K-WANG

Emerson DeltaV M Series Virtual I/O Module 2 (VIM2)

Emerson DeltaV M Series Virtual I/O Module 2 (VIM2)

Basic Overview

The DeltaV M Series Virtual I/O Module 2 (VIM2) is an industrial grade I/O simulation and integration device launched by Emerson Process Management. It has two core functions: one is to work with MYNAH Technologies' MiMiMiC simulation software to achieve non-invasive simulation of DeltaV M Series I/O cards and digital bus field devices, supporting comprehensive testing of control strategies and system configurations; The second is to serve as an integrated platform for high-speed Ethernet I/O devices, driven by Modbus TCP/IP or Ethernet/IP protocols, to achieve signal reading and writing between the DeltaV system and devices (such as PLCs, motor control centers, weighing instruments, etc.) in the factory Ethernet I/O network. Its design is compatible with the DeltaV system architecture and can be seamlessly integrated into existing control networks.

Core advantages

(1) Non invasive DeltaV I/O simulation capability

Comprehensive simulation support: It can perform non-invasive simulation on all DeltaV M-series I/O modules (including traditional I/O, Foundation fieldbus, Profibus DP, DeviceNet, ASi bus, and serial cards) without modifying control strategies to complete DeltaV configuration testing; Simultaneously supporting simulation of all DeltaV digital buses and Foundation fieldbus function blocks, it can verify the effectiveness of fieldbus control configuration.

Efficient simulation performance: A single controller can simulate up to 64 DeltaV I/O modules, with fast and efficient simulation execution speed, which can make the DeltaV controller mistakenly believe that it is communicating with real I/O, ensuring that the test results are close to the actual operating scenario; It also supports I/O automatic detection and precise testing of controller load, providing data support for system optimization.

Supporting simulation software: It needs to be used in conjunction with MYNAH's MiMiC simulation software (software needs to be purchased separately). This software can provide dynamic simulation function for DeltaV system software acceptance testing and operator training - through simulation I/O and on-site equipment, simulate the real reaction of the process to the control system output signal, and the simulation I/O driver updates are synchronized with the MiMiC software version and can be quickly upgraded through the simulation network.

(2) Powerful Ethernet I/O integration capability

High capacity device access: A single VIM2 can simulate 4 DeltaV serial cards, supporting 128 serial card datasets for 32 network devices in single-mode configuration and 16 devices in redundant configuration. Ethernet communication is efficient and stable, meeting the large-scale equipment integration requirements of factories.

Flexible network configuration: supports user-defined IP addresses and can adapt to almost all factory network architectures (requiring the same IP subnet as Ethernet I/O devices); Simultaneously supporting 1:1 redundant configuration - by adding a second VIM2 to form a redundant pair, simulating 4 pairs of redundant DeltaV serial cards, the main and backup cards automatically switch (consistent with the switching logic of DeltaV serial cards), and the operator can obtain switching notifications through the display interface or manually control the switching in DeltaV Diagnostics.

Multi protocol compatibility: Supports two mainstream industrial Ethernet protocols and adapts to different device types:

Modbus TCP/IP: As a master, it supports 9 types of function codes, including reading coil status (Code1) and writing multiple registers (Code16). It can function as both a master and slave (up to 32 slave stations or 16 master stations+16 slave stations are supported in single-mode mode; only the master station is supported in redundant mode, up to 16 slave stations are supported).

Ethernet/IP: As a scanner (initiator), it supports CIP protocol functions such as UCMM (connectionless) messages, Class 3 (connected) messages, and Class 1 (I/O) connections, and is compatible with the Ethernet/IP specifications defined by the Open DeviceNet Vendor Association.

(3) Usability and system compatibility

Seamless DeltaV Integration: The VIM2 is recognized by the DeltaV M series controller as four DeltaV serial cards. During debugging, serial dataset configuration can be completed through the DeltaV Explorer (consistent with conventional serial card configuration). Ethernet I/O signals can be directly used for the DeltaV control module, displayed on the DeltaV Operate graphical interface, or stored in the DeltaV historical database without the need for additional interface development.

Intuitive configuration tool: Comes with the VIMNet Explorer application (integrated with DeltaV v12 and above, or provided with MYNAH driver), supports "plug and play" configuration - completes VIM2 debugging, primary and backup redundancy settings, and Ethernet I/O network parameter configuration (such as IP address, subnet mask, gateway, device node address, etc.) through graphical drag and drop operations. It also supports driver firmware upgrades and type replacements (only supports loading one Ethernet I/O driver at a time).

Modular and flexible installation: Adopting the same installation method as the DeltaV controller, it can be installed in the controller slot of a 2-wide horizontal carrier or a 4-wide vertical carrier (located on the left side of the DeltaV controller), using standard DeltaV power supply. The design is durable and can operate stably for a long time.

Details of Function Implementation

(1) Implementation of I/O simulation function

Hardware coordination: The VIM2 hardware preloads the I/O simulation driver and communicates with the MiMiC software through the simulation network. After disconnecting the real I/O card from the control system, the MiMiC driver directly writes simulation signals to the I/O subsystem of the DeltaV controller.

Simulation data management: A single simulated process controller corresponds to one MiMiC dataset, and a MiMiMiC server can support up to 32 datasets (ports). Each dataset can accommodate 4000 MiMiMiC simulation labels, meeting the requirements of large-scale process simulation.

Technical Support: Technical support for I/O simulation drivers and MiMiC software is provided by MYNAH Technologies and requires separate contact with the supplier for service.

(2) Implementation of Ethernet I/O Integration Function

Drivers and configurations: Ethernet I/O drivers (such as Modbus TCP/IP master drivers, Ethernet/IP scanner drivers, etc.) need to be purchased separately from MYNAH. After loading the drivers, the DeltaV controller can automatically detect the debugged VIM2 (serial cards identified as slots 57-60 or 61-64 in single-mode configuration, and redundant pairs identified as slots 57-64 in redundant configuration).

Redundancy mechanism: The redundant VIM2 needs to be installed on independent 2-wide carriers, equipped with independent power supplies, and monitored for the status of the main and backup devices through dedicated redundant link cables (included in the redundancy kit) - the main VIM2 continuously communicates with industrial Ethernet devices, while the backup VIM2 sends intermittent signals to maintain communication integrity and ensure uninterrupted switching between the main and backup devices.

Configuration tool requirements: VIMNet Explorer needs to run on a workstation connected to the Ethernet I/O network (which can be a DeltaV workstation with a third network card or a non DeltaV workstation), support Windows XP/7 system, and complete connection configuration through the RJ45 Ethernet interface at the bottom of VIM2.

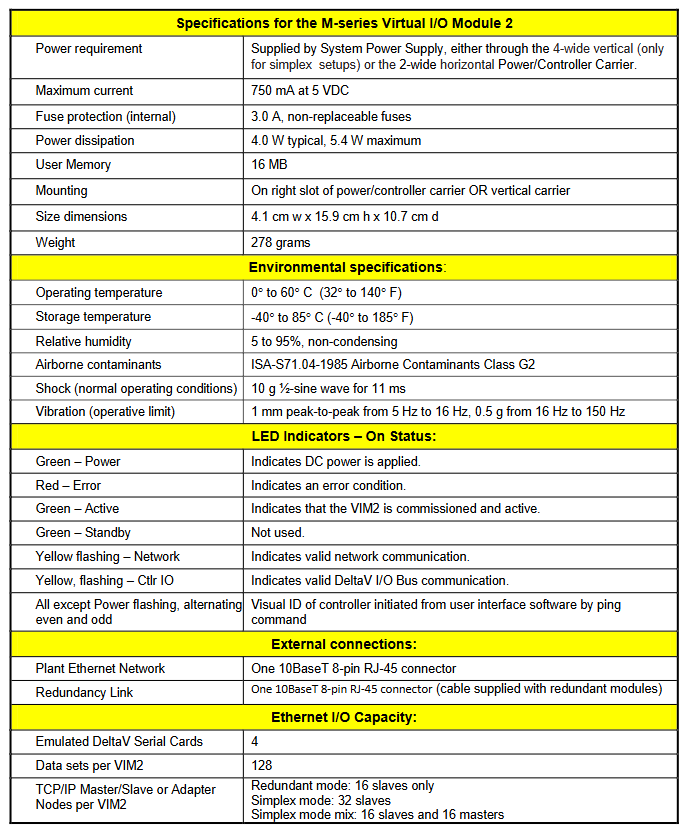

Hardware specifications

Category specific parameters

The power requirement is supplied by the DeltaV system power supply, supporting 2-wide horizontal carriers or 4-wide vertical carriers (single-mode configuration only)

Electrical protection built-in 3.0A non replaceable fuse, maximum current 750mA (5VDC)

Typical power consumption of 4.0W, maximum value of 5.4W

Storage and Size: User Memory 16MB; Size: 4.1cm (width) x 15.9cm (height) x 10.7cm (depth), Weight: 278g

Installation method: Install in the right slot (horizontal carrier) or vertical carrier of the power/controller carrier

Environmental parameters: Operating temperature: 0 ° C~60 ° C (32 ° F~140 ° F), Storage temperature: -40 ° C~85 ° C (-40 ° F~185 ° F); Relative humidity ranging from 5% to 95% (without condensation); The air pollutant level complies with ISA-S71.04-1985 G2 level; Shock resistance (normal operation): 10g half sine wave, continuous for 11ms; Vibration resistance (working limit): 1mm peak to peak value at 5Hz~16Hz, 0.5g at 16Hz~150Hz

LED indicator light - green (power): indicates connection to DC power supply

-Red (Error): Indicates the existence of an error status

-Green (Active): indicates that VIM2 has been debugged and is in an active state

-Green (Standby): Not used

-Yellow flashing (Network): indicates normal network communication

-Yellow flashing (Ctlr IO): indicates that DeltaV I/O bus communication is normal

-Alternating flashing (parity) except for the power light: device recognition triggered by the ping command on the user interface software

External Interface - Factory Ethernet: 1 10BaseT 8-pin RJ-45 connector

-Redundant link: 1 10BaseT 8-pin RJ-45 connector (redundant kit includes dedicated cable)

Ethernet I/O Capacity - Analog DeltaV Serial Card: 4

-Number of datasets: 128 per unit

-Number of device nodes: 32 single mode slave stations (or 16 master+16 slave stations), redundant 16 slave stations

DeltaV Authorization and Configuration Rules

DST counting rule: The DeltaV software authorization requirement (DST counting) for the VIM2 register is consistent with the serial card register - a single DeltaV serial card dataset can contain up to 100 values (Boolean, 8-bit/16 bit values), and if it is a floating-point or 32-bit value, it can contain up to 50 values; If a single dataset is referenced by only one module, it is counted as one DST; If referenced by multiple modules, the DST count is equal to the number of referenced modules.

DST type differentiation: The numerical count used to control the function block is "Control DST", and the numerical count used only for graphic display or historical data acquisition is SCADA value, not included in DST count.

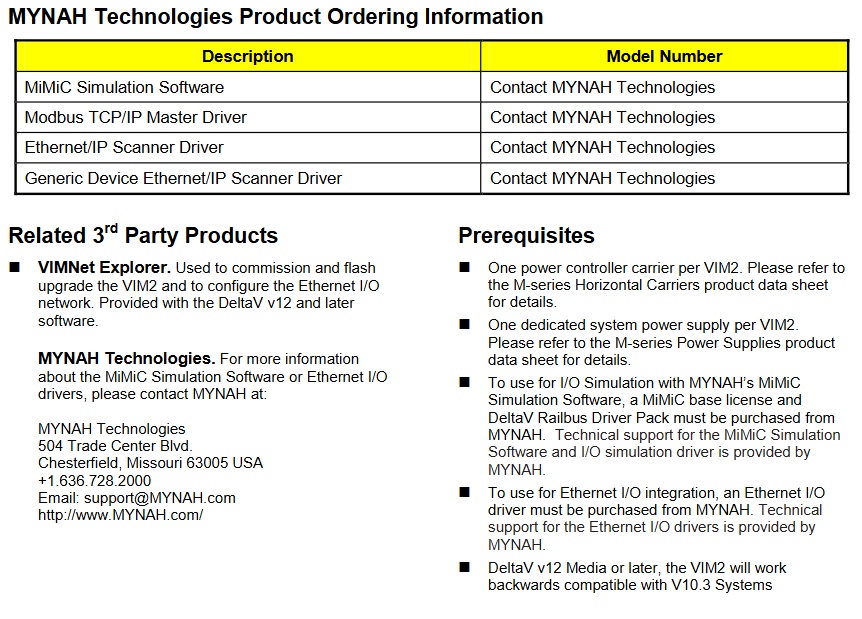

Ordering and matching requirements

(1) VIM2 and redundant package

M-Series Virtual I/O Module 2 (Single Mode) VE4026 Single VIM2 Device, requires separate carrier and power supply

Redundant M-series Virtual I/O Module 2 VE4027 includes 2 VIM2 devices and 1 redundant link cable

(2) Supporting products that need to be purchased separately

MiMiC simulation software MYNAH Technologies is used for I/O simulation and requires the purchase of both MiMiC basic license and DeltaV Railbus driver package

Modbus TCP/IP Master Driver MYNAH Technologies for Ethernet I/O Integration (Modbus Protocol)

Ethernet/IP scanner driver MYNAH Technologies for Ethernet I/O integration (Ethernet/IP protocol)

Universal Ethernet/IP scanner driver MYNAH Technologies adapts to non-standard Ethernet/IP devices

(3) Installation and software prerequisites

Hardware support: Each VIM2 requires one power/controller carrier (refer to the M-series horizontal carrier data sheet) and one dedicated DeltaV system power supply (refer to the M-series power supply data sheet).

Software version: Supports DeltaV v10.3 and above, and recommends using DeltaV v12 and above (VIMNet Explorer tool provided with this version of software).

Technical Support: The VIM2 hardware is supported by Emerson, while the technical support for MiMiC simulation software and Ethernet I/O drivers is provided by MYNAH Technologies

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923