+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

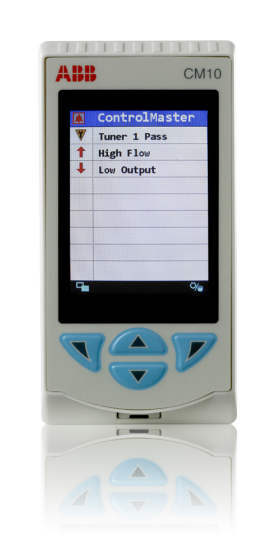

ABB ControlMaster CM10 Universal process controller, 1/8 DIN

ABB ControlMaster CM10 Universal process controller, 1/8 DIN

ABB ControlMaster CM10 Universal process controller, 1/8 DIN

Comprehensive display of process status— Crystal-clear, full-color TFT display

— User-customizable

Exceptionally easy to use

— Intuitive user interface and clear text prompts

make installation, commissioning and operation quick and

simple

Scalable to match application requirements

— Comprehensive hardware and software options

Flexible control functionality

— On / Off, time proportioning, analog PID and motorized

valve control strategies

Problem-solving capability

— Flexible functionality including math and logic providing

power to solve application requirements

Built to survive

— IP 66 and NEMA 4X environmental protection

Flexible connectivity

— Ethernet and MODBUS® communication

Overview

The ControlMaster CM10 is a flexible, 1/8 DIN, universal PID process controller. Detailed process information is presented clearly

on the CM10's full-color TFT display and an intuitive operator interface simplifies configuration and operation.

Scalable in both hardware and software functionality, a CM10 can be specified easily to meet the needs of your application

requirements. Flexible control functionality including on / off, time proportioning, analog PID, split output control and math & logic

make the CM10 suitable for a wide range of process applications.

Fully configurable via the easy-to-navigate front panel menus or PC configuration software, the CM10 can be commissioned

rapidly and then tuned via the advanced autotune functionality.

MODBUS and Ethernet communication options ensure easy integration into a control system.

Universal Process Input

— Thermocouple

— RTD

— Resistance

— mA

— V

— mV

— Frequency

— Volt-free Digital Input

— 24 V Digital Input

Transmitter Power Supply

Process Input

— Thermocouple

— mA

— V

— mV

— Volt-free Digital Input

— 24 V Digital Input

Primary Outputs

— 1 x Analog / Digital

— 1 x Relay

Additional I/O Option 1a

— 1 x Relay

Additional I/O Option 1

— 1 x Analog Output

— 2 x Digital I/O

— 3 x Relay

Communications

— Ethernet

— RS 485 MODBUS

Scalable functionality

The CM10 is scalable in terms of both hardware and software, enabling it to meet your application requirements. The basic CM10

meets the needs of a simple control loop. Additional templates and functionality can be enabled by adding a function key to the

basic model as shown in Fig. 1, while retaining previous templates and functionality. For I/O builds, see also Ordering information

on page 19.

Level Function Keys Template Functionality

Base 0 Single loop

Single loop with remote setpoint

Process alarms

Basic setpoint switching

Basic control

— Analog PID

— On / Off or time proportioning

— Auto tune

— Split output control

Standard 1 Auto / Manual station low signal selection

Auto / Manual station digital signal selection *

Analog backup station low signal selection

Analog backup station digital signal selection *

Single indicator / manual loader

Dual indicator / manual loader

Standard setpoint switching

Standard control

— Gain scheduling

— Motorized valve control †

Output tracking

Logic

Math

Custom linearizers

Delay timers

Real time alarms

Template customization

Powerful operator display

The CM10 features a full-color 5.5 cm (2.2 in.) display for

displaying detailed process information to the user. Process

details such as alarm messages and diagnostic information are

displayed clearly in full text without the need for difficult-to read scrolling displays.

Example of an operator page

Automatic selection of standard display templates immediately

makes best use of the CM10's display. Extensive

customization features then enable the displayed information

to be tailored to suit the process requirements.

Diagnostics and alarm status display

The diagnostics and alarm status display provides detailed

information on any active alarm or diagnostic condition. The

operator can see, at-a-glance, the status of any alarm

condition present within the process. Additionally, diagnostic

messages are presented clearly to the operator, enabling rapid

notification and simple diagnosis of any critical instrument

status condition.

Historical information of diagnostic messages can also be

viewed in the controller's diagnostic log.

Exceptionally easy to use

The CM10's full-text display and simple-to-navigate, pop-up

menu makes operation exceptionally easy.

A programmable soft key enables commonly used functions,

such as auto / manual selection, alarm acknowledgement and

display selection, to be accessed easily by the operator.

Flexible control functionality

The CM10 features flexible control functionality making it

suitable for a wide range of applications. Features include:

Autotune

Once initial configuration is complete, a powerful autotune

facility enables automatic calculation of the PID values

required, enabling rapid commissioning of the CM10.

Gain scheduling

The CM10's gain scheduling functionality is used for efficient

control of non-linear processes. Up to 3 different sets of PID

parameters are selected automatically from a reference signal

ensuring optimum control response, regardless of the process

status.

Split output control

The CM10 can also be configured to perform split output

control, for example, when both heating and cooling of a single

process is required.

Remote auto / manual switching

In addition to switching via the front panel, the CM10 can be

switched between automatic and manual control mode using

an external signal. When switched to manual mode via a digital

signal, the value of the control output can be preset, for

example, to open a control valve automatically during a

cleaning cycle.

External setpoint selection

The CM10's control setpoint can be selected via external

digital signals, for example, simplifying operation by selecting

different setpoints using external push buttons.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

51

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923