K-WANG

Foxboro Evo FBM217 Discrete Input Module

Foxboro Evo FBM217 Discrete Input Module

Core functions and features of the module

FBM217 is a 32 channel discrete input module designed specifically for industrial environments, supporting multi voltage level signal acquisition and high reliability operation. Its core functions and features are as follows:

(1) Core functions

Multi voltage signal support: covering low, medium, and high voltage inputs, including:

Low voltage: 15~60V DC (voltage monitoring or contact detection);

Medium voltage: 120V AC/125V DC (logic 0:0~20V AC/DC, logic 1:80~132V AC/75~150V DC);

High voltage: 240V AC (logic 0:0~40V AC, logic 1:164~264V AC).

Redundancy deployment capability: Supports single module or redundant paired deployment (2 FBM217s need to be installed in adjacent odd/even positions on the base, with the redundant adapter RH926ZY). In redundancy mode, the input signal quality is verified through the CINR function block of Foxboro Evo control software, and the optimal signal is automatically selected.

Event Sequence (SOE) Function: In conjunction with I/A Series v8. x and above software or Control Core Services v9.0+, supports event collection, storage, and reporting, with optional GPS time synchronization (accuracy up to 1ms); The old version software (before v8. x) needs to be implemented through the ECB6/EVENT block, with an accuracy of 1 second and no cross processor synchronization.

Signal conditioning and protection: relying on termination components (TAs) to achieve optical isolation, current limitation, and voltage attenuation. Some TAs support external excitation power supply access without the need for additional on-site circuit protection equipment (such as fuses).

(2) Key characteristics

Environmental adaptability: Complies with ISA S71.04 G3 level harsh environmental standards, can withstand vibration (0.75 m/S ² @ 5-500Hz), wide temperature range (working -20~70 ℃, storage -40~70 ℃);

Hot swappable design: When replacing modules, there is no need to remove on-site wiring, power or communication cables. The replacement of redundant modules does not affect the on-site signal acquisition of normal modules;

Status indication: The front LED light provides real-time feedback on the operating status of the module (such as fault, ready) and the discrete status of a single input channel, facilitating quick diagnosis;

Communication reliability: Connected to the Fieldbus Communication Module (FCM) or Control Processor (FCP) via a 2 Mbps module fieldbus, supporting A/B dual path communication and automatic switching in case of single path failure.

Hardware parameters and technical specifications

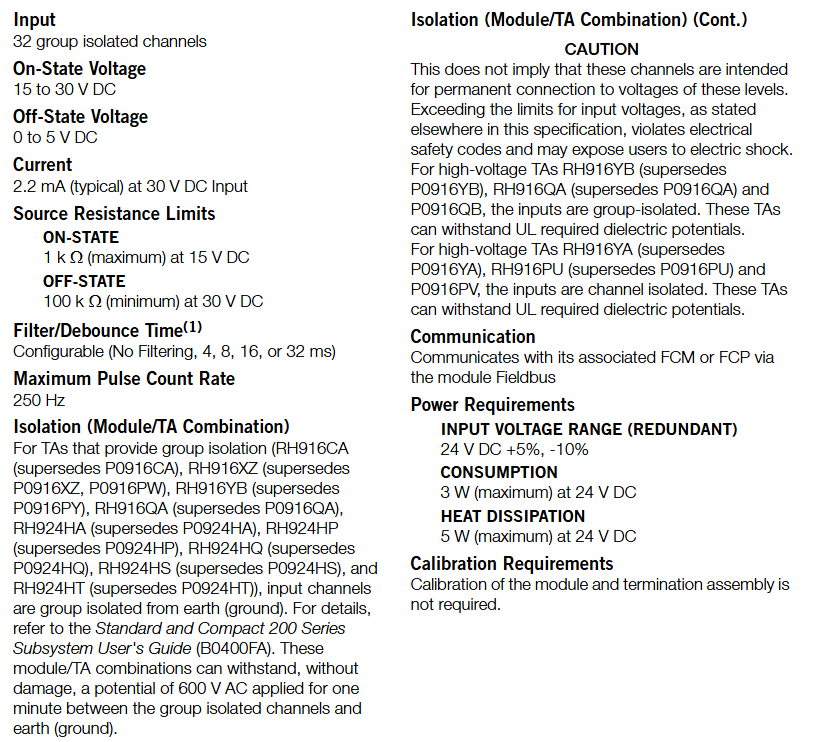

(1) Input and electrical parameters

Parameter category specific specifications

Channel configuration with 32 isolated channels (isolation level dependent on TA, some TAs support channel level isolation)

Typical 2.2mA at 30V DC input current; maximum 2.8mA at high voltage (240V AC) (logic 1 state)

Source resistance limit logic 1 (15V DC) ≤ 1k Ω; logic 0 (30V DC) ≥ 100k Ω

The filtering/debounce time can be configured (no filtering, 4ms, 8ms, 16ms, 32ms, firmware v1.25H+required)

Maximum pulse counting rate 250Hz

The combination of isolation voltage module and TA can withstand 600V AC (1 minute, group isolation channel to ground)

(2) Power supply and power consumption

Power input: 24V DC (redundant mode, allowable range+5%/-10%, i.e. 21.6-26.4V DC);

Power consumption: maximum 3W at 24V DC (operation), maximum heat dissipation 5W;

Power protection: Supports redundant independent DC power supply access to enhance power supply reliability.

(3) Physical and environmental parameters

Parameter category specification requirements

Dimensions (module) Height 102mm (including installation ears 114mm) x Width 45mm x Depth 104mm

The weight module weighs approximately 284g (10oz); TA approximately 420-454g (0.93-1.0lb)

Working environment temperature -20~70 ℃, humidity 5%~95% (non condensing), altitude -300~3000m

Storage environment temperature -40~70 ℃, humidity 5%~95% (no condensation), altitude -300~12000m

The pollution level complies with EIA 364-65 Class III and is suitable for harsh environments of ISA S71.04 G3 level

Installation and Termination Component (TA) Configuration

FBM217 needs to be used in conjunction with a dedicated base and termination assembly (TA), and installation and wiring must follow strict specifications. The core requirements are as follows:

(1) Base and installation

Base type: Modular base (DIN rail or 19 inch rack mounted), with a maximum capacity of 4 or 8 FBM modules per base;

Redundant modules need to be installed in adjacent odd/even positions (such as 1&2, 3&4) and connected through redundant adapter RH926ZY;

Support 100 series conversion installation structure (refer to PSS 31H-2W8) for easy upgrading of old systems.

Installation specifications:

DIN rail: Supports 32mm/35mm specifications, with priority given to galvanized yellow chromium steel material (ensuring good grounding), fixed at a spacing of approximately 200mm;

Panel installation: Use M4 or # 8 screws and reserve heat dissipation space (≥ 25mm on each side of the module).

(2) Termination Component (TA) Selection

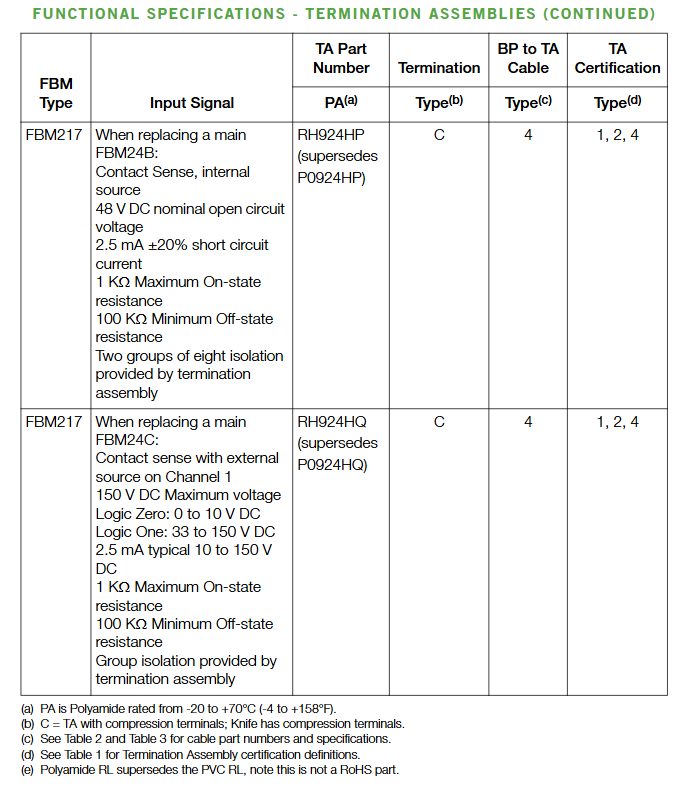

TA is the core component connecting FBM217 with on-site signals, providing signal conditioning, isolation, and power distribution functions. It needs to be selected according to the input signal type. Common TA and adaptation scenarios are as follows:

TA model adaptation signal type isolation level certification type

RH916CA (main TA) 30V DC voltage monitoring, 32 channel group isolation Type 1/2/4

RH916XZ (main TA) 24V DC contact detection, 32 channel group isolation Type 1/2/4

RH916YA (main TA) 132V AC/150V DC voltage monitoring, 32 channel isolation Type 1/4

RH916PU (main TA) 240V AC voltage monitoring, 32 channel isolation Type 1

RH924HB (Extended TA) replaces FBM12A/B expansion module, 16 channel group isolation Type 1/2/4

RH924HD (Extended TA) replaces FBM13 expansion module, 16 channel isolation Type 1/4

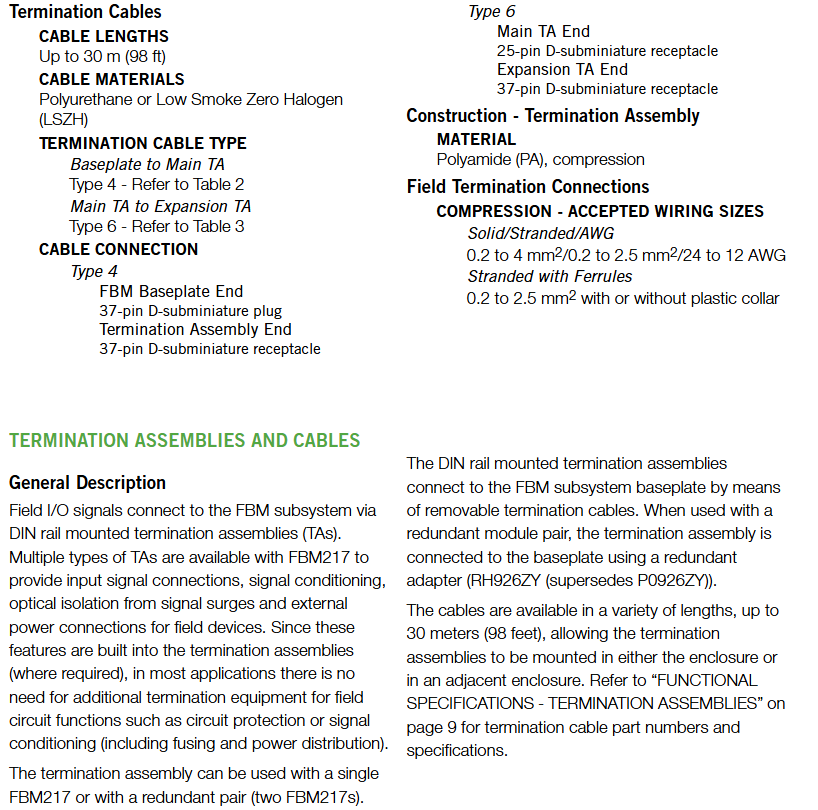

TA connection: The main TA is connected to the base through a Type 4 cable (37 pin D-sub interface), and the extended TA is cascaded through a Type 6 cable (main TA 25 pin → extended TA 37 pin), with a maximum cable length of 30m, supporting P/PVC or LSZH materials (LSZH is suitable for low smoke and halogen-free scenarios);

Upgrade adaptation: When replacing the 100 series FBM (such as FBM07A/B, FBM08, FBM20), it is necessary to match the corresponding main TA+extended TA (such as replacing FBM07A with RH924HA main TA+RH924HB extended TA).

Compliance certification and security requirements

(1) Core certification

The FBM217 module and its supporting TA comply with global safety and electromagnetic compatibility standards in multiple regions, with the following core certifications:

Specific standards and levels for certification categories

Hazardous Area Certification North America: UL/UL-C Class I Division 2 Groups A-D, Temperature Code T4;

Europe: ATEX 2014/34/EU II 3 G Ex nA IIC T4 (DEMKO certification);

International: IECEx Ex nA IIC T4, certificate number refers to relevant TA documents

Electromagnetic compatibility (EMC) complies with EN 61326-1:2013 Class A (Emission and Immunity in Industrial Environments), EU EMC Directive 2014/30/EU

Low voltage safety EU Low Voltage Directive 2014/35/EU, in compliance with EN 61131-2 standard; UL Class 2 Circuit (Communication Circuit)

Environmental compliance complies with the EU RoHS 2011/65/EU directive, restricting the use of hazardous substances

Ship certification ABS type approval, French Classification Society (BV) EC31 environmental category certification

(2) Safety operation requirements

Electrical safety:

On site wiring must comply with Class 2 circuit restrictions (60V DC/30V AC, below 100VA), and high voltage TA must avoid long-term overvoltage operation (such as prohibiting the connection of signals above 300V AC to 240V AC modules);

Grounding requirements: The base is grounded through a DIN rail, and the use of aluminum/plastic rails is prohibited (which may cause poor grounding). The TA isolation channel needs to be grounded separately.

Dangerous area operation:

It needs to be installed in a certified enclosure with a protection level of IP54 or higher, and the enclosure needs to be opened with tools;

Before connecting/disconnecting cables, power off or confirm that the area is in a non hazardous environment. Replacement of non certified components is prohibited.

Upgrade and compatibility instructions

FBM217 is mainly used to replace Foxboro 100 series discrete input FBM modules. When upgrading, the following compatibility points should be noted:

Hardware replacement: A single FBM217 can replace one 100 series main FBM (such as FBM07A/B, FBM08)+one extended FBM (such as FBM12, FBM13), which needs to be matched with the corresponding functional main TA and extended TA (refer to the document "TA Selection Table for Migration");

Software adaptation:

New system: requires Studio 5000 or Foxboro Evo control software v8. x+, supporting redundant CINR blocks and GPS SOE synchronization;

Old system: 100 series upgrade can use termination component adapter (TAA, refer to PSS 31H-2W4) without rewiring;

Cable Reuse: Some 100 series on-site cables can be adapted to FBM217 through TAA, but the voltage level and TA compatibility need to be confirmed.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923