K-WANG

Honeywell Experion PKS Series C I/O

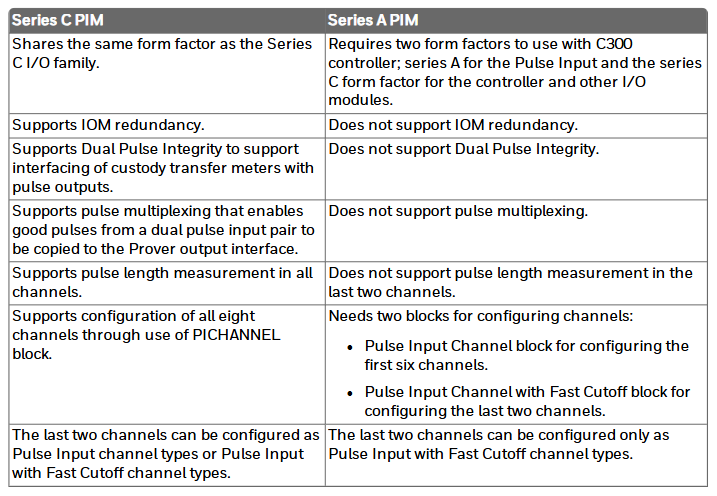

Series C I/O Definition: It is a series of traditional and special function input/output signal interface devices that support local software configuration, share the same external specifications with the C300 controller, and use the same installation system.

Series C I/O Mark II: It is an enhancement of the existing Series C platform in terms of IO modules, related IOTA, IO links, power supply, distribution, and cabinet infrastructure, making it more cost-effective. The design style remains unchanged, but it does not support any PM I/O.

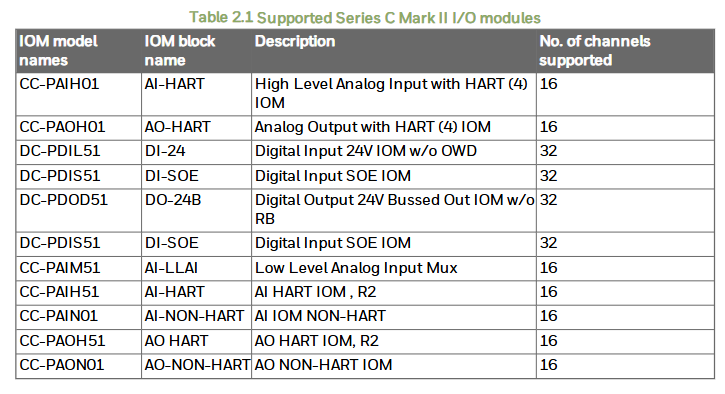

Series C Pulse Input Module (SCPIM): capable of high-precision pulse counting, with 8 input channels, some of which can be configured as dual inputs, and the last 2 channels can also be configured as fast cut-off outputs. It has multiple functions and is different from Series A PIM in terms of external specifications, redundancy support, and other aspects.

Honeywell Experion PKS Series C I/O

Series C I/O Usage

Comparison with Process Manager I/O: There are differences in non-volatile memory, IOL speed, HART support, master-slave module separation, installation environment, and configuration of memory backup.

Series C I/O Definition: It is a series of traditional and special function input/output signal interface devices that support local software configuration, share the same external specifications with the C300 controller, and use the same installation system.

Series C I/O Mark II: It is an enhancement of the existing Series C platform in terms of IO modules, related IOTA, IO links, power supply, distribution, and cabinet infrastructure, making it more cost-effective. The design style remains unchanged, but it does not support any PM I/O.

Series C Pulse Input Module (SCPIM): capable of high-precision pulse counting, with 8 input channels, some of which can be configured as dual inputs, and the last 2 channels can also be configured as fast cut-off outputs. It has multiple functions and is different from Series A PIM in terms of external specifications, redundancy support, and other aspects.

Universal Input/Output (UIO) module: 32 channels can be independently configured into multiple types, supporting multiple functions. There are differences in temperature range and channel configuration compared to existing Series C AI, AO, DI, DO modules.

Low level analog input (LLAI) module: used for low-voltage devices, supports 16 channels, accepts millivolt level temperature input, has many characteristics, and differs from AI-LLMUX modules in terms of channel quantity and other aspects.

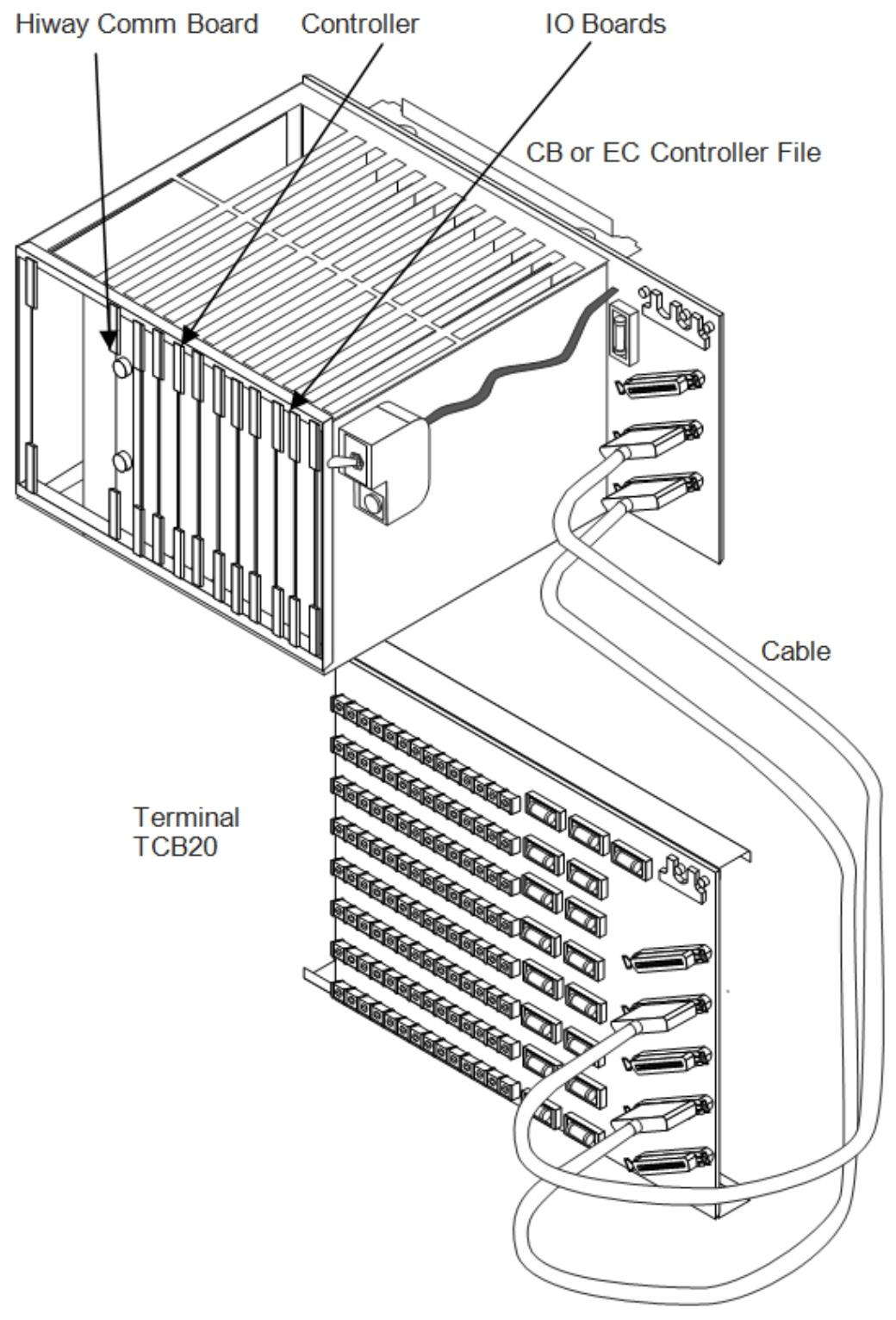

Overview of Universal Horizontal Input/Output (UHIO): It can replace the TDC 2000 basic controller and expansion controller, and introduces the mapping, functions, hardware, differences from Series C IOTA, and certification related content with CB/EC rack.

Series C I/O Planning and Design

General planning reference: Referring to relevant planning documents, introduce the appearance of Series C I/O and the functional characteristics of various modules.

Compared to the C300/CN100 topology structure, it follows certain topology rules, involving redundancy, switching, initialization, number of I/O links, performance, capacity, and other aspects.

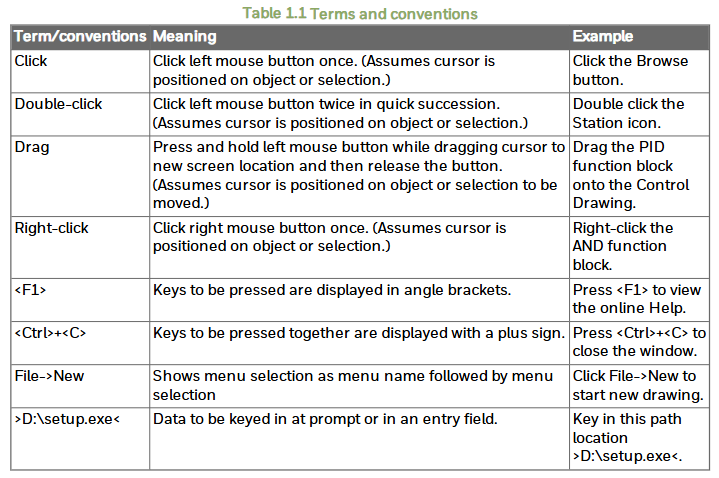

Supported Series C I/O modules: List various module models, names, descriptions, and compatibility matrices, differences between different module models, identification methods, redundant configuration considerations, and lifecycle changes.

Supported Series C I/O options: including multiple options, as well as checking I/O libraries, IOM function blocks, channel function blocks, defining module inclusion relationships, and calculating UIO temperature derating and internal dissipation.

I/O link performance specifications: Introduces the concept of link units, transmission rates, as well as link unit utilization, reducing I/O link traffic, event collection, PV, and reverse calculation scanning.

Universal Input/Output Module 2 (UIO-2): In addition to all the functions of UIO, it also has enhanced features, which differ from UIO-1 in multiple aspects.

Series C I/O installation and upgrade

Installation statement: Emphasize that equipment installation must comply with relevant electrical specifications, pay attention to electrostatic discharge protection, and ensure safe operation in hazardous areas.

Installing Series C IOTA onto the carrier: Certain prerequisites must be met and specific steps must be followed for installation.

Installing the I/O module to IOTA: There are corresponding prerequisites and installation steps, and attention should be paid to the use of screws during installation.

Grounding and power considerations for IOTA board: Introduces the connection and power testing methods and precautions for IOTA board.

Connecting IOM and field devices through I/O terminal components: illustrates the relationship between IOM types and auxiliary hardware, and related tables.

Power supply for Series C system: The power system provides multiple functions, similar to the Process Manager power system.

Series C IOTA board fuse: All IOTAs must contain at least one fuse, and the relevant properties are described.

Series C IOTA Pin Allocation

Detailed introduction of various IOTA models, including analog input, output, digital input, output, low-level analog input multiplexer, speed protection module, servo valve locator module, universal input/output, etc., involving terminal block wiring, field wiring, module protection, allowed wiring resistance, board connection, and other contents.

Series C PIM Connection

Connection diagram: shows the various components and signal processing flow of PIM connection.

On site device output stage types: Introduces various output stage types and their compatibility with PIM.

PIM resistor bias terminal block: used for installing appropriate bias resistors, introduces related operations.

Definition and allocation of pins for each terminal block: including signal definition and pin allocation for TB1, TB2, TB3, and TB4.

Pulse verification enabled: Select the flow to be verified in Control Builder.

Connection with other devices: Introduces the connection methods with ST500 dual pulse simulator, dual current devices, other sensor types, as well as input threshold selection and recommended cable types.

Series C Universal Horizontal Input/Output (UHIO) Components

Introduced the system and grounding audit checklist for horizontal C300/CF9 IOTA, horizontal UHIO IOTA, I/O connectors, TDC 2000 system, UHIO components, installation, general regulatory compliance, COTS AC-DC power supply, protective grounding, and environmental characteristics.

Universal Input/Output (UIO) module for rail installation

Advantages: Low space consumption, high cost-effectiveness, and simple component relocation.

Physical description: Introduces the composition of the components and the model, size, weight, and other information of some components.

Input/Output Link (IOL) Management: Supports specific UIO IOTA versions and DIN rail installations, and introduces relevant cables.

Single mode FOE: It is a necessary component for installing UIO on rails, and its component options, installation positions, etc. are introduced.

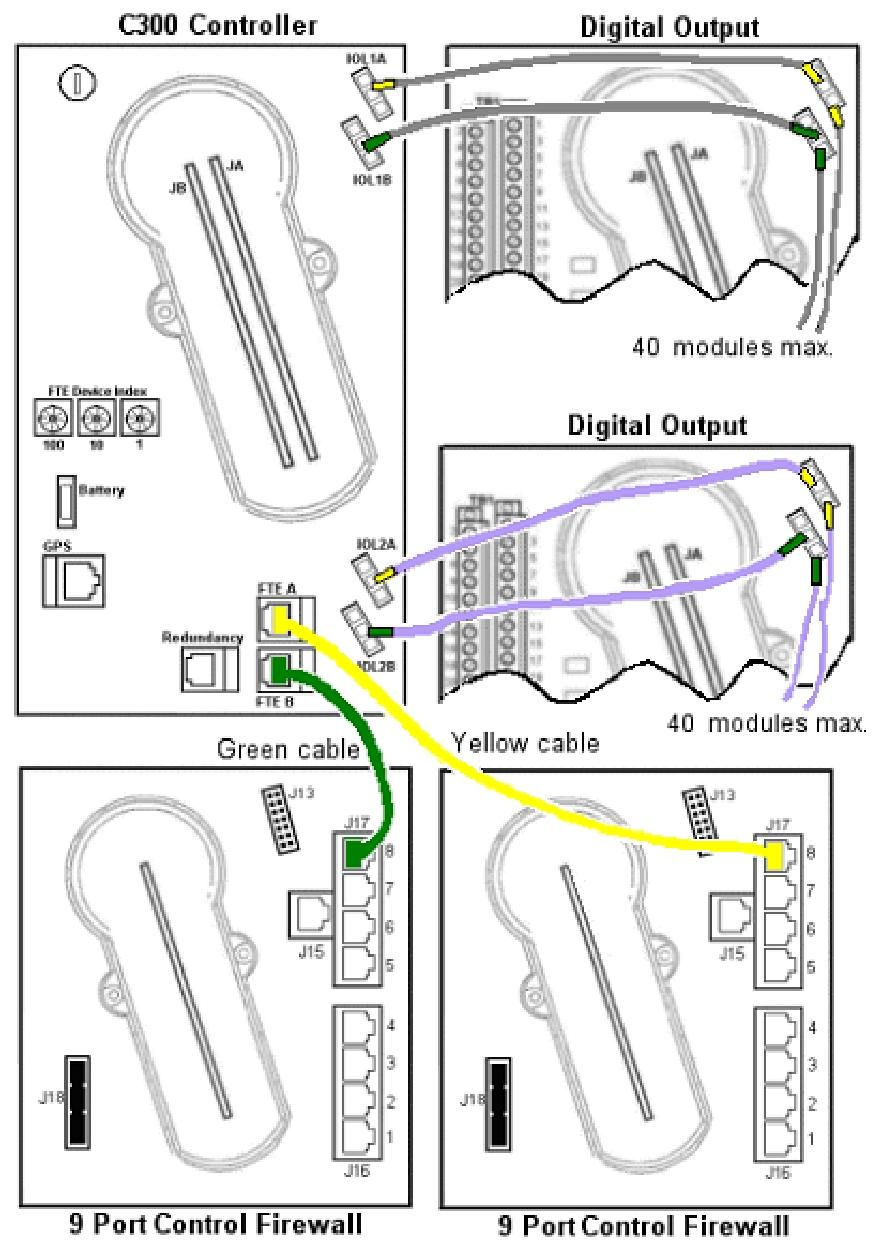

System wiring: It demonstrates the end-to-end connection of UIO modules installed on rails in a single cabinet and adjacent cabinets.

Power requirements: Powered by a+24VDC remote industrial grade power supply, including voltage range, power consumption, related protection, wiring, fuse terminal blocks, and circuit breakers.

Institutional certification: Possessing certifications such as CE, CTick, HAZLOC, etc.

Environmental conditions: Clearly defined environmental parameters such as temperature and humidity for work and storage.

Module assembly, installation, connection, disassembly: Detailed introduction of relevant steps and precautions.

Replaceable spare parts: lists the models and names of some replaceable spare parts.

Reference for Series C I/O Configuration Form

Determine redundancy: IOM blocks represent hardware instances of I/O modules, configurable redundancy, and generate system events and alerts.

Switching and secondary readiness: Switching is the process of a secondary module becoming a primary state, and the readiness state of the secondary module determines whether it can take over control functions.

Fault conditions and switching: Some faults may cause switching, such as primary module power failure, while others may not.

Configuration tool: Creating control policies using the Expert Control Builder requires multiple operations, and the IOM must be present during configuration loading.

Each tag configuration: detailed introduction Main、Server History、Server Displays、Control Confirmation、Identification、QVCS、Calibration、HART Status The parameter configuration method and content of the waiting tab.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923