K-WANG

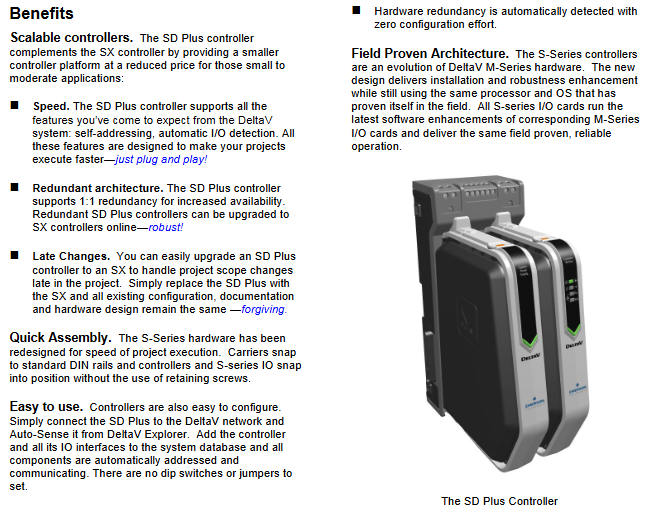

Emerson DeltaV SD Plus Controller

Emerson DeltaV SD Plus Controller

Basic Overview

The DeltaV SD Plus controller is a member of the S series controllers launched by Emerson Process Management. Its core function is to achieve communication and control between field devices and other nodes in the control network, while integrating the DeltaV I/O subsystem to simplify and speed up installation. It is compatible with the control strategies and configurations created by early DeltaV systems. On the basis of inheriting all the functions of M-series controllers, it adds support for CHARM based digital Marshalling, and the control language execution method can refer to the "Control Software" product data sheet. It is positioned as a small and medium-sized application scenario, complementary to the SX controller, and matches the control requirements of different processes through scalable design, while possessing high reliability and ease of use.

Core advantages

(1) Strong scalability and adaptability to flexible needs

Complementary hierarchical controllers: As a small and medium-sized controller of the S series, it is paired with the SX controller to form a "hierarchical selection" - SD Plus is suitable for small and medium-sized applications with a smaller platform size and lower cost; If there is a need for expansion in the later stages of the project (such as scope changes), the redundant SD Plus controller can be upgraded to an SX controller online, and the original configuration, documentation, and hardware design can be fully retained without the need for redevelopment.

Redundant architecture support: Supports 1:1 redundant configuration, improves system availability by adding backup controllers and power supplies, ensures stable and reliable redundant switching, and meets the high requirements for continuity in industrial scenarios.

I/O expansion capability: The local bus can connect up to 8 I/O carriers (8 cards per carrier), totaling 64 traditional I/O cards; Simultaneously supporting an additional 16 remote I/O units (traditional card type I/O); It is also compatible with fieldbus technologies such as Foundation fieldbus, Profibus DP, DeviceNet, AS-i, as well as serial interface cards and Ethernet I/O interfaces, to meet diverse device access needs.

(2) Quick assembly and ease of use

Tool free quick installation: The S series hardware adopts a brand new design, and the carrier can be snap mounted on a standard DIN rail. The controller and S series I/O can be inserted into place without fixing screws, greatly reducing cabinet assembly time and improving project execution efficiency.

Plug and play configuration: After connecting to the DeltaV network, the controller can be identified through the "Auto Sense" function of the DeltaV Explorer. The system will automatically add the controller and all its I/O interfaces to the database, and complete address allocation and communication configuration without setting DIP switches or jumpers, reducing the operational threshold.

Convenient programming and management: Developed control strategies using IEC-61131 standard programming techniques (functional blocks, sequential functional diagrams, structured text); The controller automatically generates diagnostic and event reports with timestamps for easy fault tracing; The control execution rate can be set according to the dynamic characteristics of the process (100ms~60s), and the controller will automatically adjust the scheduling; Support cross system referencing of any parameter by module name, without the need to pay attention to physical location; System clock synchronization ensures consistency of time driven events across the entire system.

(3) Mature and reliable architecture with digital grouping support

Stability verified on site: The S series controller is based on the DeltaV M series hardware evolution, using processors and operating systems verified on site, optimizing only installation convenience and robustness; All S-series I/O cards run the latest software enhanced version of M-series I/O cards, maintaining the same high reliability performance and reducing technical iteration risks.

Electronic Marshalling Design: Supports distributed I/O solutions based on CHARM - CHARM I/O cards (CIOCs) are connected through redundant Ethernet ports of the controller. A single controller can access up to 16 CIOCs, each providing 96 individually configurable signal types that can be flexibly installed in any position. Compared to traditional Marshalling I/O subsystems, it significantly reduces system footprint, simplifies system design and expansion.

Wireless and New I/O Support: Compatible with Wireless HART I/O cards, a single card can achieve redundant communication for up to 100 Wireless HART devices, ensuring high availability of wireless data; A single controller can support up to 16 Wireless HART I/O cards, meeting industrial wireless requirements.

(4) Adapt to harsh environments and comply with regulations

Wide environmental adaptability: Rated for G3 corrosive environments, operating temperature range -40 ° C~70 ° C, protection level up to IP20 (NEMA 12), can be directly installed in remote locations near process equipment, or can be paired with CHARM I/O cards for traditional central grouping cabinets, suitable for various installation scenarios.

Multi certification compliance: certified by CE (EMC complies with EN 61326-1:2006, LVD complies with EN 61010-1:2001) and CSA (CAN/CSA-C22.2 series standards); Compliant with NAMUR NE21 specifications; We have submitted certification applications for hazardous areas (ATEX/IECEx Zone 2, FM Class 1 Div 2) and ship applications (IACS E10, ABS, DNV, Lloyd's Register, etc.), and also support GOST Zone 2 hazardous area certification in Russia to meet the compliance requirements of different regions and industries.

Hardware specifications

Category specific parameters

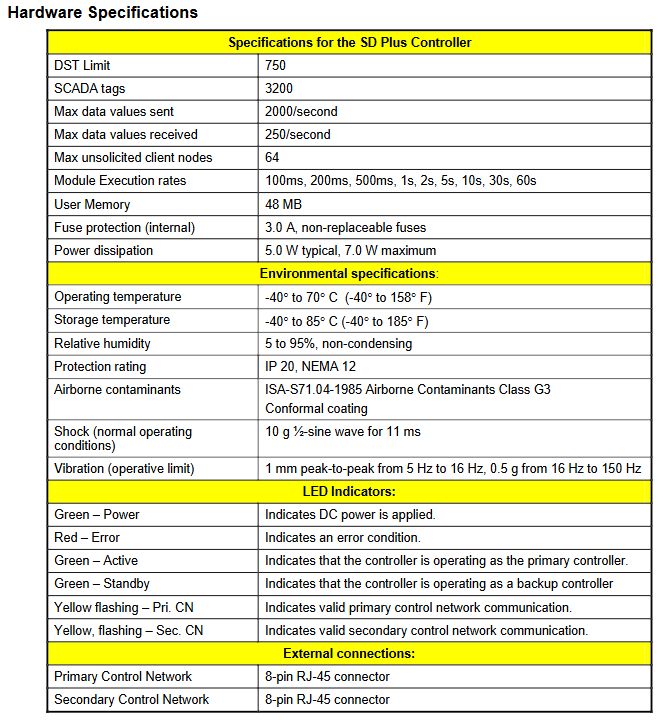

Performance indicator - DST (Device Signal Label) upper limit: 750

-SCADA tags: 3200

-Maximum data transmission capacity: 2000 pieces/second

-Maximum received data volume: 250 pieces/second

-Maximum number of active client nodes: 64

-Module execution rate: 100ms, 200ms, 500ms, 1s, 2s, 5s, 10s, 30s, 60s

-User memory: 48MB

Power and Protection - Power Supply: Powered by a dedicated system power supply through a Power/Controller carrier

-Internal fuse: 3.0A non replaceable fuse

-Power consumption: typical value of 5.0W, maximum value of 7.0W

Environmental parameters - Operating temperature: -40 ° C~70 ° C (-40 ° F~158 ° F)

-Storage temperature: -40 ° C~85 ° C (-40 ° F~185 ° F)

-Relative humidity: 5%~95% (without condensation)

-Air pollutants: Complies with ISA-S71.04-1985 G3 level and has a conformal coating

-Shock resistance (normal operation): 10g half sine wave, continuous for 11ms

-Vibration resistance (working limit): 1mm peak to peak value at 5Hz~16Hz, 0.5g at 16Hz~150Hz

LED indicator light - green (Power): indicates connection to DC power supply

-Red (Error): indicates the existence of an error state

-Green (Active): indicates that the controller is running as the main controller

-Green (Standby): indicates that the controller is running as a backup controller

-Yellow flashing (Pri. CN): indicates normal communication in the main control network

-Yellow flashing (Sec. CN): indicates that the backup control network communication is normal

External interface - Main control network: 8-pin RJ-45 connector

-Backup control network: 8-pin RJ-45 connector

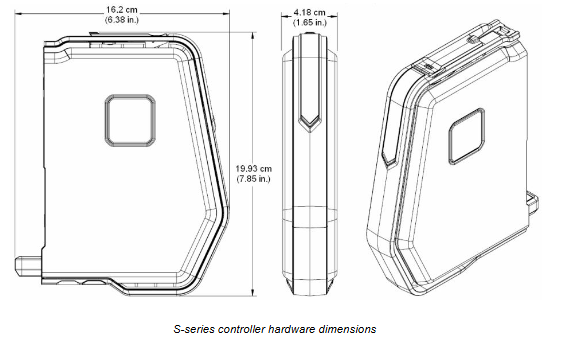

Dimensions 16.2cm (width) x 4.18cm (height) x 19.93cm (depth) (6.38in x 1.65in x 7.85in)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923