K-WANG

Yaskawa VARISPEED-626M5 frequency converter

Yaskawa VARISPEED-626M5 frequency converter

Product Core Overview

1. Product positioning and model system

Core products: VARISPEED-626M5 vector control frequency converter (Model: CIMR-M5) and VS-656MR5 power regeneration converter (Model: CIMR-MR5A), specially designed for high-precision motor drive of industrial equipment such as machine tools, supporting power regeneration function and better energy efficiency.

Voltage and power range:

200V level: frequency converter 5-50HP (3.7-37kW), converter 5-50HP (3.7-37kW, 7-60kVA);

400V level: frequency converter 7.5-60HP (5.5-45kW), converter 7.5-60HP (5.5-45kW, 9-70kVA).

Model naming convention: Taking CIMR-M5A27P5 as an example, "CIMR" is the series prefix, "M5" represents VS-626M5 frequency converter, "A" represents independent system use, "2" represents 200V level, "7P5" represents 7.5HP (5.5kW), and the suffix includes the structural type (0=open chassis type, 5=externally cooled heat sink type) and version number.

2. Core performance parameters

Control method: Sine wave PWM vector control, supporting speed control, torque control, and servo mode switching.

Speed regulation performance: The speed regulation range is from 40r/min to the maximum speed of the motor (up to 8000r/min), with a speed accuracy of ≤ 0.2% (rated speed).

Overload capacity: 120% rated current of frequency converter/1 minute; Converter 120% rated current/1 minute, 200% rated current/1 second.

Environmental adaptability: working temperature 0-55 ℃ (inlet temperature of heat sink ≤ 45 ℃), storage temperature -20-60 ℃, humidity ≤ 95% (no condensation), altitude ≤ 1000m, pollution level 2 environment.

Safety operation standards

1. Classification of safety warnings

Warning: Refers to the risk of fatal or serious personal injury, such as not cutting off power before wiring, operating with open covers, touching high-voltage terminals, etc.

CAUTION: May cause minor injury or equipment damage, such as unauthorized installation, incorrect parameter modification, failure to ground according to specifications, etc.

NOTE: Key operation tips to ensure the normal operation of the device, such as wiring spacing, heat dissipation requirements, etc.

2. Key safety requirements

Power off operation: Before wiring or maintenance, the power must be cut off and the capacitor must be discharged for 5 minutes (after the LED is turned off).

Grounding specifications: 200V level grounding resistance ≤ 100 Ω, 400V level ≤ 10 Ω, independent grounding (not shared with high current equipment such as welding machines and motors).

Installation restrictions: It is strictly prohibited to install on flammable materials. A heat dissipation space must be reserved and an external emergency stop circuit must be equipped.

Prohibited behaviors: Do not modify the product structure, do not connect AC power to the output terminals (U/T1, V/T2, W/T3), and do not conduct voltage withstand tests.

Receiving and unboxing inspection

1. Key inspection points

Model verification: Confirm that the equipment model is consistent with the order, and check the nameplate (including input/output specifications, serial number, weight, etc.).

Appearance and components: Check that the shell is not damaged during transportation, screws and connectors are not loose, and components are not missing.

Exception handling: If there is any damage or discrepancy, immediately contact the YASKAWA agent and do not install or operate it on your own.

2. Interpretation of key information on nameplates

Input specifications: 200V level frequency converter DC 270-325V, 400V level DC 540-650V (powered by the converter).

Output specifications: 3-phase AC 0-230V (200V level)/0-460V (400V level), corresponding to different capacities depending on the model (such as 12.9kVA).

Other identification: PROM version number, serial number (for after-sales traceability), structural type (open/cooled).

Installation specifications

1. Installation environment requirements

Avoid scenarios: direct sunlight, rain, snow, moisture, oil spills, salt spray, corrosive gases, dust/metal particles, severe vibrations, strong electromagnetic interference (such as welding machines), and near flammable materials (diluents, solvents, etc.).

Temperature control: The ambient temperature should be ≤ 55 ℃, and the inlet temperature of the heat sink should be ≤ 45 ℃. A fan or cooling device should be equipped to ensure heat dissipation.

2. Installation spacing and method

Installation method: Vertical installation (ensuring smooth heat dissipation airflow), fixed on the surface of non combustible materials such as metal.

Distance requirement (external cooling type with heat sink):

Front/back: ≥ 120mm;

Left and right sides: ≥ 5mm;

The cooling wind speed near the heat sink is ≥ 2.5m/s.

Open chassis type: front/back ≥ 150mm, left and right ≥ 50mm; when combining a converter of 11kW or more with a frequency converter of 7.5kW or less, the spacing must meet 28mm (horizontal) and 57mm (vertical).

3. Component identification

Core components of frequency converter (VS-626M5): mounting base, 4 mounting holes, heat sink, upper and lower cover plates, main circuit terminals (P/⊕, N/⊖, etc.), control power input terminal CHARGE LED、 7-segment LED display screen, output terminals (U/T1, V/T2, W/T3), grounding terminals, various signal connectors (51CN, 52CN, 6CN, etc.).

Core components of converter (VS-656MR5): main circuit power input terminals (R/L1, S/L2, T/L3), control power input terminals (A1/r, A2/t), DC output terminals (P/⊕, N/⊖), control power output terminals (P1, N1), grounding terminal CHARGE LED、 7-segment LED display screen.

Wiring specifications

1. Safety prerequisites for wiring

Wiring personnel: must be operated by qualified electricians and familiar with electrical safety regulations.

Power off confirmation: Before wiring, make sure the power is completely turned off to avoid electric shock.

Terminal tightening: Tighten the terminal screws (such as M6 screws 26lb in/2.94N · m) to the specified torque to prevent loosening and fire hazards.

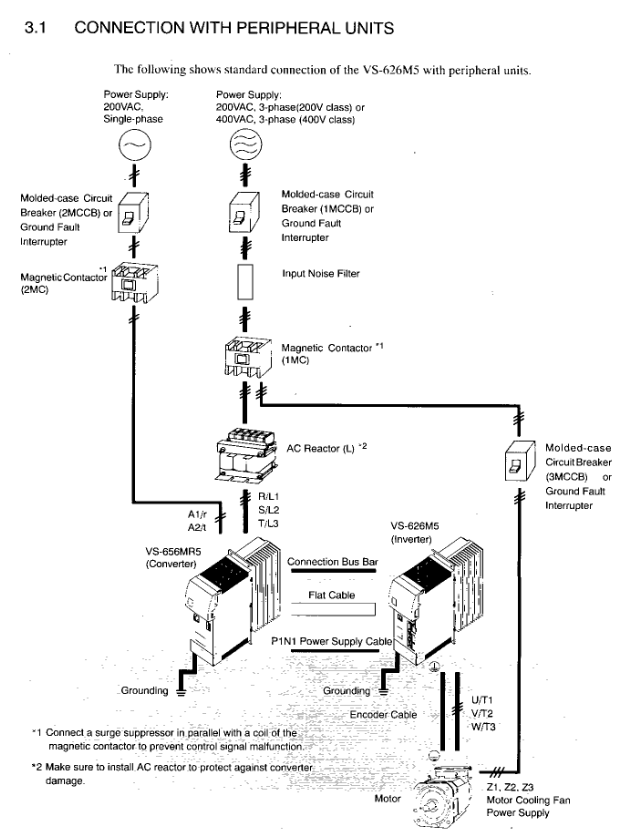

2. Main circuit wiring

(1) Core requirements

Voltage matching: Ensure that the power supply voltage is consistent with the rated voltage of the equipment (200V/400V level distinction).

Component installation:

The main circuit needs to be connected in series with MCCB (molded case circuit breaker) to protect the circuit;

The input end of the converter must be equipped with an AC reactor of corresponding capacity (to improve power factor);

Inductive loads (contactors, relays, etc.) need to be connected in parallel with surge absorbers or diodes, and are strictly prohibited from being connected to the output terminal of the frequency converter.

Prohibited connection: The input terminal must not be connected to phase advance capacitors or surge suppressors, and the output terminal must not be connected to AC power supply, phase advance capacitors, LC/RC filters, or magnetic starters.

(2) Wiring Details

Converter and frequency converter connection: The main circuit DC power supply is connected through a dedicated connection bus (P/⊕ → P/⊕, N/⊖ → N/⊖), with a torque of 4-5N · m; the control power supply is connected through a dedicated cable (P1 → P1, N1 → N1).

Motor connection: The output terminals of the frequency converter (U/T1, V/T2, W/T3) correspond to the U, V, and W terminals of the motor, ensuring that the motor rotates counterclockwise under the forward rotation command (load side perspective), with a wiring length of ≤ 20m.

Grounding treatment: Use grounding wires that comply with electrical standards, with the shortest possible length, and use single point grounding to avoid loop grounding (refer to Fig.11 and 12).

3. Control circuit wiring

(1) Signal type and connector

Control signal: including encoder signal (RS-422A specification), 12 bit digital reference signal, analog speed reference signal (0 ± 10V), sequence input signal (forward rotation, reverse rotation, emergency stop, etc.), fault output signal, etc.

Key connectors:

1CN: Control signal (digital reference, encoder output, etc.);

2CN: Encoder signal input, motor thermistor signal, etc;

6CN: Simulate speed reference, sequence input/output, fault code output, etc;

3CN: Digital operator connection.

(2) Wiring requirements

Separate wiring: Control the distance between the signal line and the main power line to be ≥ 30cm, avoid parallel wiring, and prevent interference.

Cable specifications: Shielded twisted pair cables are used for control signals, and both ends of the encoder signal cable shielding layer are grounded. The cable length is ≤ 20m.

Input method: 12 digit reference and 6CN sequence input support 0V common,+24V common, or external common (requiring 20-26V power supply), wired according to Fig.13 specifications.

4. Wiring inspection

Inspection items: Wiring correctness (refer to the connection diagram), terminal tightness, bare wire without contact with other terminals, no wire debris or screw residue in the equipment, and it is strictly prohibited to use the control circuit buzzer for inspection.

Operation process

1. Operation mode

Online operation mode: Execute user programs and I/O operations, RDY and RUN LEDs light up, ALM and ERR LEDs turn off when there are no faults.

Offline stop mode: Program stops, output reset, RUN/RDY LED off (trigger scenario: no scan time set, memory not initialized, serious fault, etc.).

2. Start the process

Complete module installation and battery connection (connect CPU battery separately);

Set CPU memory initialization through DIP switch;

Connect CP-717 programming tool;

Load user program;

Start running, the device performs self diagnosis (memory, ROM, CPU function testing).

3. Test Run

Preparation before operation: Clear operational obstacles, notify surrounding personnel, and confirm safety.

Power startup sequence: First turn on the control power supply (or turn it on simultaneously with the main circuit power supply), then turn on the main circuit power supply; The order of closure is reversed.

Status confirmation:

Control power on: converter 7-segment LED displays "- u", frequency converter displays "- b";

Main circuit power on: The converter display switches to "- b", the CHARGE LED red light is on, and the motor cooling fan starts (airflow direction conforms to Fig.16).

Operation: Input the operation signal (FWD/REV), gradually increase the speed reference (starting from 0%), verify the motor rotation (clockwise and counterclockwise), smooth acceleration and deceleration, and no abnormal vibration or noise (kHz level static sound is normal control noise).

4. Interpretation of 7-segment LED display

Inverter display:

- b ": No running instruction (base block);

- r ": Running;

Fault display: alternately display the fault number and fault code (such as "2-42" indicating that the second fault is the disconnection of the motor thermistor).

Converter display:

- u ": The main circuit is not powered on or under voltage;

- b ": Not running;

Fault display: alternately display the fault number and fault code (such as "1-01" indicating that the first fault was overcurrent).

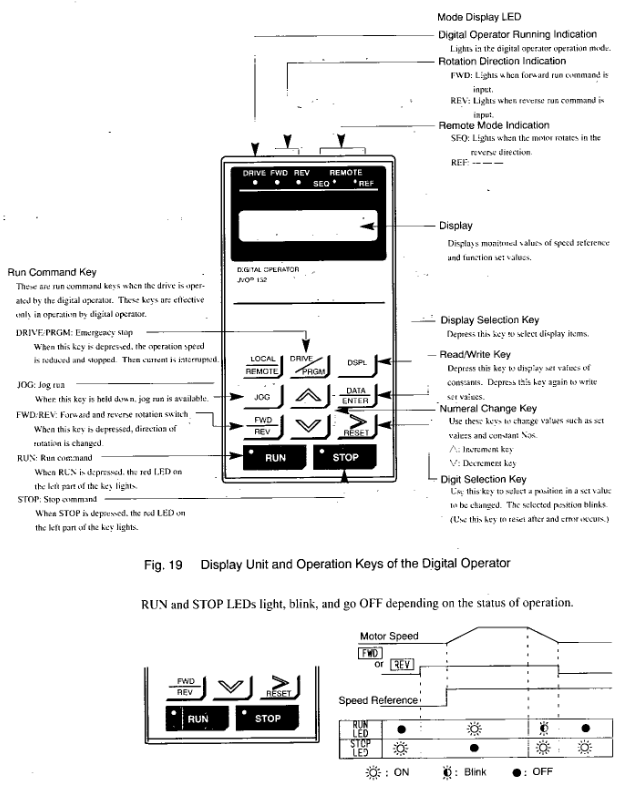

Digital operator (JVOP-132) operation

1. Installation and safety

Installation: Connect through a 3CN connector, use a dedicated extension cable (72616-W5301/5303), tighten the connector screws, and install the cable fixing bracket to prevent detachment.

Safe operation: Before disassembly, the power must be turned off and the capacitor discharge must be completed (LED off).

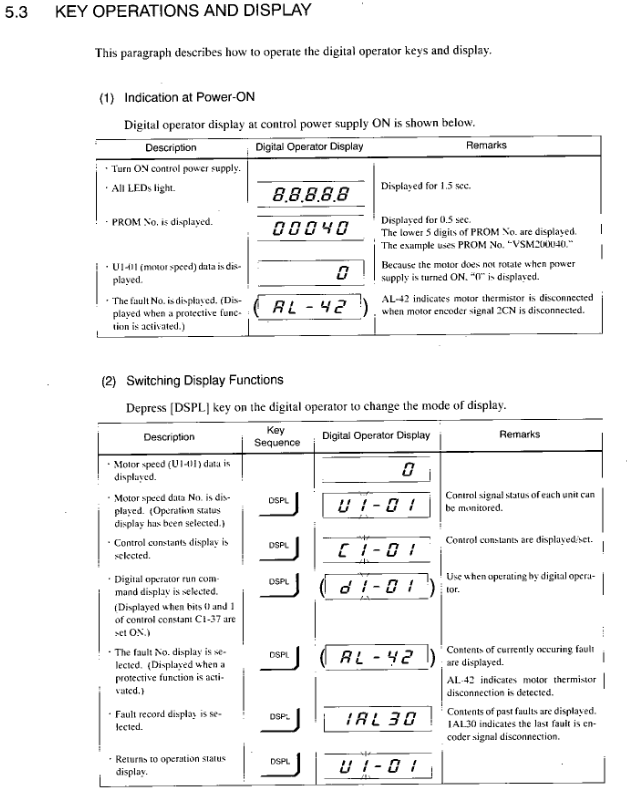

2. Core functions

Status monitoring: Display operating parameters such as control signal status, motor speed, output current, etc. (refer to APPENDIX 5).

Parameter settings: View and modify control constants (such as speed proportional gain, rated speed, etc., refer to APPENDIX 6), some parameters (C1-25 to 59, etc.) need to be stopped for modification.

Fault handling: Display current fault codes and historical fault records (up to 6), support fault reset.

Independent operation: No external sequence input or speed reference is required, and testing operations such as jogging, forward and reverse rotation can be achieved through the operator (with parameters set to C1-37).

3. Key operations

Mode switching: Press the [DPL] key to switch between operating status display, control constant display, fault display, and other modes.

Parameter modification: Select the constant number → Press the [DATA] key to view the current value → Modify the value → Press the [DATA ENTER] key to write (display "End" for confirmation).

Fault reset: Press the [RESET] key in fault display mode, and before resetting, turn off the external operation command (FWD/REV/ORT).

Maintenance and Inspection

1. Key points for regular maintenance

Daily inspection: tighten terminal screws, clean modules (heat sinks, circuit boards), and check wiring integrity.

Regular inspection (Table 18):

External terminals, mounting bolts, connectors: no looseness;

Heat sink: no dust accumulation (blown with 4-6kg · cm ⁻ ² dry compressed air);

Printed circuit board: no conductive dust or oil stains (replace if unable to remove);

Cooling fan: No abnormal noise or vibration, needs to be replaced after 20000 hours of operation;

Smooth capacitor: no discoloration or odor (5-year inspection, replace if necessary);

Motor bearings: No abnormal noise or temperature rise, maintained for 12000 hours or 2 years.

2. Component replacement cycle (guide)

Remarks on component replacement cycle

Cooling fan (frequency converter/inverter) to be replaced with new parts within 2-3 years

After a 5-year inspection, decide whether to replace the smoothing capacitor

Determine whether to replace the aluminum electrolytic capacitor on the circuit board after a 5-year inspection

Replace the fuse with a new one after 10 years

Motor bearings require 12000 hours or 2 years of disassembly, maintenance, or replacement

Replace the motor cooling fan with a new one after 15000 hours or 2 years

Contact YASKAWA agent for equipment overhaul of 20000 hours or 5 years

3. Maintain safety regulations

Power off requirement: Cut off the main circuit and control power before maintenance, and confirm that the CHARGE LED and 7-segment LED are turned off (capacitor discharge completed).

Operation restrictions: Only authorized personnel are allowed to operate. Remove metal items such as watches and bracelets, use insulated tools, do not touch CMOS components (which are susceptible to static electricity damage), and do not plug or unplug cables/connectors with power on.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923