K-WANG

YOKOGAWA FFCS COMPACT CONTROL STATION IN CENTUM CS3000 R3

YOKOGAWA FFCS COMPACT CONTROL STATION IN CENTUM CS3000 R3

Overview

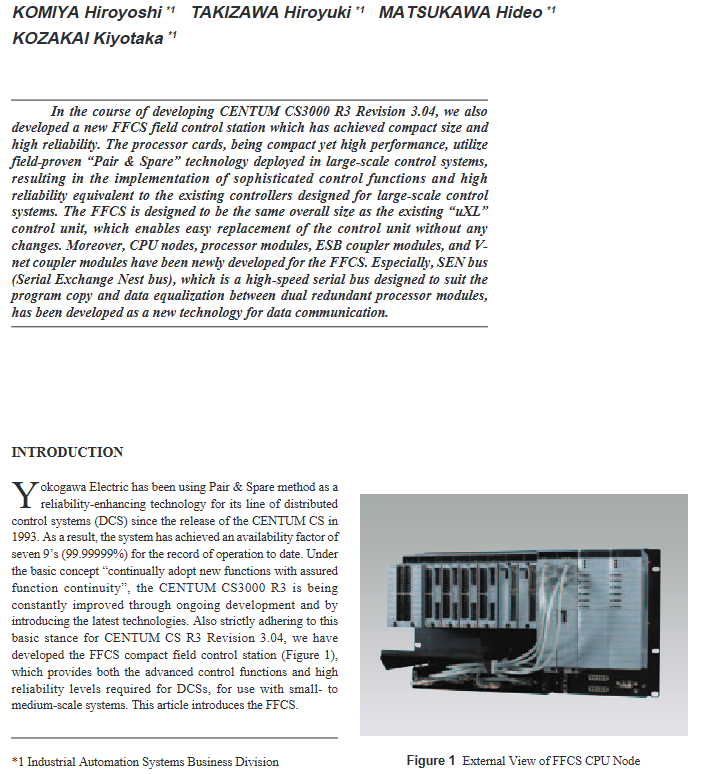

Yokogawa Electric released a technical report (No. 38) in 2004, focusing on the newly added FFCS compact field control station in the CENTUM CS3000 R3 V3.04 version. As a field control station (FCS) designed specifically for small and medium-sized systems, FFCS inherits the high reliability and advanced functions of large DCS, achieves compactness through a new hardware design, and is compatible with existing uXL systems, supporting low-cost upgrades, enriching the FCS product line of CENTUM CS3000 R3 (including standard, extended, renewable, and highly distributed types).

FFCS Core Features

Specific description of characteristic category

Compact and compatible volume is 1/5 of traditional control units; The external dimensions are consistent with the uXL control system control unit and can be directly replaced, maximizing the reuse of existing assets

High reliability adopts Pair&Spare dual redundancy technology, with no instantaneous switching control in case of failure; System availability reaches 7 9s (99.99999%)

Advanced features with complex control functions equivalent to large controllers, supporting system software reuse (common for small and medium-sized/large factories)

Scalable CPU nodes can install up to 8 I/O modules; Can connect up to 3 extension nodes (directly coupled nodes+remote nodes)

Hardware compatibility is compatible with the I/O module (IOM) and field network I/O module (FIO) of CENTUM CS3000 R3

Hardware configuration details

(1) Overall redundant architecture

FFCS supports full hardware dual redundancy configuration, with core redundant components including processor modules, power units (PW481/PW482/PW484), communication buses (SEN/ESB/ER/V-net), and I/O modules, ensuring that a single point of failure does not affect system operation.

(2) Core hardware components

CPU node

The smallest system core can run independently and can install up to 8 IOM modules;

Scalability: Supports connecting 3 expansion nodes (directly coupled nodes+remote nodes);

Interface module: EC401 (ESB bus coupler) is required to connect directly coupled nodes, and EB401 (ER bus main interface module) is required to connect remote nodes.

CP401 processor module

Redundant design: dual MPU architecture, synchronous computing+cross checking, detecting instantaneous errors;

Hardware Reuse: Integrated with CENTUM CS3000 mature CP345 processor card and SB301 interface card, software compatible;

Packaging form: Modular packaging (replacing traditional card design), built-in nickel hydrogen battery (environmentally friendly alternative to nickel cadmium battery), backup main memory;

Core function: Achieve fault free instantaneous switching and ensure control continuity.

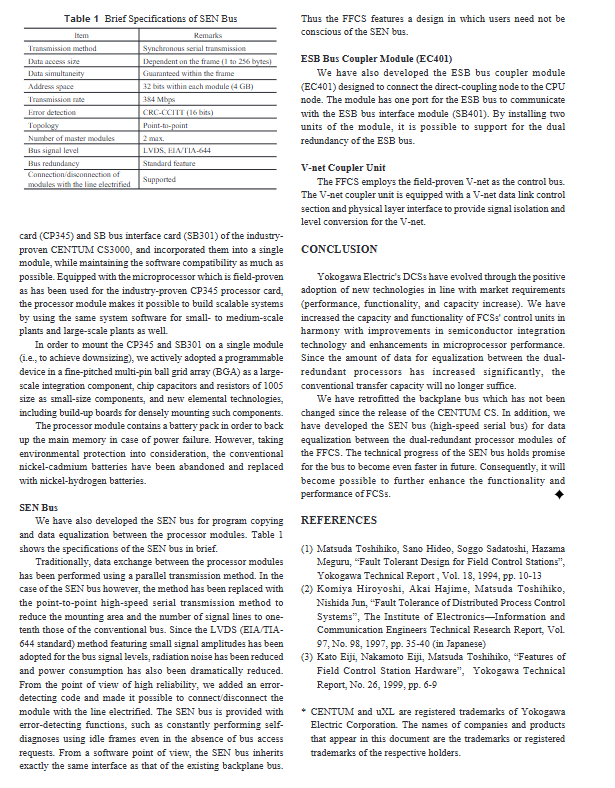

The SEN bus (Serial Exchange Nest bus) is specifically developed for program copying and data synchronization of dual redundant processor modules, with the following key parameters:

Specific specifications of parameter items

Transmission method: synchronous serial transmission

Transmission rate 384 Mbps

Data access size 1-256 bytes (depending on frame structure)

Address space of 32 bits per module (4 GB)

Signal level LVDS (EIA/TIA-644 standard)

Topology point-to-point structure

Redundancy feature standard configuration

Error detection CRC-CCITT (16 bits), idle frame self diagnosis

Live operation support module for live plugging and unplugging

Advantages: Compared to traditional parallel transmission, the signal line and installation area are reduced to 1/10, reducing radiation noise and power consumption.

Other key modules

EC401: ESB bus coupler module, 1 ESB bus port, dual module configuration supports ESB bus redundancy;

V-net coupling unit: integrates V-net data link control and physical layer interface to achieve signal isolation and level conversion;

EB401/EB501: ER bus master/slave interface module, used to connect remote nodes;

SB401: The ESB bus is an interface module used to expand communication between nodes and CPU nodes.

System configuration and connection

Minimum system: Only CPU nodes (including 8 IOM modules) meet basic control requirements;

Expansion system: CPU nodes+up to 3 expansion nodes (directly coupled nodes/remote nodes) to expand I/O capacity;

Connection logic:

CPU node ↔ Directly coupled nodes: EC401 (CPU end)+SB401 (expansion end)+ESB bus;

CPU/Directly Coupled Node ↔ Remote nodes: EB401 (master)+EB501 (slave)+ER bus.

Adaptation scenarios and value

Adaptation scenario: Distributed control requirements for small and medium-sized factories, especially suitable for space constrained and high reliability scenarios;

Upgrade value: uXL system users can directly replace control units, minimize equipment investment, and reuse existing assets;

Technical value: The SEN bus lays the foundation for subsequent FCS functional upgrades (such as greater data synchronization), and the dual redundancy design ensures production continuity.

Key issues

Question 1: How can the FFCS compact on-site control station achieve compact design while ensuring reliability and control functions comparable to large DCS?

Answer: ① Reliability guarantee: Adopting Yokogawa's mature Pair&Spare dual redundancy technology, the processor module dual MPU synchronous calculation+cross validation, no instantaneous switching control in case of failure, system availability reaches 7 9s (99.99999%), consistent with large DCS; ② Functional reuse: Integrate the validated CP345 processor card and SB301 interface card core assets of CENTUM CS3000 on hardware, and universal system software at the software level to ensure consistent complex control functions; ③ Compact implementation: Adopting high-density installation technologies such as BGA packaging programmable devices, 1005 size components, and multilayer boards, multiple traditional card components are integrated into a single modular package, compressing the volume to 1/5 of traditional control units.

Question 2: What are the core technical advantages of FFCS's SEN bus compared to traditional parallel transmission buses? What practical value do these advantages bring to the operation of the system?

Answer: The core advantages and practical value are as follows: ① Transmission performance: With a speed of 384 Mbps, it meets the large data synchronization requirements of dual redundant processors and solves the problem of insufficient transmission capacity of traditional buses; ② Hardware optimization: point-to-point serial transmission, reducing signal lines and installation area to 1/10, reducing hardware costs and space occupation; ③ Stability improvement: Adopting LVDS level standard, with low radiation noise and low power consumption, combined with CRC-CCITT error detection and idle frame self diagnosis function, to improve transmission reliability; ④ Convenient operation and maintenance: supports module live plugging and unplugging, maintenance can be carried out without stopping the machine, reducing the risk of production interruption; ⑤ Compatibility: Inheriting the existing backplane bus software interface, users can use it without additional adaptation.

Question 3: What are the core advantages of upgrading to FFCS for existing uXL control system users? What hardware compatibility issues should be noted during the upgrade process?

Answer: Core upgrade advantages: ① Seamless replacement: FFCS has the same external dimensions as the uXL control unit and can be directly replaced without changing the installation structure, maximizing the reuse of existing assets; ② Performance improvement: Achieve high reliability (dual redundancy) and advanced control functions equivalent to large DCS, meeting higher production requirements; ③ Flexible Expansion: Supports up to 3 expansion nodes and 8 I/O modules, and can be flexibly expanded according to production scale. Compatibility issues to be noted: ① Power supply unit: Use the PW481/PW482/PW484 models specified in the document to ensure power supply matching; ② I/O module: Only compatible with the IOM (I/O module) and FIO (Field Network I/O module) of the CENTUM CS3000 R3 series. It is necessary to confirm whether the existing module belongs to this series; ③ Expansion interface: When connecting expansion nodes, dedicated interface modules such as EC401 and EB401 must be used in conjunction, and other types of interface cards cannot be mixed.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923