+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

ABB AO2000 Advance Optima Continuous gas analyzers

ABB AO2000 Advance Optima Continuous gas analyzers

ABB AO2000 Advance Optima Continuous gas analyzers

DescriptionApplication Information from the AO2000 gas analyzer can be transferred to a PC or DCS via

the Modbus. Measurement values, status signals and also signals of analog and

digital inputs and outputs are thus available for further usage.

Using the AO-MDDE server the signals can be integrated into standard software

(e.g. Excel, Visual Basic or LabVIEW). For further information, see Chapter 4

“AO-MDDE server and demo programs”, page 3535. AO-MDDE can be

downloaded from the DVD-ROM which is delivered together with each gas

analyzer. AO-MDDE does not support Modbus over TCP/IP.

Basic documents Modbus Application Protocol Specification V1.1b, December 28, 2006

Modbus over Serial Line Specification and Implementation Guide V1.02,

December 20, 2006

Modbus Messaging on TCP/IP Implementation Guide V1.0b, October 24, 2006

These documents are available at http://www.modbus.org/specs.php.

Interfaces and

connection versions

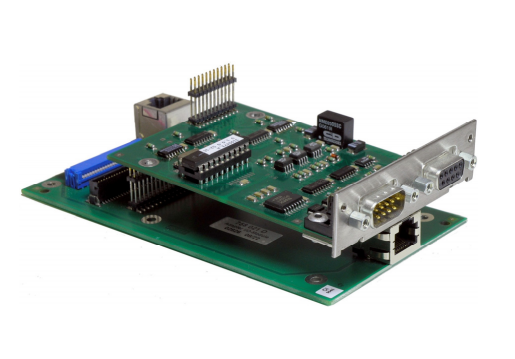

The RS232 and the RS485 interface located on the RS232/RS485 module in

AO2000 are supported, where only one can be operated at a time. Connection

versions are described in Chapter 3 “Modbus connection”, page 30.

As an alternative, the Ethernet 10/100BASE-T interface can be used for data

transmission via Modbus TCP/IP protocol (from software version 5.1, see page 7).

Transferred data Read Write Example

Measurement values x – CO, NO, H2, etc.

Analog inputs x – Indication of mA-values of external analyzers

Analog outputs x – Indication of mA-values of measurement values or calculated

values (function block application)

Digital inputs x – Indication of external status signals

Digital outputs x – Measurement range feedback, indication of solenoid or pump

controls

Bus analog inputs x x Entering analog values into the function block application

Bus analog outputs x – Outputting analog values from the function block application

Bus digital inputs x x Control of functions such as auto calibration, measuring range

control, etc. after function block configuration

Bus digital outputs x – Indication of all functions integrated by function block configuration such as alarm signaling etc.

Modbus configuration x – Indication how many components, AOs, DOs, etc. have been

configured or are in the gas analyzer

Status signals x – Indication of failure, maintenance mode, maintenance request

Measurement range

feedback

x – Index of the active measurement range

Measurement range

configuration

x – Measurement range limits (start and end value)

Measurement range

drift values

x – Offset drift, amplification drift, delta offset drift, delta amplification

drift

QAL3 calibration data x – Setpoints and actual values, measuring range and date of last

calibration (not available in analyzer modules Limas11, Uras14,

Magnos16, Magnos106, Caldos15, Caldos17, and MultiFID14)

Data transfer For data transfer a combination of frames is used, that consists of 1/0 information,

united to one or more telegrams.

Frame The transfer values are decomposed in bytes (= 8 bit). Each of these bytes is

completed by one start-bit, possibly one parity-bit (even number of “1”) and one

stop-bit. In the following description the term “byte” will be used, even if ten or

eleven bits will be transferred including the start-, stop- and parity-bits.

Telegrams The Modbus telegrams consist of the following frames:

address (1 byte), function (1 byte), data (n bytes) and check sum (2 bytes).

The telegrams also take on the “shake-hands-function”: each telegram from

master to slave must be responded, before a new telegram is allowed to be

transmitted. The computer has to have in a adequate supervision, for excluding

non answering bus participants (time-out-supervision).

Admissible addresses As addresses for the participants of the bus the numbers 1 to 255 are admitted.

The address 0 is the global address (broadcast-address). When this address will

be used in a telegram, all participants accept this telegram without an acknowledg ment to the master.

Functions Code Term Function

01 Read coil status Reading of binary values of type coil

02 Read input status Reading of binary values of type status

03 Read holding registers Reading of 16 bit holding-registers

04 Read input registers Reading of 16 bit input-registers

05 Force single coil Setting of a single binary value

06 Preset single register Set of a single 16 bit-register; for DINT or

REAL two telegrams are necessary

08 Loopback diagnostic test Testing telegram for diagnostics of the

communication capability of slave

15 Force multiple coils Set of several successive binary values

16 Preset multiple registers Set of several successive 16 bit-registers

Check sum The check sum is calculated over all bytes of one telegram without the start-,

stop- and parity-bits.

Transfer rules The neutral position of the data line corresponds with the logical “1”.

A distance of more than 3.5 bytes, however at least 10 ms is defined as separation

between two telegrams. For the beginning of the data transfer the neutral position

of the data line must be observed.

Integration The AO2000 Modbus/TCP server expects requests from the current IP addresses

via the communication port. A maximum of 4 clients can be connected to the

Modbus/TCP server of an AO2000 at the same time. If the connection to a client

breaks down, the connection status in the Modbus/TCP server is enabled again

after a max. 60 seconds.

Reading out data

from the AO2000

Modbus/TCP server

The following procedure must be executed on the Modbus client, in order to

receive data from the AO2000 Modbus/TCP server:

1. Establish a TCP connection to port 502 on the server.

2. Create a Modbus request.

3. Send the Modbus request incl. the Modbus/TCP MBAP Header.

4. Wait for a response to the same TCP connection.

5. Read the first 6 bytes of the response; these state the length of the response.

6. Read the remaining bytes of the response.

Functions, addresses

and registers

The supported functions and the addresses and registers of Modbus over TCP/IP

are equivalent to those of Modbus over RS232/RS485.

Function code 43 with MEI 14 (MEI = Modbus Encapsulated Interface) is used to

read the device parameters to

read measured values,

transfer simulation data,

apply reference material.

Address assignment

of the device

parameters for the

function code 43

There is read access to the device parameters.

Measurement components are mapped with the following structure:

Name

Measurement range start

Measurement range end

Unit

The number of the first measured values register is listed under BasisM in the

device parameters list.

The measured value status is implemented as NAMUR status:

Bit Assignmant

0 Error

1 Maintenance

2 Maintenance request

3 Beyond specification

4 Test operation, simulation measured value transmitted

5…15 Reserved for extensions

16…31 Vendor-specific

The number of the first simulation data register is listed under BasisS in the device

parameters list.

The number of the register to apply reference material is listed under BasisR in the

device parameters list. Maximum 32 Bus DIs are reserved for transferring

reference material.

The register "status of application" is used for feedback of the DIs for which a

hardware digital output is connected. When reference material is applied, the

status "maintenance" is set and a message is displayed on the gas analyzer's

screen.

Name Object ID Encoding Table Attribute Description

VendorName 0x00 String System_control Fabrication_number Manufacturer name

ProductCode 0x01 String System_control Product_Code Manufacturerspecific device

identifier

MajorMinorRevision 0x02 String System_control Version Software version of

measuring system

ProductName 0x04 String System_control Product_Name Device name

SerialNumber 0x80 String System_control SerialNumber Serial number of

measuring system

ComponentNumber 0x81 Word Detector_para Classification = 0 Number of

measurands

BasisM 0x82 Word Modbus_conf Registernumber First register of the

measurands block

BasisS 0x83 Word Modbus_conf Registernumber First register of the

simulation data

BasisR 0x84 Word Modbus_conf Registernumber First register of the

reference material

data

Component1_Name 0x85 String Component_para Name Name of measured

component 1

Component1_

Range_Start

0x86 Float Meas_range_para Lower_meas_range Lower limit of output

range of measured

component 1

Component1_

Range_End

0x87 Float Meas_range_para Upper_meas_range Upper limit of output

range of measured

component 1

Component1_Unit 0x88 String Component_para Unit_name Unit of measured

component 1

Component2_Name 0x89 String Component_para Name Name of measured

component 2

Component2_

Range_Start

0x8A Float Meas_range_para Lower_meas_range Lower limit of output

range of measured

component 2

Component2_

Range_End

0x8B Float Meas_range_para Upper_meas_range Upper limit of output

range of measured

component 2

Component2_Unit 0x8C String Component_para Unit_name Unit of measured

component 2

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

51

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923