K-WANG

YOKOGAWA CENTUM VP Integrated Production Control System

YOKOGAWA CENTUM VP Integrated Production Control System

Overview

The General Overview Manual for Yokogawa Electric's CENTUM VP Integrated Production Control System (Document Number: TI 33J01A10-01EN) is the 4th edition released in 2016, which provides a detailed introduction to the system's core concepts, configuration architecture, functional characteristics, engineering environment, and full lifecycle support. As the 8th generation CENTUM series product, CENTUM VP is the core platform of Yokogawa VigilantPlant solution, designed for control and management of multi industry factories, with high reliability, openness, and flexible scalability.

Core philosophy and core advantages

(1) Core concept

Build a full value chain operation support system around the three dimensions of "See Clearly, Know in Advance, Act with Agility":

See Clearly: Real time capture of factory wide data, precise push of key information, reducing information overload and blind spots;

Know in Advance: Integrate historical, real-time, and predictive data to support rapid and intelligent decision-making, and mitigate operational risks;

Act with Agility: Accelerate task collaboration, automate best practices, enhance production flexibility and bottleneck prediction capabilities.

(2) Core advantages (by role/scenario)

Description of core advantages of applicable objects/scenarios

Unified control/security/asset intelligence interface by operators to avoid information overload; Continuous Systematic Best Operating Practices

The integrated engineering environment of Engineer AD Suite supports flexible design, and the control application and I/O configuration can be independently adjusted

Controller performance 99.99999% availability, dual redundancy design, fault free instantaneous switching, supports N-IO software configurable I/O

Production management is compatible with S95/B2MML standards, achieving MES/enterprise system integration; Built in network security authentication

Maintenance personnel upgrade and modify online without any single point of failure; 40 year downward compatibility, protecting long-term investments

Integrated solution for project implementation (DCS/SIS/PIMS, etc.) to reduce integration risks and accelerate project delivery

System configuration and core components

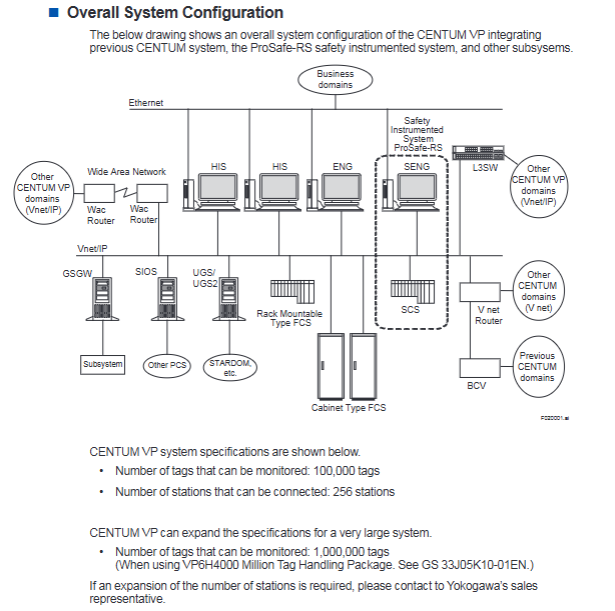

(1) Overall architecture

The system is centered around "HIS+FCS+control network" and supports full-scale deployment from small to super large (1 million tags). It can integrate security systems, third-party devices, and remote sites to form a unified control ecosystem.

(2) Key component description

core component

HIS (Human Interface Station): Based on Windows system, supports desktop/open/closed consoles, compatible with 16:10/4:3 displays, multiple HIS mutual backup without single point of failure;

FCS (Field Control Station): independently developed by Yokogawa, supporting cabinet/rack installation, equipped with dual redundant processors, power and I/O modules, supporting online maintenance and remote deployment (IEC Zone 2/Class I Div. 2);

Control network (Vnet/IP): 1Gbps redundant Ethernet, compliant with IEEE802.3 standard, supports 5ms full network time synchronization, ensuring deterministic communication.

Auxiliary components

ENG (Engineering Station): Install AD Suite engineering software, supporting modular/non modular engineering design;

Gateway station (GSGW/USGS/BIOS): GSGW is used for subsystem monitoring, UGS/UGS2 integrates STARDOM/PLC, SIOS connects to third-party PCS (OPC interface);

Communication relay devices: BCV (connecting old CENTUM system), AVR (interconnecting Vnet/IP and V net), WAC Router (connecting Vnet/IP domains across WAN).

integrated system

ProSafe-RS: T Ü V SIL3 certified safety instrumented system, supporting ESD/PSD/F&G/BMS functions, sharing operating environment with CENTUM VP to achieve integrated safety and control;

Digital fieldbus: supports mainstream protocols such as Foundation fieldbus, HART, PROFIBUS-DP, Modbus TCP/IP, ISA100.11a, etc;

Third party integration: Through OPC DA/A&E interface, data exchange with third-party PCS and ERP systems is achieved.

Detailed explanation of core functions

(1) Engineering Features (AD Suite)

AD Suite is an integrated engineering environment added to CENTUM VP R6, supporting full lifecycle engineering management. Its core functions are divided into standard and optional features

Function type, specific function, core value

The standard function non modular project first determines the hardware configuration, and then carries out engineering design on a hardware by hardware basis

History management automatically saves engineering change records, supports traceability and retrieval

AD Server centrally manages engineering data and projects, supports backup/recovery

Optional modular engineering reuse design modules (control logic/alarm attributes, etc.) to improve efficiency and consistency

Batch editing and modification of multiple module parameters, supporting consistency verification

Change control is managed through ModPack to manage the change process, recording test results and responsible parties

Dependency analysis analyzes the correlation between control logic/I/O/graphic labels and evaluates the impact of changes

Optimize parameter management by comparing design values with on-site actual values, supporting batch distribution and synchronization

(2) Control Function (FCS)

High reliability design: The processor, power supply, I/O module, and network are fully redundant, and the Pair&Spare architecture enables seamless fault switching;

Flexible control capability: supports adjustable control, advanced control, complex sequential control, and batch control, adapting to different scale requirements through functional block combinations;

Unit monitoring: defining multiple devices as a single unit for unified operation, simplifying batch and continuous process management;

Online maintenance: supports engineering data modification and module replacement without interrupting process control.

(3) Human Computer Interface Function (HIS)

Integrated operation: Integrate CENTUM VP control data, ProSafe RS security alerts, and PRM asset data to achieve seamless management;

Compliant design: Complies with EEMUA 191 alarm system design standards to reduce the risk of alarm storms;

Flexible display: Supports multi monitor deployment, with operation windows that can be moved across screens to adapt to different monitoring scenarios.

(4) Openness and Interoperability

Global HIST Network: Set up testing sites in Japan, the Netherlands, the United States, and Singapore to verify interoperability with non Yokogawa equipment;

High speed open network: Vnet/IP supports 1Gbps transmission and is compatible with TCP/IP, ensuring real-time data updates for large-scale projects;

Standard interface support: Implement information flow, advanced control, and alarm management with external systems through OPC servers.

Full lifecycle support

(1) Project Phase

Accurate cost estimation: FCS load can be calculated during the design phase, and label authorization is only divided into three levels: 8000 points (small), 100000 points (medium and large), and 1000000 points (multi factory interconnection), reducing change costs;

Virtual testing function: Control and operation functions can be tested without hardware, accelerating project progress and supporting the establishment of Operator Training System (OTS).

(2) Operation and Upgrade Phase

Convenient upgrade: PC based sites can be upgraded with just one click, and FCS can upgrade new features as needed without the need for mandatory updates;

Smooth migration: supports the migration of old CENTUM systems (such as CS3000, uXL) to third-party DCS, and can reuse assets such as on-site cables and I/O modules;

RIO system upgrade: The RIO system of CENTUM CS/CS3000/VP can be upgraded to the latest FCS (A2FV70 ) without changing the field equipment interface.

Key specifications of the system

Specific parameters of specification items

Maximum monitoring tag count of 1000000 points (requires VP6H4000 Million Tag Handling Package)

Maximum number of connected sites 256 (expandable, sales need to be contacted)

Control network speed 1Gbps (Vnet/IP)

Time synchronization accuracy 5ms (Vnet/IP network wide)

FCS availability 99.99999%

ProSafe RS safety system certification complies with IEC 61508 SIL3 standard

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923