K-WANG

Foxboro Evo ™ FBM217 Discrete Input Module

Foxboro Evo ™ FBM217 Discrete Input Module

Product positioning: FBM217 is a highly compatible and reliable 32 channel discrete input module, suitable for the acquisition of various switch signals (such as sensors, contactor contacts) in industrial sites. It supports single module independent operation or dual module redundant configuration, and is widely used in industries such as petrochemicals, power, and manufacturing that require high signal stability.

Product Core Features

The FBM217 module meets the high requirements of industrial scenarios through hardware design and functional optimization, with the following core features:

Multi channel and wide voltage support:

Provides 32 discrete input channels, with a single channel that can flexibly adapt to multiple signal types: 15-60V DC (low voltage), 120V AC/125V DC (medium voltage), 240V AC (high voltage), compatible with voltage monitoring (requires external power supply) and contact detection (can use module auxiliary power supply) modes.

Support cascading of "main extension" terminal components (TA), which can increase signal access capability by extending TA and adapt to upgrade and replacement scenarios of 100 series FBM modules (such as FBM07A/B, FBM20).

Redundancy and reliability design:

Support single module or dual module redundant configuration: In redundant mode, two FBM217s share a terminal component through a redundant adapter (P0926ZY), doubling the field input current. When the module fails, it automatically switches to the backup module, ensuring uninterrupted signal acquisition.

The redundant logic is implemented by the CINR function block of Foxboro Evo control software, which synchronously reads data from two modules during each execution cycle, selects high-quality signals to participate in control, and enhances the system's fault tolerance.

Signal processing and protection:

Programmable filtering/debounce time: supports 5 configurations of "no filtering, 4ms, 8ms, 16ms, 32ms", which can be adjusted according to the on-site interference situation to reduce signal false triggering caused by high-frequency noise.

Terminal assembly (TA) integrated protection function: including high-voltage attenuation circuit, optocoupler isolation, current limiting device, some TAs support channel level or group level isolation (such as P0916PS/PT supporting channel isolation), withstand 600V AC (1 minute) to ground voltage, and avoid signal surge damage to the module.

Convenient maintenance and visualization:

Integrated LED indicator lights on the front panel: display module operating status (such as bus communication, power supply) and discrete status of 32 channels (on/off), intuitively locating faulty channels.

Hot swappable design: Modules can be replaced without disconnecting field wiring, power or communication cables. Under redundant configuration, replacing a single module does not affect field signal input and reduces system downtime.

Functional specification parameters

(1) Input signal and electrical parameters

Parameter category specific specifications

32 channels, group isolation (some TAs support channel isolation)

On State voltage 15-30V DC (low voltage); 80-132V AC/75-150V DC (medium voltage); 164-264V AC (high voltage)

Off State voltage 0-5V DC (low voltage); 0-20V AC/0-20V DC (medium voltage); 0-40V AC (high voltage)

Typical input current 2.2mA (at 30V DC); 1.6mA (maximum value at high voltage)

When the source resistance limits conduction, it is ≤ 1k Ω (15V DC); When turned off, ≥ 100k Ω (30V DC)

Pulse counting capability up to 250Hz, supporting pulse signal acquisition (such as flow meter pulses)

(2) Communication and Power Supply

Communication interface: Connected to the fieldbus communication module (FCM) or control processor (FCP) through a 2Mbps module fieldbus, supporting A/B dual path redundancy, automatically switching to the backup path in case of single path failure, ensuring data transmission continuity.

Power requirements:

Input voltage: 24V DC (in redundant configuration), allowing ± 5% (upper limit) and -10% (lower limit) fluctuations.

Power consumption: maximum 3W (at 24V DC); Thermal Dissection: Maximum 5W (at 24V DC), no additional calibration required.

(3) Isolation and protective performance

Isolation level: The module and terminal assembly (TA) combination has high isolation capability, and the group isolation TA (such as P0916CA, P0924HA) can withstand 600V AC (1 minute) to ground voltage; High voltage TA (such as P0916PY, P0916QB) meets UL dielectric potential requirements, and channel isolation TA (such as P0916PS, P0916PU) further enhances anti-interference ability.

Electromagnetic compatibility (EMC): Complies with the European EMC Directive 2004/108/EC and multiple international standards, as follows:

Radiation emission: EN 50081-2 (industrial environment) CISPR 11 Class A;

Immunity: ESD (contact 4kV/air 8kV), radiation field (10V/m, 80-1000MHz), electrical fast transient (2kV, I/O/power/communication line), surge (2kV AC/DC power line, 1kV I/O/communication line), etc.

Environmental and Physical Specifications

(1) Environmental adaptability

The FBM217 module and terminal assembly (TA) meet the requirements of harsh industrial environments, with specific parameters as follows:

Environmental Category Module (FBM217) Terminal Assembly (TA) - PVC Material Terminal Assembly (TA) - PA Material

Working temperature -20~+70 ℃ (-4~+158 ° F) -20~+50 ℃ (-4~+122 ° F) -20~+70 ℃ (-4~+158 ° F)

Storage temperature -40~+70 ℃ (-40~+158 ° F) -40~+70 ℃ (-40~+158 ° F) -40~+70 ℃ (-40~+158 ° F)

Relative humidity 5%~95% (no condensation) 5%~95% (no condensation) 5%~95% (no condensation)

Altitude work: -300~+3000m (-1000~+10000ft); Storage: -300~+12000m (-1000~+40000ft) same module same module

The pollution level complies with ISA S71.04 G3 level (harsh environment) and has passed EIA 364-65 Class III exposure testing for the same module

Vibration tolerance 0.75m/s ² (5-500Hz) same module same module

(2) Physical and installation parameters

Module size and weight:

Dimensions: Height 102mm (4in, excluding mounting ears)/114mm (4.5in, including mounting ears), Width 45mm (1.75in), Depth 104mm (4.11in);

Weight: Approximately 284g (10oz), lightweight design facilitates dense installation.

Installation method:

Module: Installed on a DIN rail base plate (supporting 4 or 8 slots), the base plate can be installed horizontally/vertically on a DIN rail, or adapted to a 19 inch rack through an installation kit; Redundant modules need to be installed in odd even positions adjacent to the base plate (such as slots 1-2 and 3-4).

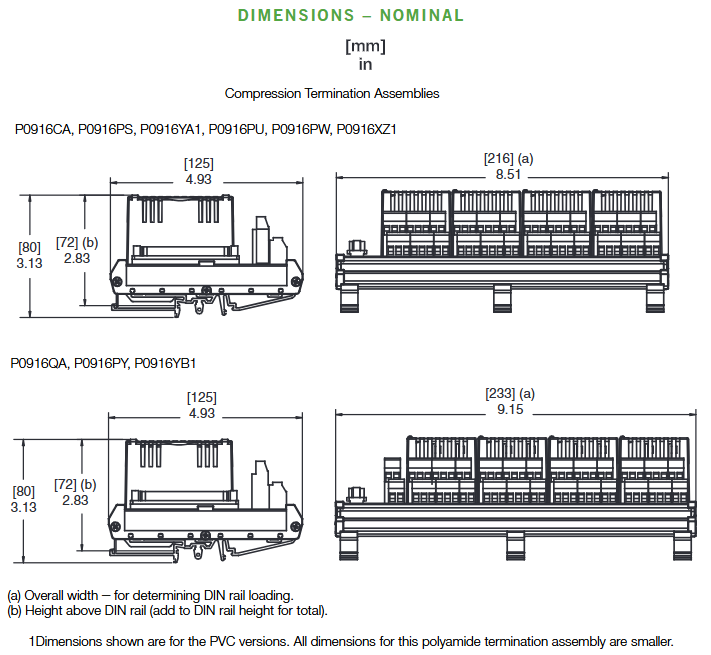

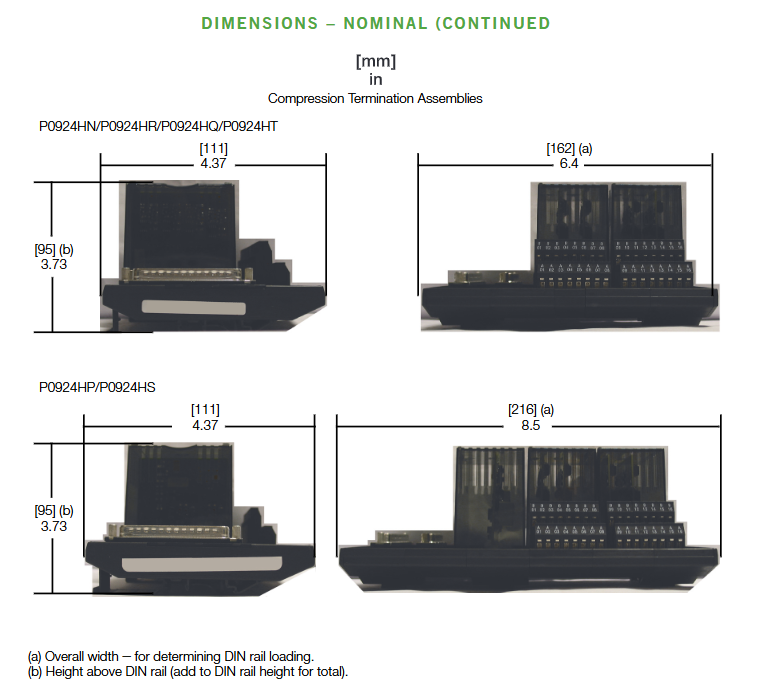

Terminal Assembly (TA): DIN rail mounting, compatible with 32mm (1.26in) and 35mm (1.38in) standard rails, supports compression terminals (24-12 AWG wires) or ring terminal blocks (22-12 AWG wires).

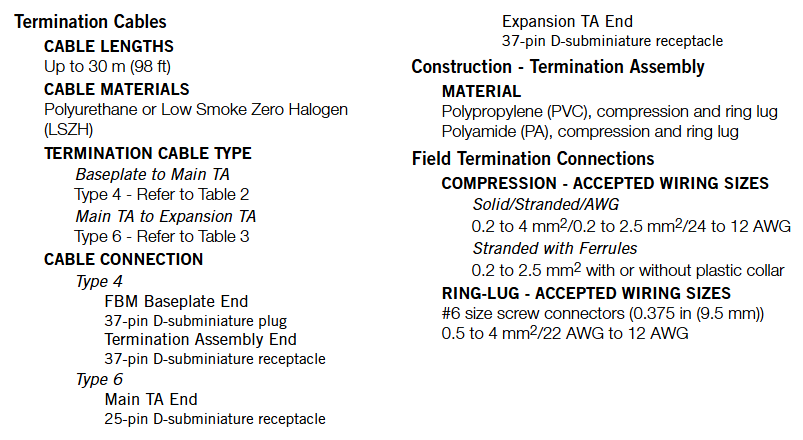

Cable specifications:

Base board to main TA: Use Type 4 cable (37 pin D-sub interface), with a maximum length of 30m (98ft), optional polyurethane (P/PVC), low smoke halogen-free (LSZH) materials, suitable for temperature resistance and environmental protection requirements in different environments;

Main TA to Extended TA: Use Type 6 cable (25 pins on the main TA end and 37 pins on the extended TA end), with a length of 0.75m (2.5ft), only available in LSZH material.

Terminal Assembly (TA) and Compatibility

Terminal assembly (TA) is a key interface between FBM217 and on-site equipment, providing signal conditioning, isolation, and power distribution functions. Different TAs are adapted to different signal scenarios, and the core parameters are as follows:

(1) Classification and adaptation of main terminal assembly (TA)

FBM type input signal type TA model (PVC/PA material) terminal type cable type certification level

FBM217 30V DC Voltage Monitoring (Group Isolation) P0916CA/P0916CB Compression/Ring Lug Type 4 1, 2, 4

FBM217 24V DC contact detection (group isolation) P0916PW/P0916PX (PVC); P0916XZ (PA) Compression/Ring Lug Type 4 1, 2, 4

FBM217 120V AC/125V DC voltage monitoring (channel isolation) P0916PS/P0916PT (PVC); P0916YA (PA) Compression Type 4 1, 4

FBM217 120V AC/125V DC contact detection (group isolation) P0916PY/P0916PZ (PVC); P0916YB (PA) Compression/Ring Lug Type 4 1, 4

FBM217 240V AC Voltage Monitoring (Channel Isolation) P0916PU/P0916PV Compression/Ring Lug Type 4 1

FBM217 240V AC Contact Detection (Group Isolation) P0916QA/P0916QB Compression/Ring Lug Type 4 1

FBM217 replaces FBM07A (15-130V DC voltage monitoring) P0924HA compression type 4 1, 2, 4

FBM217 replaces FBM08 (120V AC/125V DC voltage monitoring) P0924HC compression type 4 1, 4

(2) Expansion Terminal Assembly (TA) adaptation

Expanding TA is used to increase the number of channels and needs to be cascaded with the main TA to adapt to the upgrade of the 100 series extended FBM module. The core models are as follows:

Compatible with 100 series extended FBM input signal specifications, extended TA model (PA material), cable type certification level

FBM12A/B (16 contacts/voltage) with main TA P0924HA P0924HB Type 6 1, 2, 4

FBM13 (16 channel voltage monitoring) with main TA P0924HC P0924HD Type 6 1, 4

FBM21 (16 channel voltage monitoring) with main TA P0924HL P0924HM Type 6 1

FBM25B (16 way contact detection) with main TA P0924HP P0924HS Type 6 1, 2, 4

(3) Certification Level Definition (Table 1)

TA certification strictly follows international safety standards, and different levels correspond to different application scenarios:

Type 1: UL/UL-C certification, suitable for Class I A-D Group 2 hazardous environments (temperature code T4); CENELEC (DEMKO) certification for Zone 2 potentially explosive environments (EEx nA IIC T4).

Type 2: In addition to Type 1, it also meets the requirements of "non flammable on-site circuits" and is compatible with Class 2 limited energy circuits (60V DC/30V AC, ≤ 100VA).

Type 4: All on-site circuits meet Class 2 limited energy requirements and require external equipment to comply with Class 2 restrictions.

Compliance Certification and System Integration

(1) Regulatory Compliance Certification

The FBM217 module and TA have passed multiple international certifications to ensure compliant use in different regions and industries

Electromagnetic compatibility (EMC): Complies with the European EMC Directive 2004/108/EC, meets EN 50081-2 (emission), EN 50082-2 (immunity), EN 61326 (industrial grade) standards, is compatible with CISPR 11 Class A limits, and is resistant to interference such as ESD, radiated fields, and electrical fast transients.

Product safety:

UL/UL-C certification: applicable to Class I A-D Group 2 hazardous environments (T4 temperature code), as an "associated device" supplying power to non flammable circuits;

European Low Voltage Directive (2006/95/EC) and ATEX Directive (94/9/EC): CENELEC (DEMKO) certified, suitable for Zone 2 environments, supplying power to Group IIC non flammable field circuits.

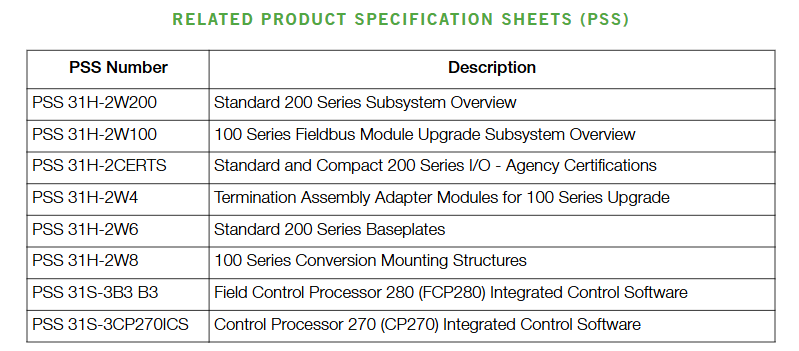

(2) System integration and upgrade

100 series FBM module upgrade: FBM217 can directly replace 100 series discrete input modules (such as FBM07A/B, FBM08, FBM20), and achieve hardware compatibility and functional upgrades by adapting the corresponding TA (such as P0924HA replacing FBM07A), without the need to reconstruct on-site wiring.

Event Sequence (SOE) Integration: Supports SOE functionality for Foxboro Evo v8. x and above software, combined with GPS time synchronization (optional), enabling millisecond level event collection, storage, and reporting across control processors; Versions below v8. x require SOE implementation through ECB6 and EVENT blocks, with a time accuracy of seconds and no cross processor synchronization.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

-

XYCOM CU040103500 - VME Rack System Module 4200401

-

XYCOM XVME-085 - Proto VMEbus Non-Intelligent Prototyping Module

-

XYCOM XVME-100 - PCB Controller Card ROM Board 70100-001

-

XYCOM XVME-103 - VMEbus Board 10103-001

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923