K-WANG

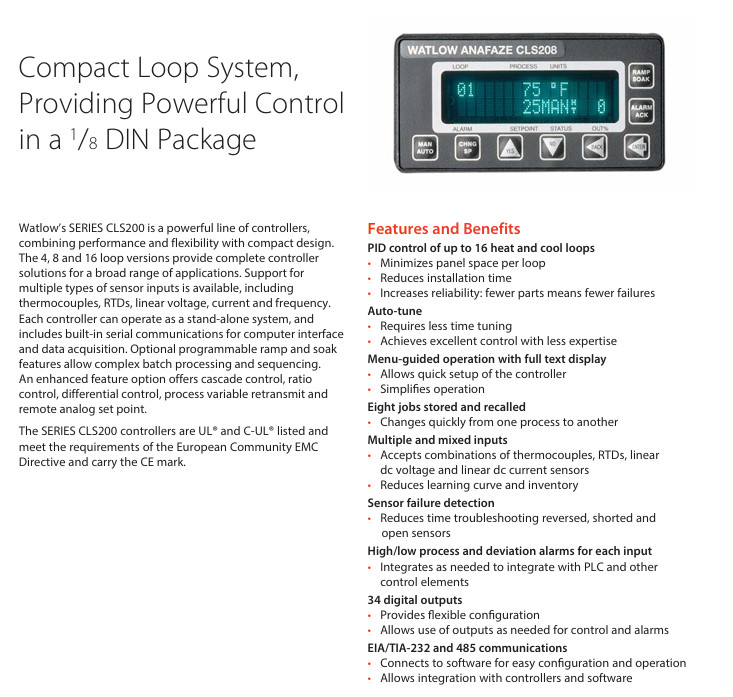

Watlow Anafaze CLS200 Series Controller

Watlow Anafaze CLS200 Series Controller

Product basic positioning and core advantages

1. Product positioning

The CLS200 series is a compact loop control system designed in a 1/8 DIN package, offering three versions: 4-loop (CLS204), 8-loop (CLS208), and 16 loop (CLS216), which can cover multi scenario temperature control requirements (such as industrial heating/cooling control, batch processing, etc.). The device supports independent operation and can also be connected to a computer system through serial communication for data acquisition and remote control, in compliance with UL standards ®、 C-UL ® Certification and EU EMC directive, with CE mark.

2. Core advantages

Advantage categories, specific characteristics, and value

Space and efficiency: Single circuit occupies less panel space, supports multi circuit integration to reduce installation time, and reduces panel layout complexity

Easy to use Auto tune function; 32 character vacuum fluorescent display screen+8-key keyboard, menu guided operation reduces debugging threshold, precise control can be achieved without professional skills; Quickly complete parameter settings

Flexibility supports thermocouples RTD、 Multiple sensor inputs such as linear voltage/current, frequency, etc; 8 homework programs are stored and called to reduce spare parts inventory and learning costs, allowing for quick switching between different process flows

Reliability sensor fault detection (open circuit, short circuit, reverse connection); 34 digital outputs (50 pin terminal board configuration) shorten troubleshooting time and flexibly adapt to control and alarm requirements

Scalability supports EIA/TIA-232/485 serial communication; Optional DAC/SDA analog output module for easy integration with PLC and upper computer, meeting the requirements of analog signal conversion (such as process variable retransmission, motor speed regulation)

Core functions and firmware options

1. Basic control functions

PID control: Supports closed-loop PID control for up to 16 heating/cooling circuits, with 1-2 control outputs per circuit (supporting on/off time ratio and distributed zero crossing triggering).

Alarm function: Each input channel is equipped with independent process alarms (high/low limit) and deviation alarms, supporting user-defined dead zone, delay time, and startup suppression. The global alarm output can be linked to the PLC, and the watchdog output indicates the controller's operating status.

Data storage: capable of storing 8 job programs, supporting quick calling and switching of processes; The controller configuration can be imported/exported through the serial port.

2. Firmware version selection

Select firmware with different functions according to application requirements, and the core differences are as follows:

Firmware type, core functions, applicable scenarios

Standard firmware includes basic closed-loop PID, automatic tuning, alarm, job storage, sensor fault detection, and conventional temperature control scenarios such as constant temperature heating and simple cooling control

Ramp and Soak firmware includes standard functions+ramp heating/insulation control, process variable retransmission for complex batch processing (such as material aging testing, food processing, requiring staged temperature control)

Enhanced firmware includes standard functions+process variable retransmission, remote simulation set points, cascade control, proportional control, differential control, high-precision linkage control scenarios (such as multi loop coupling temperature control, remote set point adjustment)

Note: The serial control and remote simulation set point functions of the enhanced firmware require 2 controller channels to be occupied; Unused control outputs can be configured for process variable retransmission (with SDAC module).

Detailed explanation of technical parameters

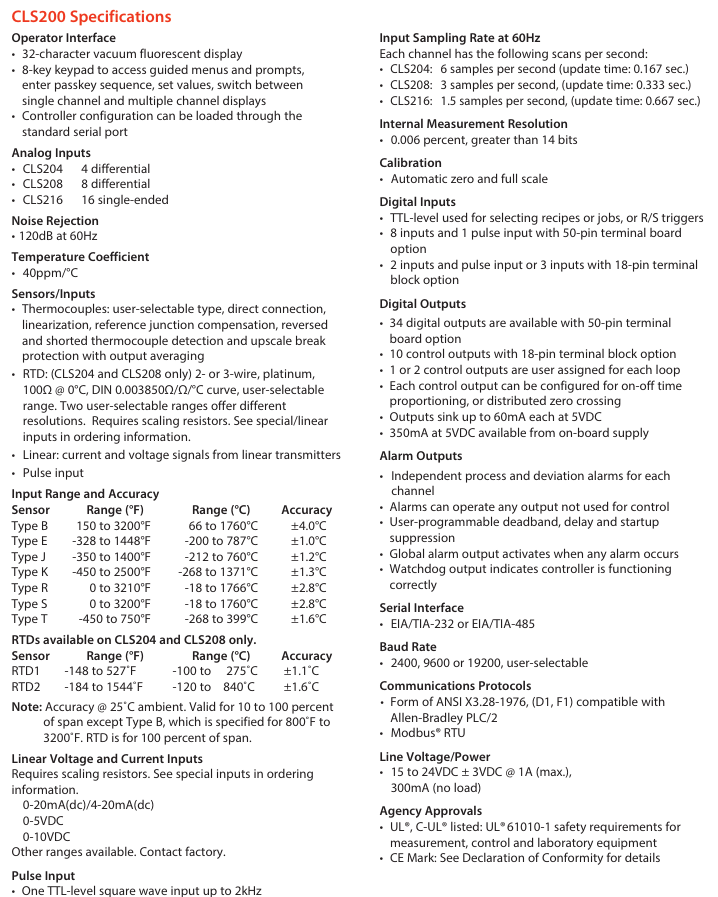

1. Input parameters

(1) Analog input and sensor support

Input type, specific specifications, accuracy (25 ℃ environment)

Thermocouples support Type B/E/J/K/R/S/T, direct connection, with cold junction compensation and linearization; Type B has a range of 66-1760 ℃, while other types have a range of -268~1371 ℃ (depending on the type) ± 1.0~4.0 ℃ (Type E has the highest accuracy and Type B has the lowest accuracy)

RTD (CLS204/208 only) 2/3 wire platinum resistance (100 Ω @ 0 ℃, DIN 0.003850 Ω/Ω/℃), divided into 2 ranges:

-RTD1: -100~275 ℃ (0.1 ℃ resolution)

-RTD2: -120~840 ℃ (1 ℃ resolution) ± 1.1 ℃ (RTD1), ± 1.6 ℃ (RTD2)

Linear input requires an external scaling resistor, supporting 0-20mA/4-20mA DC, 0-5V DC, 0-10V DC, and other ranges can be customized-

Pulse input TTL level square wave, up to 2kHz-

(2) Input performance

Noise suppression: 120dB at 60Hz; Temperature coefficient: 40ppm/℃;

Sampling rate: CLS204 (6 times/second, update time 0.167 seconds), CLS208 (3 times/second, 0.333 seconds), CLS216 (1.5 times/second, 0.667 seconds);

Measurement resolution:>14 bits (0.006% range).

2. Output parameters

Digital output: 34 outputs when configured with a 50 pin terminal board, 10 outputs when configured with an 18 pin terminal board, with a maximum sink current of 60mA (5V DC) per output. The onboard power supply provides 350mA (5V DC);

Analog output: No onboard analog output, requires optional module expansion (DAC/SDC).

3. Communication and Power Supply

Serial communication: EIA/TIA-232 or EIA/TIA-485, baud rates 2400/9600/19200 can be set, supports ANSI X3.28-1976 (compatible with Allen Bradley PLC/2), Modbus ® RTU protocol;

Power requirements: 15-24V DC ± 3V, maximum 1A (loaded), 300mA (unloaded), optional 120/240V AC to 15V DC adapter (UL) ® Class 2 certification).

Optional modules (DAC/SDC)

Used to convert the digital output of the controller into analog signals to meet specific control requirements:

Module type, functional specifications, application scenarios

DAC (Digital to Analog Converter) 1-2 distributed zero crossing trigger (DZC) outputs are converted into analog signals, each of which can be configured as 4-20mA DC, 0-5V DC, or 0-10V DC for simple analog signal conversion (such as valve opening control, ordinary speed regulation)

SDAC (Serial Digital to Analog Converter) 1 high-precision analog output (voltage/current), supporting process variable retransmission, open-loop control, motor/belt speed regulation, phase triggered SCR power control, with CE/UL ®/ C-UL ® Certification of high-precision signal requirements (such as precision instrument temperature control, remote monitoring of process variables)

Module power configuration

Power option specifications support module quantity

A has no power supply-

B 120V AC 60Hz wall mounted power supply (16V DC 300mA) with up to 10 dual DAC modules

H 120/240V AC 50/60Hz adapter (15V DC 1.2A) with up to 12 dual DAC modules

L 120/240V AC 50/60Hz adapter (5V DC 3A) with up to 10 SDAC modules

Ordering Rules and Selection Guide

1. Ordering code for the main controller (Series CLS200)

The code structure consists of 10 bits, and the key bits have the following meanings (see the document "Ordering Information" for the complete structure):

Code bit meaning optional values

② ③ Number of circuits: 04=4 circuits, 08=8 circuits, 16=16 circuits

④ Controller type (firmware) 1=standard, 3=slope insulation, 4=enhanced, C=customized

⑤ Terminal board 0=SCSI interface only, 1=18 pin terminal block (CLS204/208), 2=50 pin terminal block (including 3-foot SCSI cable)

⑥ Power adapter 0=none, 3=120/240V AC to 15V DC (UL) ® Class 2)

⑦ SCSI cable 0=none (option 0/1), 1=6-foot straight head, 2=3-foot elbow

⑧ Serial communication cable 0=none, 1=10 feet DB-9 female head/bare wire

⑨ Communication jumper 0=EIA/TIA-232, 1=EIA/TIA-485, 2=EIA/TIA-485 terminal matching

⑩ Special input 0/00=thermocouple only/-10~60mV, N/NN=current/voltage/RTD quantity (N is the quantity), XX=custom code

2. Special input selection (10 digits)

If you need to support RTD and linear current/voltage input, you need to specify a special input code:

Special input code type applicable to controllers

20 RTD1 (-100~275 ℃, 0.1 ℃ resolution) CLS204/208

21 RTD2 (-120~840 ℃, 1 ℃ resolution) CLS204/208

44 0-20mA/4-20mA DC Full Series

55 0-5V DC Full Series

56 0-10V DC Full Series

3. DAC/SDAC module ordering code

Code structure: CLSSI+special input type+start channel+end channel, for example, "CLSSI 44 01 04" represents 4-20mA input, covering 1-4 channels.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923