K-WANG

Yaskawa CP-9200SH Controller

Core advantages:

Modular structure, supporting flexible expansion;

Multi axis control capability, capable of controlling up to 224 axes;

Compatible with multiple communication protocols and I/O modules;

Support hot plugging for easy maintenance;

Equipped with comprehensive debugging and fault diagnosis functions.

Yaskawa CP-9200SH Controller

Core positioning and advantages of the product

Positioning: Yaskawa CP-9200SH is a high-end industrial controller that integrates sequential control and motion control, designed specifically for industrial machinery that requires high-speed synchronous operation.

Core advantages:

Modular structure, supporting flexible expansion;

Multi axis control capability, capable of controlling up to 224 axes;

Compatible with multiple communication protocols and I/O modules;

Support hot plugging for easy maintenance;

Equipped with comprehensive debugging and fault diagnosis functions.

Hardware system specifications

(1) Core module types and parameters

Module type, key model, core parameters

Power module PS-01 input: 85-132VAC/90-140VDC, power consumption ≤ 150W

PS-02 input: 170-230VAC, power consumption ≤ 150W

PS-03 input: 19.2-28.8VDC, power consumption ≤ 150W

CPU module CP-9200SH CPU 32-bit processor, program memory 1MB/2MB, supports dual CPU configuration

The SVA motion module can control up to 4 axes and supports position/speed/torque control

PO-01 has a maximum of 4-axis pulse output and supports positioning/zero point return

SVB maximum 14 axis MECHATROLINK control, maximum 224 axis expansion

Communication module CP-215IF has a transmission speed of 4Mbps and supports 30 standard sites

CP-217IF supports RS-232/RS-422/485, with a transmission distance of ≤ 300m

I/O module LIO-01 with 32 DI/DO points each

DI-01 DI 64 points

DO-01 DO 64 points

(2) Environmental and Physical Specifications

Working environment: temperature 0-55 ℃ (24-hour average ≤ 50 ℃), relative humidity 5% -95% (no condensation);

Anti vibration: Complies with JIS B 3502, with a half amplitude of 0.075mm at 10-57Hz and an acceleration of 9.8m/s ² at 57-150Hz;

Grounding requirements: protective grounding (Class 3, ≤ 100 Ω);

Installation weight: MB-01 full configuration 5400g, MB-03 full configuration 3400g.

Software and functional features

(1) Program Design

Programming languages: ladder diagram, SFC language;

Programming tool: CP-717 (desktop/laptop);

Program structure: Supports parent, child, and grandson layer level structures, with a maximum of 64 drawings.

(2) Core functions

Control functions: position control, speed control, torque control, electronic cam, electronic shaft synchronization;

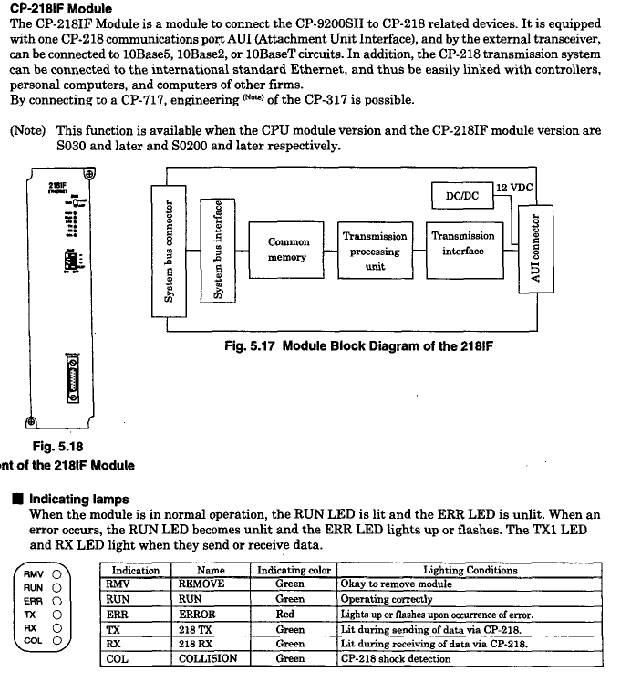

Communication function: Supports CP-213/215/216/217/218/225/2500 communication protocol, Ethernet (10Mbps);

Debugging and monitoring: data tracking (up to 4 sets x 16 data, 32k word memory), fault tracking (up to 500 fault definitions);

Special functions: pulse counting, frequency measurement, hardware position locking, hot swapping.

Installation and operation specifications

(1) Installation requirements

Installation location: Avoid direct sunlight, high temperature and humidity, dust, corrosive gases, vibration and impact environments;

Module installation: The power module is located on the left, the CPU module is in slot 0/1, and the fastening screws are tightened to prevent loosening;

Wiring specification: Separate the power and I/O lines for wiring, with a spacing of ≥ 200mm, to avoid noise interference.

(2) Start and Run

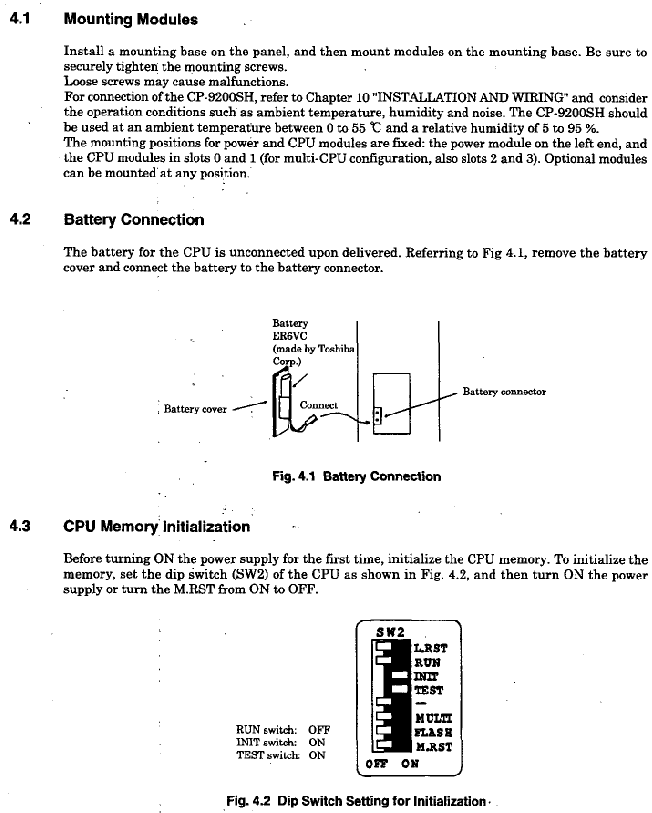

Initiation process: 1 Module installation → 2 Battery connection → 3 CPU memory initialization → 4. Connect CP-717 → 5. Load program → 6 Start running;

Operation mode: online operation mode (executing user programs), offline stop mode (program stops, output reset);

Hot plugging process: Set the BUS switch to HALT → Confirm that the RMV LED is on → Disassemble the module → Install the new module in HALT mode → Tighten the screws → Switch the BUS switch to ACT → Confirm that the RUN LED is on.

Fault handling and maintenance

(1) Fault diagnosis

LED indicator lights: RDY (ready), RUN (running), ALM (alarm), ERR (error), BAT ALM (battery alarm);

System registers: SW00040 (CPU status), SW00041 (error message), SW00200 (I/O error count);

Common faults: power supply error (check voltage range), communication error (check wiring and terminal resistance), program error (check SW00050 error code).

(2) Maintenance points

Battery maintenance: When the BAT ALM light is on, replace the lithium battery (ER6VC) and backup data to prevent loss;

Regular inspection: tighten screws, clean modules, check wiring;

Module replacement: Supports hot swapping, non hot swappable modules need to be powered off for replacement.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923