K-WANG

YOKOGAWA built-in isolation barrier I/O module (FIO specific)

YOKOGAWA built-in isolation barrier I/O module (FIO specific)

Module classification and core technical parameters

1. Simulation module (including HART communication version)

Module Model Type Core Parameters Accuracy Current Consumption (5V DC/24V DC)

ASI133 analog input (built-in isolation gate) with 8 channels and 4-20mA input; 2/4-wire system is optional; Data update cycle 10ms ± 16 µ A 150mA/450mA

ASI133-H analog input (with HART) supports HART communication; Up to 16 devices/modules; 1200bps speed ± 16 µ A 150mA/450mA

ASI533 analog output (built-in isolation gate) with 8 channels and 4-20mA output; Load resistance 0-750 Ω (20mA) ± 48 µ A 150mA/350mA

ASI533-H analog output (with HART) supports HART communication; Multi station connection up to 5 units/channel ± 48 µ A 150mA/350mA

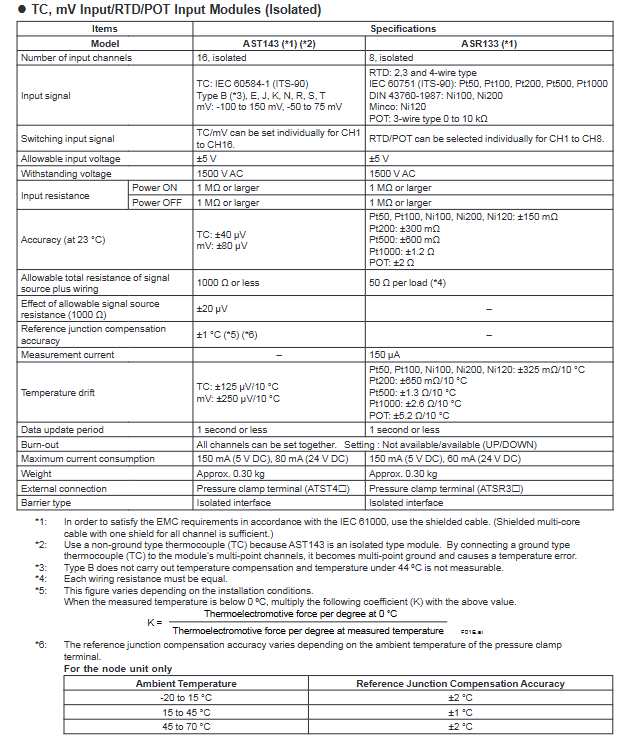

2. Temperature input module

Module Model Type Core Parameters Accuracy (23 ℃) Current Consumption (5V DC/24V DC)

AST143 TC/mV input (built-in isolation barrier) 16 channels; TC supports 8 types (IEC 60584-1); MV range -100~150mV TC: ± 40 µ V; mV: ± 80 µ V 150mA/80mA

ASR133 RTD/BOT input (built-in isolation barrier) with 8 channels; RTD supports Pt/Ni series; POT 0-10kΩ RTD:±150mΩ;POT:±2Ω 150mA / 60mA

3. Digital modules

Module model type Core parameters Response time Current consumption (5V DC/24V DC)

ASD143 digital input (with built-in isolation barrier) 16 channels; NAMUR compatible (IEC 60947-5-6) status input: 15ms 150mA/110mA

ASD533 digital output (built-in isolation barrier) with 8 channels; Output characteristics 12V (40mA), 26V (0mA) 10ms 150mA/500mA

Key characteristics and explosion-proof parameters

1. General characteristics

Electrical protection: All modules have a 1500V AC withstand voltage strength; Input resistance ≥ 1M Ω during power outage;

Environmental adaptability: working temperature -20 to 70 ℃; Compliant with ISA S71.04 G3 level anti-corrosion standard;

Redundancy support: Supports single redundancy/dual redundancy configurations, with dual redundancy installed in adjacent slots (odd+even);

Channel characteristics: module level galvanic isolation, no isolation between channels; The overall explosion-proof function of the module fails when there is a multi-channel short circuit.

2. Explosion proof parameters (ATEX/FM certification)

Module Model ATEX Parameters (Single Redundancy) FM Parameters (Single Redundancy)

ASI133 Uo=27.8V,Io=84mA,Po=584mW Voc=27.8V,Isc=84mA,Po=584mW

AST143 Uo=16.8V, Io=7mA (single channel), Po=30mW Voc=16.8V, Isc=7mA (single channel), Po=30mW

ASD143 Uo=9.8V,Io=21mA,Po=52mW Voc=9.8V,Isc=21mA,Po=52mW

ASD533 Uo=27.16V,Io=108.6mA,Po=738mW Voc=27.16V,Isc=108.6mA,Po=738mW

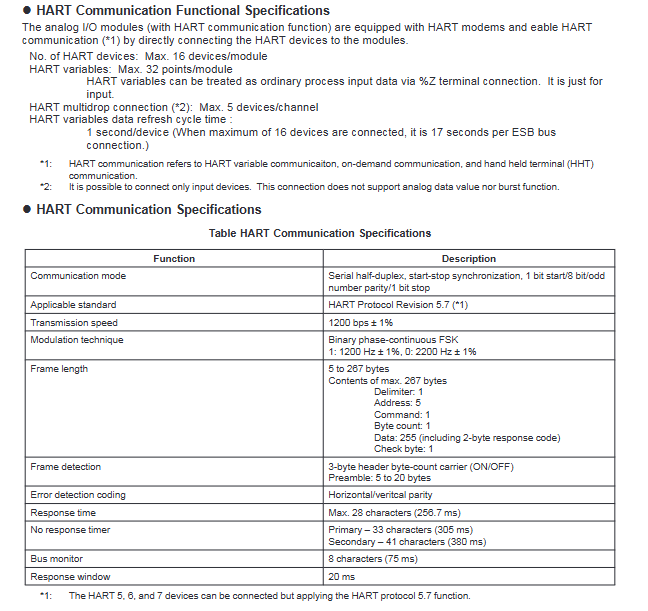

Detailed explanation of HART communication function

1. Core specifications

Communication mode: Serial half duplex, start stop synchronization (1-bit start/8-bit data/1-bit odd parity/1-bit stop);

Applicable standard: HART Protocol Revision 5.7 (compatible with HART 5/6/7 devices);

Transmission rate: 1200bps ± 1%;

Connection capability: up to 16 devices/modules, up to 5 devices/channels for multi station connection (input devices only);

Data refresh: 1 second per device (17 seconds per ESB bus connection for 16 devices).

2. System configuration

Support dual redundancy configuration: Two modules are installed in adjacent slots of the same node unit;

Data flow: FCS reads and writes analog data and HART variables through the I/O mapping area. The HART variables are connected through the% Z terminal and only support input.

Installation and compatibility requirements

1. Hardware compatibility

On site control unit (FCU): AFV30S, AFV30D (equipped with PW481-11/PW482-11/PW48284-11 power modules);

Node units: ANB10S/10D, ANB11S/11D (specific model suffix);

Connection method: pressure clamp terminal (single redundant: ATSA3S/ATSS3S, etc.); Dual redundancy: ATSA3D/ATSS3D, etc.

2. Software and Engineering Requirements

Control function: VP6F1700 on-site control station control function (applicable to AFV30 );

Engineering tool: VP6E5100 standard builder function;

EMC requirement: Shielded cables are required (one layer of shielding can be shared across all channels).

Module size and model code

1. External dimensions (unit: mm)

ASD143: Width 32.8, Height 130, Depth 94 (including protrusion 13.5);

Other modules (ASI133/533, AST143, ASR133, ASD533): Same size as ASD143;

Tolerance standard: 0.5-120mm dimensional tolerance ± 0.8mm, combination tolerance ± 1.5mm; follow JEM 1459 for dimensions greater than 120mm.

2. Model coding rules (taking ASI133 as an example)

Basic model: ASI133 (analog input, built-in isolation gate);

Suffix codes: - S (standard type), - H (with HART), 00 (fixed position);

Option codes:/SA3S0 (single redundant pressure clamp terminal),/SA3D0 (dual redundant pressure clamp terminal).

Key issues

Question 1: What is the explosion-proof adaptation scenario for the built-in isolation barrier I/O module in this series? What are the core requirements to pay attention to during installation?

answer:

Explosion proof adaptation scenario: The module can be installed in Zone 2/Division 2 environment and can connect to on-site equipment in Zone 0/1/Division 1, complying with ATEX and FM3610 certification standards;

Core installation requirements:

Hardware compatibility: Only compatible with specific models of AFV30 series FCU and ANB10/11 series node units, requiring PW481-1/PW482-11/PW482-11/PW48841-11 power modules;

Wiring requirements: Shielded cables must be used to avoid simultaneous short circuits in multiple channels (otherwise the explosion-proof function of the module will fail);

Redundant configuration: Dual redundancy should be installed in adjacent slots (odd+even), and the terminals should use dual redundancy pressure clamp terminals;

Environmental restrictions: Operating temperature -20 to 70 ℃, following ISA S71.04 G3 level anti-corrosion requirements.

Question 2: What are the core communication features of the module with HART communication function (ASI133-H/ASI533-H)? What scenarios are applicable?

answer:

Core communication characteristics:

Communication parameters: 1200bps rate, serial half duplex mode, compatible with HART Protocol Revision 5.7;

Connection capability: up to 16 devices/modules, supporting 5 devices/channels for multi station connection (input devices only);

Data processing: HART variables are connected through the% Z terminal and only support input. The data refresh cycle is 1 second per device;

Redundancy support: Can be configured with dual redundancy, consistent with the installation requirements of ordinary modules.

Applicable scenarios: In explosion-proof environments where analog signal transmission and remote monitoring of equipment are required (such as in the petroleum and chemical industries), additional parameters of on-site equipment (such as equipment status and diagnostic information) can be read through the HART protocol without the need for additional wiring.

Question 3: What are the differences in the number of channels, accuracy, and current consumption among different types of modules? How to select based on demand?

answer:

Summary of core differences:

Module type Channel number Accuracy range 24V DC Current consumption

Analog input (ASI133) 8 ± 16 µ A 450mA

Analog output (ASI533) 8 ± 48 µ A 350mA

TC/mV input (AST143) 16 ± 40~80 µ V 80mA

RTD/BOT input (ASR133) 8 ± 150m Ω~± 2 Ω 60mA

Digital input (ASD143) 16- (NAMUR compatible) 110mA

Digital output (ASD533) 8- (10ms response) 500mA

Selection principle:

Signal type: Select AST143 (multi-channel TC/mV) or ASR133 (RTD/BOT) for temperature signal; Analog selection ASI133/533; Select ASD143/533 for switch quantity;

Accuracy requirement: Select ASI133 (± 16 µ A) for high-precision analog acquisition; Select AST143 (± 40 µ V) for temperature acquisition;

Power consumption limitation: ASR133 (60mA) or AST143 (80mA) is preferred for low-power scenarios;

Expansion requirement: Remote monitoring equipment with HART ASI133-H/ASI533-H needs to be selected.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923