K-WANG

Honeywell Enhanced Micro TDC 3000 Control System

Honeywell Enhanced Micro TDC 3000 Control System

Product Infrastructure

Core positioning: Enhanced Micro TDC 3000 is a compact industrial control system of the TDC 3000X family, designed specifically for small and medium-sized process industries, supporting centralized and distributed control, balancing control accuracy and deployment flexibility.

hardware architecture

Cabinet design: Dual cabinets (Tower # 1 and Tower # 2), each cabinet is a 4-node multinode module, supporting up to 8 nodes for expansion

Cabinet size: Single cabinet 72cm (height) x 32cm (width) x 58cm (depth), weight 45kg/unit

Core processor: The entire node is equipped with K2LCN processor, which supports hardware level fault diagnosis

Environment and Certification

|Category | Parameter Specifications|

|Working temperature | 0 ℃~45 ℃ (Class C office environment)|

|Storage temperature | -10 ℃~70 ℃|

|Humidity range | 10%~80% (no condensation), temperature change rate<6%/hour|

|Vibration/impact | 5-22Hz 0.254mm displacement; 22-500Hz 0.25g acceleration|

|Certification Standards | CE (89/366/EEC EMC Directive), UL 508, Class I Div 2 Hazardous Areas|

Core Component Details

1. Four core modules

Module type, core configuration, key parameters, functional positioning

Universal Station (US) 6MW memory, dual 150MB Bernoulli cartridge drives support operator/engineer keyboards, optional touch screen/trackball human-machine interaction, system configuration, process monitoring

Application module (AM) 4/8MW memory, supports CL language control strategy execution, custom calculation, data processing core control unit

Network interface (NIM) UCN address 1 (primary)/2 (redundant), RS-485 interface connected to APM controller, supporting UCN A/B dual bus process bus communication gateway

History module (HM) 875MB hard drive, 3MW memory storage system software, configuration data, historical trend data storage, and log management

2. Expansion modules and peripherals

extension module

EPLCG (Enhanced PLC Gateway): connects one or more PLCs and supports RS-232 communication

CG (Computer Gateway): connects to the host and supports redundant communication paths

Redundant NIM: Provides backup communication paths to improve reliability

LCN Upgrade Kit: Connect the system to a standard LCN network and support multi cabinet expansion

Peripheral support

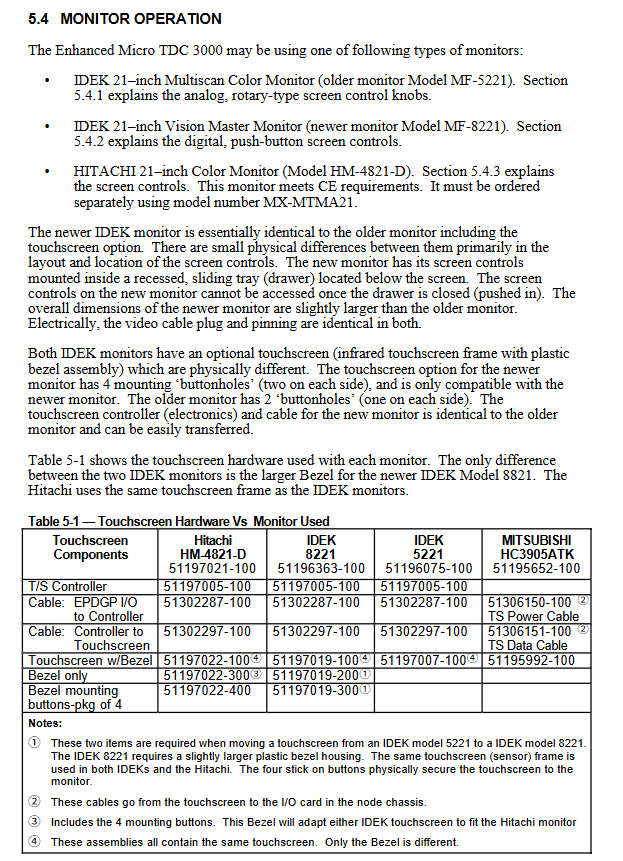

Display: 20 inches (weight 29kg), 21 inches IDEK/HITACHI (weight 33-34kg), supporting VGA/MACII signals

Printer: ASPI-41, supports self checking and diagnostic printing, powered by 120/240VAC

Input devices: Operator membrane keyboard (chemically resistant), Engineer keyboard (hot swappable), Touch screen/trackball

Communication and Integration

1. Bus system

Bus type communication specifications, application scenarios, topology limitations

TPLCN RS-485,5Mbit/s, Token Transfer Protocol Cabinet Node Communication Standard Cable 1.5 meters, optional 10 meter long cable

UCN coaxial cable, connected to APM controller process control signal transmission drop cable with a maximum length of 15 meters, requires terminal resistance

Expansion bus RS-232/485, PROFIBUS, DeviceNet third-party device integration is achieved through gateway modules, supporting multiple master stations

2. Network configuration restrictions

Each C200 controller supports a maximum of 64 I/O units

Each downlink CNI can connect up to 8 uplink devices (CNI/gateway)

RIOM-A gateway supports a maximum of 8 I/O modules

DeviceNet network has a maximum of 64 devices with speeds of 125/250/500KBps

PROFIBUS network has a maximum of 126 slave stations, with speeds ranging from 9.6K to 12Mbps

Power supply and physical specifications

Power supply parameters

|Equipment | Input voltage | Typical power consumption | Maximum current|

|Tower # 1 (including US/AM/NIM) | 120VAC | 266W | 10A (peak)|

|Tower # 2 (including HM) | 120VAC | 185W | 6.5A (peak)|

|20 inch monitor | 120VAC | 79W | 1.14A|

|21 inch monitor | 120VAC | 83W | 1.5A|

|ASPI-41 printer | 120VAC | 210W | 1.75A|

Power supply tolerance: 120VAC ± 15%, 240VAC ± 10%, frequency 47-63Hz

Redundant power supply: supports dual power hot backup and uninterrupted switching

Physical installation requirements

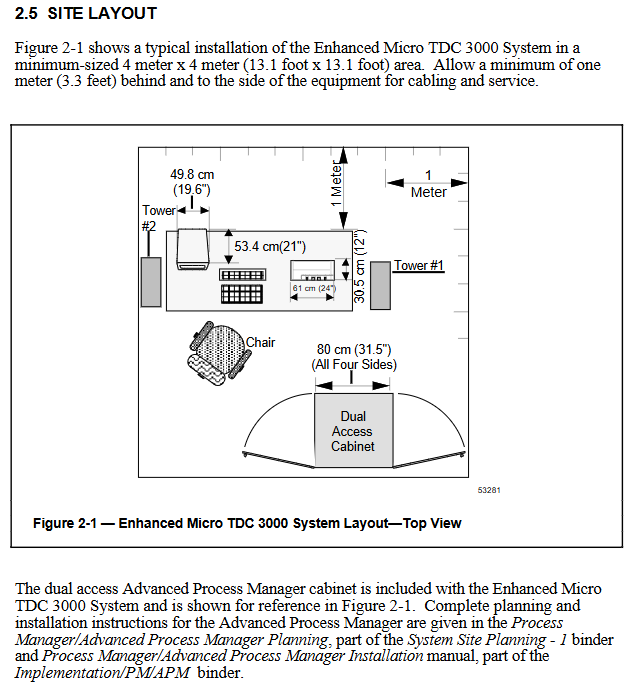

Installation space: minimum 4m x 4m, with 1 meter of maintenance space reserved around the cabinet

Cabinet spacing: Standard cables up to 33 inches (84cm), long cables can be selected up to 10 meters

Grounding requirements: protective grounding (PE) ≥ 10AWG, EMC grounding 4AWG, grounding resistance ≤ 4 Ω

Environmental restrictions: Outdoor installation is prohibited, hazardous areas must comply with Class I Div 2 wiring specifications

Functional characteristics

Control and Data Processing

Control Algorithm: Supports PID regulation, logic control, sequence control, and custom CL language programs

Data acquisition: analog quantity (4-20mA/± 10V), digital quantity (24VDC/120/220V AC), temperature (thermocouple/RTD)

Storage capacity: HM supports 875MB of historical data storage, including event logs, alarm records, and operation records

Custom features: Free Format Logs reports, graphical screen editing, button configuration

Operation and Safety

Permission classification: Operator (basic monitoring), Administrator (parameter modification), Engineer (system configuration)

Password protection: default password "TDC3000 SUPV" (administrator), "TDC3000 ENGR" (engineer), supports custom modification

Display functions: trend analysis, alarm summary, detailed point display, system status monitoring

Safety protection: intrinsic safety wiring isolation, short circuit protection, overvoltage protection, ESD anti-static measures

Maintenance and Diagnosis

Fault indication: LED status light (power OK, error, fan alarm), 7-segment digital tube node address display

Removable Units (ORUs): power module, I/O board, communication module, air filter (51201201-600), printer print head/ribbon

Hot swappable support: Non hazardous areas can plug and unplug modules with power on, and the system automatically recognizes them

Diagnostic tools: HVTS hardware verification testing system, IOTOOL calibration tool, NTOOL network monitoring

Deployment and operation process

Installation process: Site preparation → Cabinet positioning → Cable connection (power/communication/process) → Grounding → Power on testing → System configuration

System startup: HM automatic boot → US loading operating system → configuring network parameters → loading control strategy → startup process monitoring

Daily operation: Call the display screen through the operator keyboard → Monitor process parameters → Handle alarms → Generate reports

Maintenance cycle: Air filter cleaning (30-180 days, depending on the environment), cartridge driver cleaning, printer maintenance

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923