+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

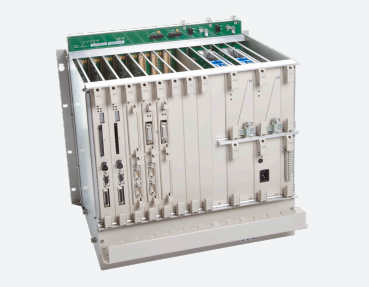

ABB Advant® Controller 450

ABB Advant® Controller 450

ABB Advant® Controller 450

Advant Controller 450 is a high-end

process controller. Its high processing

capacity and wide-ranging process

and system communication capabilities

make it the ideal choice for demanding

applications, either standing alone

or as part of a ABB Ability™ System

800xA with Advant® Master

Does everything in process control

Advant Controller 450 can do “everything” in process

control, not only perform logic, sequence, positioning

and regulatory control but also manage data and text

generally and produce reports. It can even perform

selftuning adaptive, PID control and fuzzy logic control.

The station is programmed graphically in AMPL,

as are all other controllers in Advant OCS with Master

software. The already rich library of program elements/

function blocks can be augmented with user-developed

blocks created in AMPL.

A full complement of I/O

The range of process I/O modules is complete, covering

general-purpose analog an digital inputs and outputs

at different ratings as well as Pt100, thermocouple

and pulse inputs. Specialized interfaces are provided

for accurate digital positioning, switchgear integration,

variable-speed motor control, telecontrol and

communication with other makes of programmable

controllers. The overall I/O capacity is as high as

5,700 I/O points.

Both central and distributed I/O are available

Central I/O (S100 I/O) modules are plugged into I/O

racks installed in close proximity to the CPU rack/

cabinet. Distributed I/O (S800 I/O) stations can be

installed up to 13,3 km (8,2 miles) away, communicating

over Advant Fieldbus 100, a high-speed serial

communication bus.

The controller that stays in touch

Advant Controller 450 supports a wide range of

communication protocols, making it easy to design

the optimal control system architecture for every

application. These protocols include:

• MasterBus 300/300E for communication with other

member stations of Advant OCS at the Control

Network level.

• GCOM for communication with AdvaSoft for Windows

and external computers. The easy, powerful, for

external computers to access process data in Advant

OCS. Both ways.

• Advant Fieldbus 100 for communication with distributed I/O stations, programmable controllers and

motor drives.

• RCOM/RCOM+ for long-distance communication

with remote terminals, using dedicated or dial-up

telecommunication lines.

• RS232 for communication with external computers

at the process signal/device level by ABB’s EXCOM

protocol and for local printout of data, reports,

event messages and alarms.

• MVI (Multi-Vendor Interface) for communication

with other makes of control systems over MODBUS I,

Siemens 3964R or Allen-Bradley’s DF1.

• Profibus DP for communication with other makes

of controllers and with stand-alone I/O systems

made for this popular communication protocol.

• Telecontrol communication with dispatch centers,

power stations and remote terminals.

• SPA bus communication with relay protection units.

Redundancy at all levels

To achieve the highest possible availability, Advant

Controller 450 can be equipped with backup redun dancy for MasterBus 300/300E, Advant Fieldbus

100, power supplies, voltage regulators, backup

batteries, battery chargers, central units (CPUs and

memories) and I/O boards for regulatory control.

The central unit redundancy is of a patented hot standby

type, offering bumpless changeover in less than 25 ms.

Enclosures

Advant Controller 450, equipped with local S100 I/O,

consists of one CPU rack and up to five I/O racks.

Optical bus extension makes it possible to distribute

the S100 I/O up to 500 m (1,640 ft.) away, thus

reducing the amount of field cabling required.

The I/O racks are designed for installation in cabinets

with a swing-out frames, permitting access to both

the front and the rear of racks for ease of installation

and maintenance. The external connections are routed

through connection units normally fitted inside, at

the back of the cabinets for marshalling and noise suppression purposes. Cabinets with various degrees

of protection are available, e.g. ventilated, tropical

and sealed, with or without heat exchangers.

Power supply alternatives

Direct (unisolated) 24 V d.c.

D.C., by isolated DC/DC converter 1 24/48 V d.c.

A.C. (isolated) 1 120/230 V, 47-63 Hz

Basic capacity and performance

Primary memory 16 MB

Available for application approx. 13,4 MB

Processing capacity index 2 3-4

Program execution cycle; Selectable 10ms-2s or 5ms-32s

S100 I/O capacity 3, 12

S100 I/O racks Up to 5

S100 I/O modules Up to 100

Analog input modules Up to 32

Analog output modules Up to 32

Digital input modules Up to 48

Digital output modules Up to 48

Total I/O capacity (S100 & S800 I/O) 3

I/O channels Up to 5,700

AI channels (incl. calculated) Up to 900

AO channels (incl. calculated) Up to 900

DI channels (incl. calculated) Up to 2,300

DO channels (incl. calculated) Up to 1,400

Software options 3

Advanced arithmetic, basic regulation

and support for analog thyristor converters

Advanced PID control,

Auto-tuning Adaptive Controller

Fuzzy logic control

Advant Operator Workplace support

MasterBatch 200/1 support

User defined PC elements

Object support via Advant Fieldbus 100

Hardware options 3

Redundant CPU board, PM511 1 Up to 2

Interface modules (additional) 4 Up to 12/14

• V.24/RS232 interface, CI531, 2 ch. 5, 14 Up to 4

• MasterBus 300/300E interface

- Without slave CPU, CS513A/SC510 Up to 2

- With slave CPU, CS513A/SC520 6,7 Up to 6

• GCOM interface, CI543/SC510 10 Up to 5

• RCOM/RCOM+ interface, CI532Vxx, 2 ch.10 Up to 5

• MasterFieldbus interface, CI570 Up to 7

• Advant Fieldbus 100 interface, CI522A 14 Up to 8

• Profibus DP interface, CI541V1 14 Up to 8

• Modbus interface, CI532V02 & CI534V02, 2 ch. Up to 5

• Siemens 3964R interface, CI532V03, 2 ch. Up to 5

• Allen-Bradley DF1 interface, CI534V4, 2 ch. Up to 5

• Telecontrol & SPA bus, CI535Vxx 13 Up to 5

Voltage regulator, SR511 (Tot. 2) 1

Battery charger, SB510 Up to 2

Cabinets 3, 8,11

RM500V1, IP21, IP41 or IP54: WxDxH 800x512x2125 mm,

(31.5"x20.2"x83.7")

RM500V2, IP21, IP41 or IP54: WxDxH 700x637x2225 mm,

(27.6"x25.1"x87.6")

1 Can be combined for dual redundancy.

2 Compared to Advant Controller 410 (approx. value).

3 See Advant OCS with Master Software Product Guides for details.

4 Depending on whether one or two PM511 are used.

5 Up to one printer, two EXCOM and four MasterView 320 connections.

6 Standard and low-load MasterBus 300/300E cannot coexist in the same

controller.

7 Up to six.

8 Corresponds to the NEMA protection classes 1, 2 and 5.

9 With heat exchanger.

10 Up to nine channels (GCOM + RCOM + Multi-Vendor interface).

11 Can be combined into bays of multiple cabinets.

12 With the optical bus extensions up to 25 S100 I/O racks can be connected.

13 See Advant OCS and Telecontrol Product Guides for details.

14 Up to eight channels (AF100 + Profibus + LONWORKS + EXCOM).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

51

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923