+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

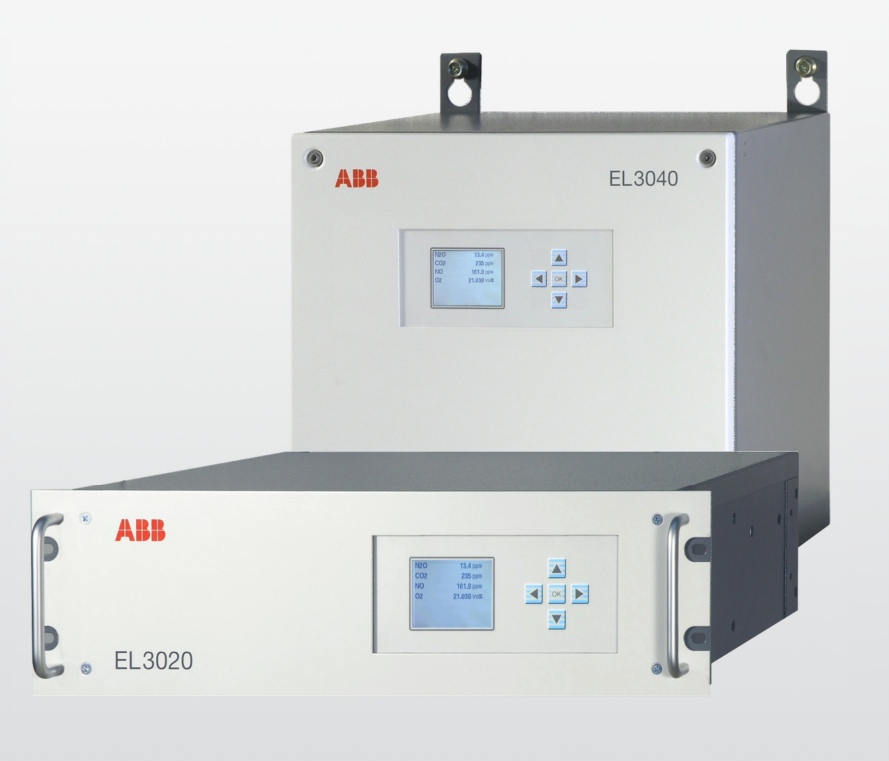

ABB EasyLine EL3000 Series Continuous gas analyzers

ABB EasyLine EL3000 Series Continuous gas analyzers

ABB EasyLine EL3000 Series Continuous gas analyzers

Measurement made easy

So smart, they're simple

—

A wide variety of measurement technology

• Detectors for multiple process and emission monitoring

applications

• Up to five sample components per device

• Suited for measuring flammable gases

• Version in IP rating II 3G for measuring non-flammable gases

• Performance-tested for emission monitoring in accordance

with EN 15267

• QAL3 monitoring in accordance with EN 14181 (optional)

—

Straightforward handling

• Automatic calibration including control of pump and valves

• Simplified calibration with air or integral calibration cells

eliminating the need for test gas cylinders

• Self-monitoring function indicates when maintenance is

required

—

Application-oriented design

• Housing design for 19-inch rack mounting or wall mounting

• Integrated gas feed as an option in model EL3020

• Ethernet, Modbus and PROFIBUS interfaces

• Configurable analog outputs and digital inputs and outputs

—

User-friendly operation

• Simple user interface

• Clear-text status messages

• Configuration of seldom required functions with

configuration software

Overview of the gas analyzers

Measuring technology (analyzers)

The following analyzers are available for selection:

• Uras26 infrared photometer for the measurement of infrared active gas components, e.g. CO, NO, SO2,

• Ultraviolet photometer Limas23 to measure NO, NO2 and SO2.

• Magnos206 oxygen analyzer for the measurement of

O2 in process gas or in N2,

• Magnos28 oxygen analyzer for the measurement of O2 in pro cess gas or in N2,

• Magnos27 oxygen analyzer for the measurement of O2 in flue

gas or in N2,

• The ZO23 trace oxygen analyzer is used for the measurement

of O2 in pure gases (N2, CO2, Ar).

• Caldos27 thermal conductivity analyzer for the measurement

of binary gas mixtures with different thermal conductivity, e.g.

Ar in O2, H2 in Ar, CH4 in N2

• Fidas24 flame-ionization detector for the measurement of hy drocarbons

• Electrochemical oxygen sensor for the measurement of O2

Magnos206 and Magnos28 can also be used in combination with

Uras26 or Limas23.

Magnos27 and Caldos27 can also be used in combination with

Uras26.

Magnos28 can also be used in combination with Magnos28.

Magnos28 can also be used in combination with Caldos27.

Caldos27 can also be used in combination with Caldos27.

Fidas24 and ZO23 cannot be used in combination with one of the

other analyzers.

The electrochemical oxygen sensor can only be used in combina tion with Uras26 or Limas23. Two electrochemical oxygen sen sors can be used in combination with Uras26 with separate gas

paths (only in model EL3020).

Each analyzer has one physical measurement range per sample

component. A section of the physical measurement range can be

mapped to the current output (analog output) by on-site config uration.

Calibration is always executed in the physical measurement

range. The permissible measurement range limits are given by

the specification of the smallest and largest measurement

ranges for the individual analyzers.

A total of up to five measurement components can be measured

with one gas analyzer.

Calibration

Calibration can be performed automatically or manually or exter nally controlled via the Modbus.

Automatic calibration – for all sample components together – is

normally started on a cyclically time-controlled basis; it can also

be started by an external control signal or via the Modbus as well

as manually on the display and operator control unit of the gas

analyzer.

Normally, simplified calibration methods with the built-in calibra tion cells or the so-called single-point calibration are used for au tomatic calibration. If calibration with test gases is required the

control of solenoid valves for switching on five test gases, zero

gas and sample gas via digital outputs can be configured.

Concept of operation

The functions required in normal operation are operated and con figured directly on the gas analyzer.

The device functions which are only seldom required, e.g. during

commissioning, are configured offline using the ECT configura tion program (‘EasyLine Configuration Tool’ on the enclosed DVD ROM) and then loaded into the gas analyzer.

QAL3 monitoring

The gas analyzer can optionally be equipped with QAL3 monitor ing, used to fulfill the requirements in accordance with EN 14181

for the storage and analysis of device adjustment data. The QAL3

monitoring option features the following functions:

• Automatic acquisition, verification and documentation of drift

and precision at zero and reference points

• Reporting via CUSUM and Shewhart control charts

• QAL3 data storage in the gas analyzer (maximum 1 year)

• QAL3 data display and read-out as well as parameter setting

via web browser

• Status messages on deviations beyond requirements

• Data export for further processing with spreadsheet programs

Electrical interfaces

The electrical interfaces for the output of measured values and

communication with external systems include

• The integrated Ethernet-10/100BASE-T interface for

– device configuration using the ECT configuration program

– QAL3 data transfer if the QAL3 monitoring option is integrated in the gas analyzer

– Data transmission using the Modbus TCP/IP protocol

(measured values, status signals, control signals)

as well as the integrated I/O modules depending on the functional range and order

• Profibus module with one RS485 and one MBP interface (also

in accordance with VDI 4201 Part 2),

• Modbus module with one RS232 and one RS485 interface (also

in accordance with VDI 4201 Part 3),

• Digital I/O module with four digital inputs and four digital outputs,

• 2-way analog output module with two analog outputs,

• 4-way analog output module with four analog outputs.

Integral gas feed

The integral gas feed (optional in model EL3020) is available in

two versions. It includes

• either the solenoid valve, pump, coarse filter, capillary tube

and flow sensor modules

• or the flow sensor module.

Housing design

The EL3020 gas analyzer model features a 19-inch housing with

3 height units (4 height units with Magnos27) and IP rating IP20

(IP40 in version for emissions monitoring).

The housing for the EL3040 gas analyzer model is designed as

wall-mount housing with degree of protection IP65.

Measurement principle

Non-dispersive infrared absorption

Photometer with 1 or 2 beam paths (gas paths) to measure up to

4 sample components

Sample components and measurement ranges

Sample components and smallest measurement ranges

sample component Smallest meas. range

CO 0…100 ppm

CO2 0…100 ppm

NO 0…150 ppm

SO2 0…100 ppm

N2O 0…100 ppm

CH4 0…100 ppm

Measurement range quantity

2 measurement ranges

Measurement range limits

Smallest meas. range Largest measurement range

0…100 ppm (NO: 0…150 ppm) 0…500 ppm (NO: 0…750 ppm)

0…200 ppm 0…1000 ppm

0…600 ppm 0…3000 ppm

0…2000 ppm 0…10000 ppm

0…0.6 vol.% 0…3 vol.%

0…2 vol.% 0…10 vol.%

0…6 vol.% 0…30 vol.%

0…20 vol.% 0…100 vol.%

An individual measurement range within the limits shown in the

table can be factory-set on special order.

Measurement ranges are freely adjustable within the limits shown

in the table.

Measurement ranges should not be set within ignition limits.

Version for use in air separation units

Only for binary gas mixtures consisting of the sample component

in Ar, N2 or O2

sample component Smallest/greatest measuring

range

CO 0…10 ppm / 0…50 ppm

CO2 0…5 ppm / 0…25 ppm

N2O 0…10 ppm / 0…50 ppm

CH4 0…20 ppm / 0…100 ppm

Other than the data valid for the standard version the following

data apply for this version (in % of the smallest measurement

range shown in the table):

Zero point drift: ≤ 1.5 % per day

Sensitivity drift: ≤ 1 % per week

Output signal fluctuation (2 σ): ≤ 0.5 % at T90 = 15 s

Temperature effect: ≤ 2 % per 10 °C

Stability

The following data only applies if all the influence variables (e.g.

flow, temperature and air pressure) are constant. They relate to

the smallest measurement range.

Linearity deviation

≤ 1 % of span

Repeatability

≤ 0.5 % of span

Zero point drift

≤ 1 % of span per week

Sensitivity drift

≤ 1 % of measured value per week

Output fluctuation (2 σ)

≤ 0.2 % of span at electronic T90 time (static/dynamic) = 5/0 sec

Detection limit (4 σ)

≤ 0.4 % of span at electronic T90 time (static/dynamic) = 5/0 sec

Influence effects

Flow effect

Flow rate in the 20…100 l/h range:

Associated gas effect/cross sensitivity

The knowledge of the sample gas composition is necessary for

the analyzer configuration. Selectivation measures to reduce the

associated gas effect (options): incorporation of interference fil ters or filter cells, internal electronic cross-sensitivity or carrier

gas correction for one sample component by other sample com ponents measured with the gas analyzer.

Temperature effect

Ambient temperature in the permissible range

– at zero point: ≤ 2 % of span per 10 °C

– on the sensitivity with thermostat effect:

≤ 3 % of the measured value per 10 °C

– on the sensitivity with thermostat effect (optional): ≤ 2 % of

the measured value per 10 °C

thermostat temperature = 55 °C

Air pressure effect

– at the zero point: no effect

– On sensitivity with pressure correction using an integrated

pressure sensor: ≤ 0.2 % of the measured value per 1 % of air

pressure change

The pressure sensor is located in the sample gas path if hoses are

used as the internal gas lines. If stainless-steel tubing is used for

internal gas lines the pressure sensor is routed to the outside via

a hose.

Power supply effect

Voltage and frequency in the permissible range; no effect

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

51

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923