K-WANG

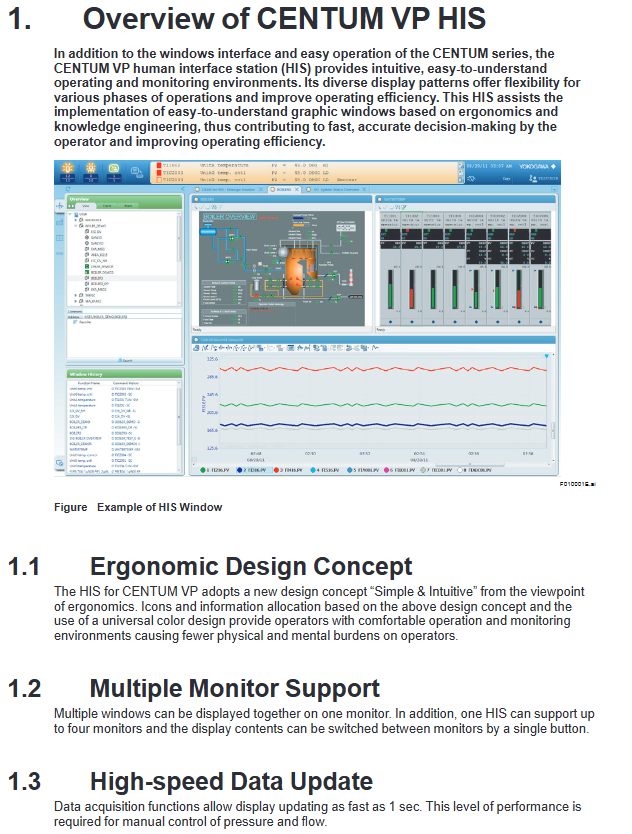

YOKOGAWA CENTUM VP System HMI (HIS)

YOKOGAWA CENTUM VP System HMI (HIS)

HIS Core Features and Hardware Composition

1. Core Features

Ergonomic design: Adopting the concept of "Simple&Intuitive", unifying icons and colors, reducing the physical and mental burden of operation

Multi monitor support: 1 HIS can connect up to 4 monitors, and supports single button switching of monitor display content

High speed data update: The data collection and update speed is as fast as 1 second, meeting the manual control requirements for pressure and flow

Operational inheritance: compatible with traditional HMI operation methods, supporting touch operation, 8 control keys, and 64 function keys

Cross system integration: can integrate alarms and events from ProSafe RS, STARDOM, PRM and other systems

2. Hardware composition

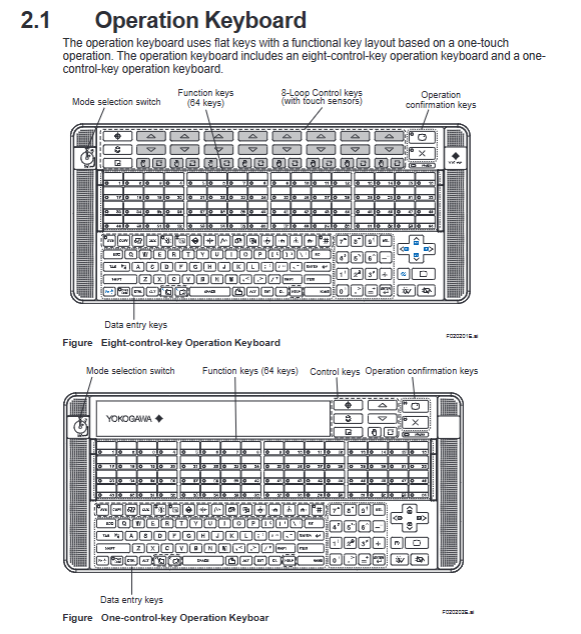

Operation keyboard: two types (8-key control type, 1-key control type), using flat key design, supporting one click operation

Core buttons: 64 function keys, mode selection switch, operation confirmation key, data input key

Special design: 8-key control type with touch sensor, suitable for high-frequency operation in industrial scenarios

Host configuration: Pre installed Microsoft Windows system, supports widescreen display, compatible with multi interface expansion

Core functions of operation and monitoring

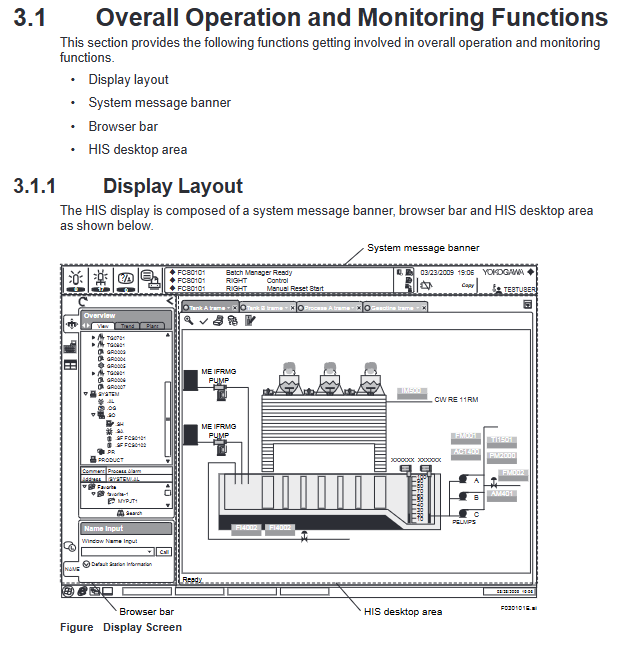

1. Overall display layout

The HIS display interface consists of three parts, with a fixed layout that does not obstruct each other:

System message bar: Permanent at the top, displaying alarm status through color/flashing, including date and time, username, and system status icon

Browser Bar: Used to call the operation monitoring window, supports tree display of factory hierarchy structure, and can minimize hiding

HIS desktop area: the core display area, including views, frames (up to 4 views/frames), container windows, and supports multi label switching

2. Core operation monitoring window

Window Type Core Function Key Parameters

Graphic view (graphic properties) visualizes the factory status with drawing objects and supports window calling to visually present device connections and operating parameters

Graphic view (controlling properties) displays the status of functional blocks on the dashboard, supporting parallel display of 8 large-sized/16 small-sized panels

Compact display of data values, function block modes, alarm status coverage PVI input, PID control, MLD manual loading and other multiple module types in panel view

Trend view time series display process data changes support simultaneous display of 8/16 pieces of data, with three split screen modes (pen split/simulated discrete split/reference mode split)

Tune view displays instrument tuning parameters and trends, supports time and data axis scaling adjustments

CAMS for HIS message monitoring integrates multiple system alarms and event support with intelligent filtering functions such as filtering, shelving, and suppression

3. Auxiliary support function

Report function: Generate daily/monthly reports based on Microsoft Excel, supporting automatic (timed/triggered) or manual printing

Imported data: settlement data (mean/total/maximum), trend data, historical messages, tag information, etc

Remote printing: supports other PCs within the network to print reports through Excel

Remote operation and monitoring: Implement remote operation and maintenance through the intranet, using the same operation window as the local HIS

Deployment requirements: The control network needs to be equipped with standard HIS to ensure reliability and real-time performance

CENTUM Desktop: A dedicated operating environment that hides Windows redundant features such as desktop icons and unrelated start menu items

HIS Utility tool: Configure the HIS operating environment, support user management, keyboard operations, security policies, CAMS parameters, and other settings

System management and security control

1. System management window

Window Name Core Usage Key Features

The system status overview displays the status of all sites and communication devices within the domain in a visual representation of normal/abnormal status through icons, and supports calling maintenance windows

The system alarm view displays hardware/communication error alarms arranged in reverse chronological order, accompanied by beeps and flashing prompts when triggered

The FCS status display view displays the hardware configuration and operational status of FCS, supports starting/closing control stations, and color coded device status

The HIS status display view shows the hardware configuration and operational status of HIS, and supports the effectiveness of switching control buses (Vnet/IP)

The HIS settings window includes 18 configuration tags (monitor, printer, trend, multi monitor, etc.) for configuring HIS operating parameters

2. Safety control system

Adopting a dual layer architecture of "CENTUM dedicated security+Windows IT security":

CENTUM dedicated security:

Permission classification: Level 3 standard permissions (S1 for monitoring only, S2 for monitoring+operation, S3 for full permissions)+Level 7 custom permissions (U1-U7)

Control granularity: Support setting operation permissions by function block and window, important operations require secondary confirmation

Tag priority: can mark important tags, ordinary tags, auxiliary tags, and differentiate alarm processing

IT security features:

Security Model: Supports traditional models, standard models (defense against network/direct attacks), and enhanced models (full threat defense)

Advanced features: password expiration (14 day advance reminder), prohibition of duplicate passwords, automatic logout (no operation timeout), user lockout (multiple password errors)

Authentication mode: Supports Windows single sign on, integrates Windows user accounts and HIS operation permissions

CAMS for HIS Alarm Management Core Function

As a core alarm management tool, following the EEMUA 191 standard, it solves the problem of alarm overflow:

1. Alarm integration and filtering

Integration scope: CENTUM VP process alarms, system alarms, operator guide messages, and external system alarms such as ProSafe RS and STARDOM

Filtering function: Basic filtering (process/system alarms), user-defined filtering, temporary filtering, supporting sorting by priority/response time

2. Intelligent alarm processing

Suspend function: Move non essential alarms to a temporary area and support manual/automatic shelving (triggered by conditions)

Suppression function: Suppress message display according to preset alarm groups/sites, reducing operation and maintenance load

Alarm setting value management: Save the engineering stage setting value as the benchmark value, support comparing the benchmark value with the current value, and overwrite updates

3. Data archiving and traceability

Support long-term data archiving, with the ability to trace alarm records through a historical viewer

Alarm details: including value-added information such as root cause analysis, role-playing suggestions, historical operation processes, etc

Applicable scenarios and industries

Applicable industries: factories in various fields such as petroleum refining, chemical industry, steel, food, electricity, etc

Core value: By visualizing operations, intelligent alarm management, and remote operation and maintenance, we aim to improve the efficiency and safety of factory operations, and support rapid decision-making

Key issues

Question 1: How does HIS's multi display support and data update feature meet the high-frequency operation requirements of industrial scenarios?

answer:

Multi monitor support: One HIS can connect up to four monitors and support single button switching of display content. It can simultaneously display various types of windows such as graphic views, trend views, alarm monitoring, etc., avoiding frequent window switching and adapting to the parallel monitoring needs of multiple parameters in industrial scenarios;

Data update performance: The data collection and display update speed is as fast as 1 second, meeting the real-time requirements of manual control of key parameters such as pressure and flow, and ensuring synchronization between operation instructions and feedback;

Hardware adaptation: The dedicated operation keyboard adopts a flat key design and one key operation logic. The 8-key control type includes a touch sensor, which reduces the fatigue of high-frequency operations and improves operation accuracy.

Question 2: As a core alarm management tool, how does CAMS for HIS solve the problem of alarm flooding in industrial scenarios?

answer:

Multi level filtering: supports basic filtering (by alarm type), user-defined filtering (by priority/response time), and temporary filtering, accurately filtering key alarms;

Intelligent processing mechanism: Reduce the number of alarms by "shelving" (temporarily hiding non essential alarms), "suppressing" (blocking redundant alarms by group/site), and "overlapping merging" (integrating duplicate alarms on the same label);

Value added information support: Alarm with root cause analysis and role-playing suggestions, helping operators quickly locate problems and avoid ineffective operations;

Set value management: Compare the benchmark alarm set value with the current value, promptly correct unreasonable settings, and reduce false alarms from the source.

Question 3: How does HIS's dual layer security control system ensure the operational safety of industrial control systems?

answer:

Fine grained control of permissions: CENTUM's dedicated security support divides the scope of operations according to user groups (such as specific FCS/windows), restricts operation permissions (monitoring/operation/engineering) according to permission levels (S1-S3+U1-U7), and requires secondary confirmation for important function block operations;

IT Security Enhancement: Implementing user account control based on Windows security features, supporting password expiration, prohibiting duplicate passwords, automatic logout, and defending against illegal login and password leakage;

Security model adaptation: Three security models (traditional/standard/enhanced) are provided, which can be selected according to the risk level of the factory. The standard model defends against network and direct attacks, while the enhanced model covers component theft and data leakage protection;

Operation traceability: User operation records are bound and archived with usernames, supporting security event traceability for easy responsibility identification and risk investigation.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923