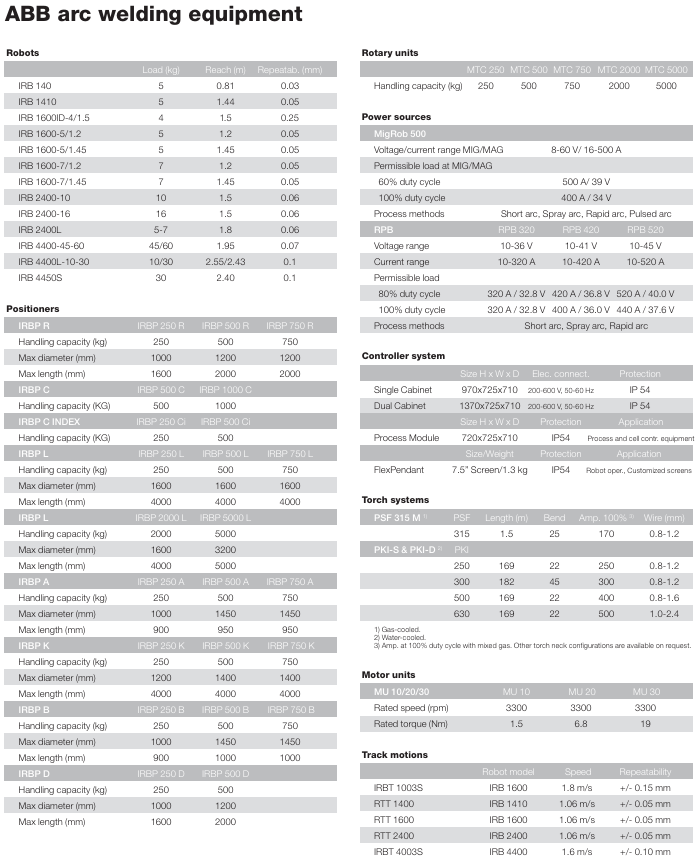

Core models: including IRB 140, IRB 1410, IRB 1600 series, IRB 2400 series, IRB 4400 series, IRB 4450S, etc., with a load range of 5-60kg, a working radius of 0.81-2.55m, and a repeat positioning accuracy of 0.03-0.1mm, suitable for different welding scenarios.

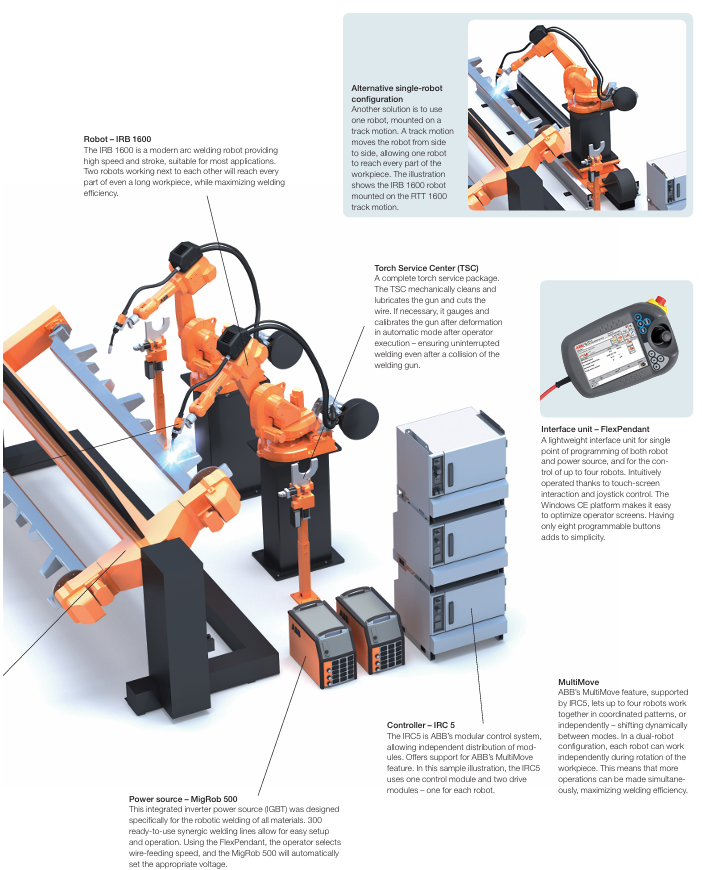

Typical applications: IRB 1600 is fast and has a large stroke, suitable for most applications. Its dual robot configuration can cover long workpieces, and when combined with orbital motion (such as RTT 1600), it can expand the operating range.

2. Power sources

MigRob 500: an integrated inverter power supply designed specifically for robot welding, supporting MIG/MAG welding, with a voltage range of 8-60V and a current of 16-500A. It includes 300 ready-made collaborative welding circuits, and the operator can automatically match the voltage after selecting the wire feeding speed.

RPB series: including RPB 320/420/520, current range 10-520A, supports short arc, spray arc, fast arc and other processes, suitable for different load requirements.

3. Positioners

Classification and Parameters: Divided by model into IRBP R/C/L/A/K/B/D series, with a load capacity of 250-5000kg, a maximum diameter of 1000-3200mm, and a maximum length of 900-5000mm, it is used to fix and rotate workpieces, making it convenient for robots to weld in all directions. For example, IRBP K 750 has a load of 750kg, can rotate axially and rotate itself, making it easy to load and unload workpieces.

4. Controller System&Interface

IRC5 controller: Modular control system, supports MultiMove function, can control up to 4 robots to work together or independently, including control module and drive module, with a protection level of IP54.

FlexPendant: Lightweight interface unit, 7.5-inch screen, supports touch operation and joystick control, programmable with 8 buttons for single point programming of robots and power supply, controlling up to 4 robots.

5. Welding gun system and auxiliary equipment

Welding gun system: including gas cooled PSF 315 M and water-cooled PKI-S/PKI-D series, with a current range of 170-500A, suitable for welding wire diameters of 0.8-2.4mm, PKI 500 D can replace Dresspack without disassembling the welding gun, saving time.

Welding Gun Service Center (TSC): Automatic cleaning and lubrication of welding guns, cutting of welding wires, automatic calibration after collision, ensuring uninterrupted welding.

Track motions: such as IRBT 1003S and RTT series, adapted to different robots, with a speed of 0.8-1.8m/s and a repeat positioning accuracy of ± 0.05-0.15mm, expanding the robot's operating range.

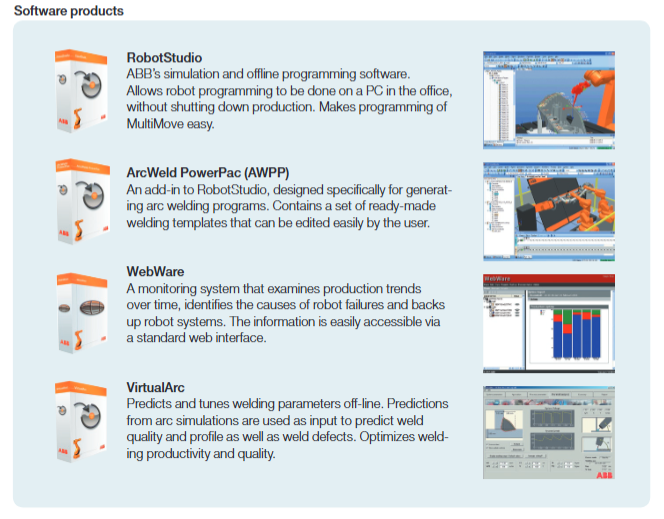

6. Software products

RobotStudio: a simulation and offline programming software that allows for robot programming to be completed in the office without affecting production, making it convenient for MultiMove programming.

ArcWeld PowerPac (AWPP): A plugin for RobotStudio designed specifically for generating arc welding programs, including ready-made welding templates for easy editing by users.

WebWare: a monitoring system that analyzes production trends, identifies fault causes, backs up robot systems, and accesses them through a web interface.

VirtualArc: Offline prediction and adjustment of welding parameters, simulating arcs to predict welding quality, contour, and defects, optimizing productivity and quality.

Typical Configuration Example

1. Dual station long workpiece welding unit (efficient mass production configuration)

Core objective: To achieve parallel loading, unloading, and welding of workpieces through a dual station design, maximizing robot utilization and suitable for welding workpieces up to 4 meters in length.

Component model/specification and function description

Robot IRB 1600 2 robots work together, with a load of 5-7kg, a working radius of 1.2-1.45m, a repeat positioning accuracy of ± 0.05mm, and high-speed welding to ensure efficiency.

The IRBP K 750 displacement machine has a load of 750kg and supports axial rotation of the workpiece (facilitating full angle welding of the robot) and self rotation (achieving dual station switching). The maximum workpiece length is 4000mm and the diameter is 1400mm.

The MigRob 500 power supply integrates IGBT inverter, supports MIG/MAG welding, with a current of 16-500A and 300 collaborative welding parameters, automatically matching wire feeding speed and voltage.

The welding gun system PKI 500 D water-cooled dual interchangeable welding gun can quickly replace Dresspack (without disassembling the welding gun), adapt to welding wire diameters of 0.8-1.6mm, and has a current of 400A at 100% load duration.

The IRC5 modular control system includes one control module and two drive modules, supports MultiMove function, and enables two robots to work independently or collaboratively.

The TSC welding gun service center automatically cleans and lubricates the welding gun, cuts the welding wire, and automatically calibrates after collision to ensure uninterrupted welding.

Workflow:

When the operator is loading and unloading workpieces at workstation A, the robot is welding at workstation B; After workstation B is completed, the positioner rotates to switch workstations, achieving seamless connection.

2. Single robot track configuration (flexible adaptation to long workpieces)

Core objective: Expand the robot's operating range through orbit, suitable for welding small and medium-sized batches of diverse long workpieces, and reduce equipment investment.

Component model/specification and function description

The IRB 1600+RTT 1600 orbital robot is installed on the track, with a track speed of 1.06m/s and a repeat positioning accuracy of ± 0.05mm. It can cover workpieces up to 6 meters long.

The RPB 520 power supply has a current of 10-520A and supports processes such as short arc and spray arc. It can output 520A at 80% load duration and is suitable for high-strength welding requirements.

The IRBP 500 L displacement machine has a load of 500kg and a maximum workpiece length of 4000mm. It rotates the workpiece horizontally to match the welding angle of the robot.

The software ArcWeld PowerPac uses the RobotStudio plugin to quickly generate welding programs, simplify parameter settings using preset templates, and shorten programming time.

Advantages: The combination of single robot and track reduces costs, and the coordinated control of track motion and robot ensures consistent welding of long workpieces.

3. Compact single workstation configuration (for small and medium batch production)

Core objective: Small footprint, suitable for scenarios with limited workshop space, balancing flexibility and economy.

Component model/specification and function description

Robot IRB 1410 has a load of 5kg and a working radius of 1.44m, suitable for small and medium-sized workpieces, with a repeat positioning accuracy of ± 0.05mm.

The MigRob 500 power supply features an integrated design that saves space and supports pulse arc welding to ensure the quality of thin-walled welding.

The displacement machine IRBP 250 R has a load of 250kg, a maximum workpiece diameter of 1000mm, and achieves multi angle welding through axial rotation.

Interface unit FlexPendant 7.5-inch touch screen+joystick, single point control of robot and power supply, simplifying operation.

Typical Configuration Example

Applicable scenarios: Small and medium-sized welding of tools, agricultural machinery, etc., optimized production rhythm and reduced downtime through WebWare monitoring system.

Common characteristics of configuration

Software and hardware collaboration: All components (such as robots, power supplies, and positioners) have been tested by ABB laboratory to ensure compatibility and reduce integration difficulty.

Flexibility: Supports offline programming (RobotStudio) and parameter optimization (VirtualArc), quickly adapting to different workpiece switching.

Reliability: The protection level of the core components reaches IP54, adapting to workshop dust and splash environments and reducing maintenance requirements.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923