K-WANG

Honeywell IPC 620-06 Programmable Controller

Honeywell IPC 620-06 Programmable Controller

Product Infrastructure

Core positioning: IPC 620-06 is the core model of the 620 series programmable controller, designed specifically for industrial automation scenarios, with functions such as logic control, data acquisition, and equipment linkage, suitable for centralized or distributed control needs of small and medium-sized industrial devices.

hardware architecture

Rack type: processor rack (full rack: 620-0090/0091, 8 I/O slots; Half rack: 620-0092/0093, 4 I/O slots), I/O rack (full rack: 621-9990/9992, 12 I/O slots; Half rack: 621-9991, 6 I/O slots)

Installation specifications: Full rack compatible with 19 inch instrument rack (8 inches deep), half rack suitable for narrow spaces (10 inches wide), supports bidirectional installation of rack/panel

Core processor: Motorola 68B09E microprocessor, paired with 2K memory, supports EPROM optional expansion (27128 model)

Environment and Power Supply

|Category | Specification Parameters|

|Power supply type | AC (115/230VAC ± 10%), DC (24VDC ± 20%)|

|Frequency range | 47-63Hz|

|Working temperature | Industrial standard environment (unspecified, default 0-60 ℃)|

|Data backup | 3V lithium battery (AA lithium dry battery), backup for ≥ 6 months|

|Protective features | Rack mounted design, dust-proof modules, and anti misoperation terminal blocks|

Core Component Details

1. Processor module (PM: 620-0636)

Core configuration: 2K memory, including 768 bit output status table (0-191 actual I/O, 192-767 control relay), 256 16 bit registers (4096-4351)

Operation control: 3-position key switch (Program/Disable/RUN/Program), 4 status LEDs

RUN LED: Scan running indicator

FORCE LED: Command Force Status Indication

PASS LED: self-test pass indicator

BATTERY PASS LED: Battery normal indication

Backup and Expansion: Built in lithium battery compartment (front replaceable), supports EPROM program backup (U32 slot)

Communication interface: 9-pin D-type connector (RS4229600 Baud), connected to programming terminal/Loader

2. Power module (PSM)

Divided into processor rack power supply and I/O rack power supply, the core parameters are as follows:

Module Model Applicable Scenarios Input Specifications Output Specifications Key Features

620-0041 processor rack 115/230VAC+5VDC (8A), ± 15VDC (600mA) 95VA power consumption, 2A/1A fuse

620-0083 processor rack 85-132/170-250VAC+5VDC (15A), ± 15VDC (1.16A) 90W total power, switch selection

620-0046 processor full rack 20-28VDC+5VDC (8A), ± 15VDC (600mA) 96VA power consumption, 8A fuse

621-9932 I/O rack/processor half rack 20-28VDC+5VDC (8A), ± 15VDC (600mA) 96VA power consumption, 40A cold start current

621-9933 I/O rack 85-132/170-250VAC+5VDC (10-15A), ± 15VDC (1.3-2A) 110VA power consumption, 4A/2A fuse

621-9934 I/O rack/processor half rack 115/230VAC+5VDC (8A), ± 15VDC (600mA) single width module, 2A/1A fuse

3. I/O system

Rack configuration: The full rack supports 12 I/O modules, 1 PIOM, and 1 PSM; Half rack supports 6 I/O modules+1 PIOM+1 PSM

Module type:

Digital I/O: 8/16/32 points, voltage covers 5/12/24/48/115/230VAC/DC, supports Sink/Source type

Analog I/O: 8-point 4-20mA/0-10V input, 4-point 4-20mA/0-10V output, isolated design

Special features: thermocouple/mV input, high-speed counter, pulse input, ASCII communication, absolute encoder interface

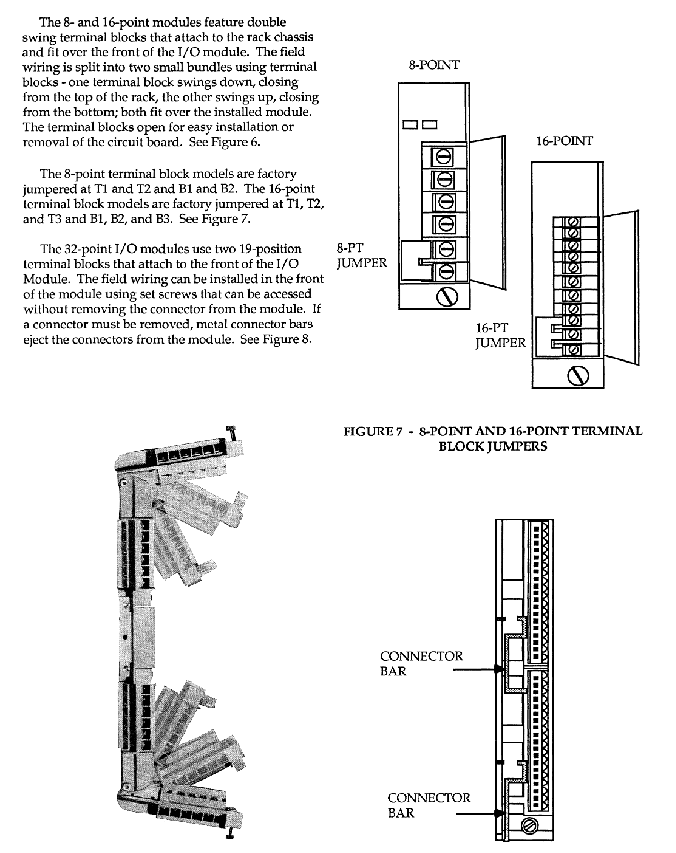

Terminal block design: The 8/16 point module adopts dual swing terminal blocks, and the 32 point module adopts dual 19 position terminal blocks, supporting on-site wiring with screw fixation

4. Expansion module

Module type, model, function positioning, key parameters

Control Network Module (CNM) 620-0038: Multiple PLCs can be interconnected up to 8 units, with 32/64 bit I/O status transmission

Communication Interface Module (CIM) 620-0043/0044/0048/0052 supports Modbus RTU, DMCS/ABC protocols for serial communication

Hiway Interface Module (HIM) - connects to TDC-3000 system to provide access interface for upper level devices

Operator Panel Interface (OPI) - Connect button/keyboard display single coaxial cable transmission

I/O Expansion Module (IOEM) 620-0053 Expansion I/O Rack 50 Pin D Connector, daisy chain topology

Parallel I/O module (PIOM) 621-9937 I/O rack controls 2 50 pin interfaces, with DIP switches configured for address configuration

Communication and Network

Parallel I/O link

Topology: daisy chain, processor rack IOEM → I/O rack PIOM → expansion I/O rack PIOM

Transmission distance: maximum 50 feet (multi conductor cable)

Capacity limit: Up to 2 external I/O racks, total system I/O points ≤ 192

Control Network

Transmission medium: twisted pair cable (up to 4000 feet), dual axis cable (up to 8000 feet)

Communication characteristics: High speed peer-to-peer communication, each PLC can transmit 32/64 bit I/O status and receive 256 bit I/O status

Response time: 8 PLCs with full service ≤ 18ms

Topology structure: multi-point configuration, supporting interconnection of 8 620 series PLCs

serial communication

Protocol support: CIM module provides Modbus RTU (620-0044), Honeywell DMCS (620-0048), ABC (620-0052) protocols

Interface standard: RS422/RS232, supports communication with 627 LOS and third-party smart devices

Operation mode and programming features

Three operation modes | Mode | Core function | Status indication | Key operation|

|Program | Program editing/uploading/downloading, do not scan program | RUN LED off | Clear/modify program, force command|

|DISABLE | Execute program without updating actual output | RUN LED stays on | Program testing, output status monitoring|

|RUN/PROGRAMME | switchable RUN/PROGRAMME, default RUN | RUN LED always on | normal control, online programming (ARMP)|

Programming Core Features

Instruction set: covering relay logic (NO/NC contacts, output, latch/unlock), timer/counter (ON/OFF delay, hold type), arithmetic operations (addition, subtraction, multiplication, division, comparison), data operations (Bring In/Send Out, PUSH/PULL), sequence control, etc., with a total of 30+instructions and execution time of 5.49-506.30 microseconds

ARMP online programming: firmware version ≥ 48 supported, program modification during operation, scan time increase ≤ 20ms, online programming DIP switch needs to be enabled

EPROM backup: supports writing RAM programs into EPROM, automatically restores when powered on (cold start/low battery), RAM programs cannot be modified

Mandatory function: Supports command enforcement, FORCE LED indication, requires activation through processor DIP switch

Data backup and recovery

Lithium battery backup: 3V AA lithium dry battery, backup memory/register data for ≥ 6 months, front replaceable

Cold start recovery: EPROM program → RAM, output status table reset, register data recovery

Hot start recovery: RAM program retention, output/register data retention, jump table not transferred

Diagnosis and safety features

Diagnostic function

Power on self-test (POST): microprocessor, ROM checksum, RAM read-write, I/O bus testing

Program checksum: Calculate the checksum for every 24 words scanned during operation, and compare it with the initial value to detect program errors

Online check: Check ISS instruction position, EOM instruction integrity, scan timeout (150-200ms)

Fault monitoring: The system status table (address 2413-2432) records scan loss, battery status, I/O fault count, and address

safety protection

Output fault handling: configured through PIOM DIP switch, output reset or hold in case of fault

Power protection: AC power undervoltage detection (115VAC ≤ 83V, 230VAC ≤ 166V), DC power undervoltage detection (24VDC ≤ 19V)

Static protection: Module insertion and removal require anti-static measures, as RAM data may be lost when the module is removed

Lithium battery safety: Do not charge, burn, short circuit, avoid high temperature storage

Address configuration and deployment

Address configuration rules

Rack start address: set through PIOM SW1, range 0-184, subsequent rack start address=previous rack end address+1

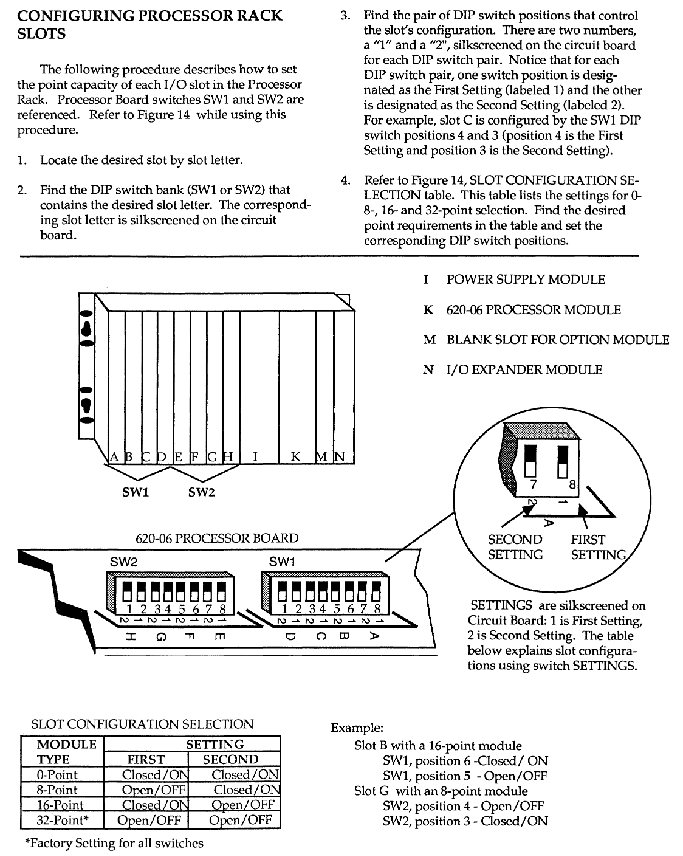

Slot address: Set through PIOM SW3/SW4/SW5, each slot can be configured with 0/8/16/32 points

Address example: Processor rack (0-127) → I/O rack # 1 (128-191), supports 8/16/32 point module hybrid configuration

Deployment requirements

Installation space: Reserved maintenance space around the full rack, half rack suitable for narrow environments such as motor control centers

Grounding requirements: The protective grounding and signal grounding should be separated, and the grounding resistance should be ≤ 4 Ω

Cable specification: Control Network uses shielded twisted pair cables, parallel I/O cable length ≤ 50 feet

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923