K-WANG

Allen-Bradley SLC 500 ™ 1746 series I/O modules

I/O module: Various functional modules of the 1746 series (such as digital IB/OB series, analog NI/NO series, special function modules) provide signal acquisition and control output functions for the system.

I/O rack (Chassis): includes models such as 1746-A1 (1 slot), 1746-A2 (2 slots), 1746-A7 (7 slots), 1746-A10 (10 slots), etc., used for installing modules and providing backplane buses (data and power transmission). Slot 0 is default for processor modules (such as 1747-L511), and the rest are I/O module slots.

Power modules, such as 1746-P2 (24V DC 2.0A) and 1746-P4 (24V DC 4.0A), provide stable DC power to the rack and modules. The appropriate model should be selected based on the total power consumption of the module.

Communication link: Supports industrial buses such as DH-485, ControlNet, DeviceNet, etc., to achieve data exchange between I/O modules, processors, and upper computers.

Allen-Bradley SLC 500 ™ 1746 series I/O modules

Overall architecture of 1746 I/O system

(1) System composition

The 1746 I/O system is a modular expansion unit of the SLC 500 programmable logic controller, with core components including:

I/O module: Various functional modules of the 1746 series (such as digital IB/OB series, analog NI/NO series, special function modules) provide signal acquisition and control output functions for the system.

I/O rack (Chassis): includes models such as 1746-A1 (1 slot), 1746-A2 (2 slots), 1746-A7 (7 slots), 1746-A10 (10 slots), etc., used for installing modules and providing backplane buses (data and power transmission). Slot 0 is default for processor modules (such as 1747-L511), and the rest are I/O module slots.

Power modules, such as 1746-P2 (24V DC 2.0A) and 1746-P4 (24V DC 4.0A), provide stable DC power to the rack and modules. The appropriate model should be selected based on the total power consumption of the module.

Communication link: Supports industrial buses such as DH-485, ControlNet, DeviceNet, etc., to achieve data exchange between I/O modules, processors, and upper computers.

(2) System characteristics

Modular design: Modules can be combined as needed, supporting mixed installation of digital, analog, and special functional modules, and flexibly adapting to different industrial scenarios (such as manufacturing production lines and process control).

Backplane bus technology: The rack is equipped with a 16 bit data bus with a transmission rate of 1Mbps, ensuring real-time data exchange between modules. Class 1/3 interface modules can flexibly allocate memory addresses.

Environmental adaptability: The entire series of modules comply with industrial standards, with a working temperature range of 0-60 ℃ (some modules can withstand high temperatures of 60 ℃ in the rightmost slot), humidity of 5% -95% (no condensation), and adaptability to complex environments such as workshops and outdoor control cabinets.

Redundancy and Expansion: Supports multi rack expansion (connected through communication modules), and some key modules (such as power and control modules) can be configured redundantly to improve system reliability.

Module Classification and Core Features

The 1746 series I/O modules are divided into four categories according to their functions, and the core models and characteristics of each category are as follows:

(1) Digital input module

Model Channel Number Input Type Core Characteristics Typical Applications

1746-IB16 16 16 channel 24V DC sinking 4 groups isolated (4 points/group), response time ≤ 3ms, with fuse protection (Series A/B/C) button, limit switch signal acquisition

1746-IB32 32 channel 24V DC sinking 4 groups isolated (8 points/group), low-power design, suitable for high-density signal acquisition pipeline workstation status monitoring

1746-IV16 16 16 channel 24V DC sourcing has the same structure as IB16, with opposite input polarity, and is compatible with PNP type sensor photoelectric sensor signal acquisition

1746-IV32 32 channel 24V DC sourcing 32 channel high-density design, inter group isolation, supports long-term operation in harsh environments, multi state monitoring of large equipment

(2) Digital output module

Model Channel Number Output Type Core Characteristics Typical Applications

1746-OB16 16 24V DC sourcing 2 groups isolated (8 points/group), single channel maximum current 0.5A, with fuse protection small relay and indicator light control

1746-OB32 32 channel 24V DC sourcing 32 channel high-density, 2 groups isolated (16 points/group), total continuous current 8A multi actuator synchronous control

1746-OB32E 32 channel 24V DC sourcing with built-in electronic protection (short circuit, overload thermal cut-off), automatic reset of fault channels, key equipment control (requiring fault self recovery)

1746-OV16 16 channel 24V DC sinking output polarity opposite to OB16, compatible with NPN type actuators, inter group isolation solenoid valves, and small motor control

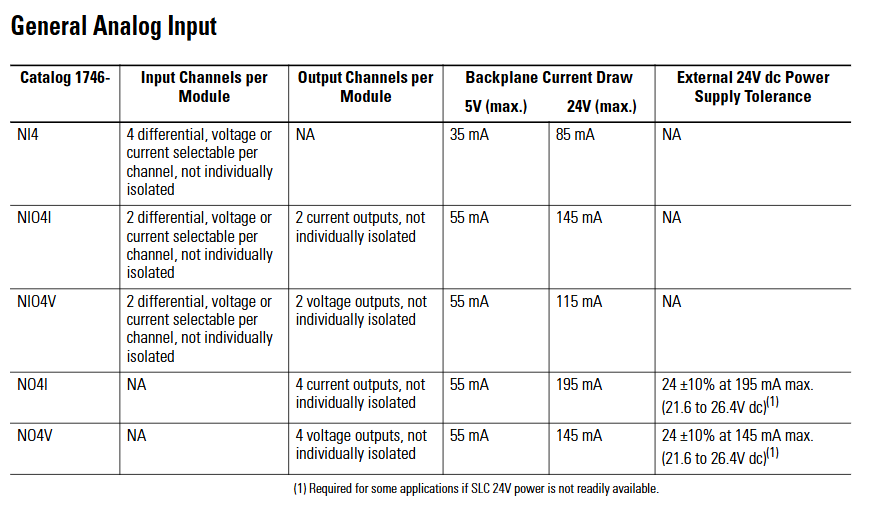

(3) Analog input module

Model Channel Number Input Signal Core Characteristics Typical Applications

1746-NI4 4-channel voltage (± 10V/0-10V, etc.), current (4-20mA, etc.) successive approximation A/D conversion, accuracy ± 0.1%, automatic temperature compensation pressure, temperature transmitter signal acquisition

1746-NI8 8-channel voltage and current, 8-channel high-density, supports single ended/differential wiring, programmable filtering (8 frequencies), multi parameter process monitoring (such as liquid level, flow rate)

1746-NR4 4-channel RTD (Pt100, Cu100, etc.) dedicated RTD signal conditioning, strong anti-interference ability, accurate ± 0.05% temperature monitoring (such as chemical reaction kettle)

1746-NT4 4-channel thermocouple (J, K, T, etc.) with built-in cold end compensation, supports open circuit detection, and is suitable for temperature acquisition in high-temperature environments such as kilns and heating furnaces

(4) Analog output module

Model Channel Number Output Signal Core Characteristics Typical Applications

1746-NO4I 4-channel current (4-20mA) D/A conversion accuracy ± 0.1%, output short-circuit protection, inter group isolation valve positioner, frequency converter control

1746-NO4V 4-channel voltage (0-10V/± 10V) with the same structure as NO4I, output type is voltage, suitable for voltage control equipment, analog speed control motor, indicator light brightness adjustment

1746-NO8V 8-channel voltage (0-10V) 8-channel high-density, total output load current ≤ 100mA, supports synchronous control of multiple devices and multi-channel analog signal output (as displayed on the dashboard)

System installation and configuration

(1) Rack and power installation

Rack selection: Choose slot positions based on the number of modules. 1746-A7 (7 slots) is suitable for small and medium-sized systems, while 1746-A10 (10 slots) is suitable for large systems; If expansion is required, multiple rack connections can be achieved through the 1747-SN module.

Power calculation: It is necessary to calculate the 5V DC and 24V DC power consumption of all modules to ensure sufficient output capacity of the power module (e.g. 1746-P2 provides 24V DC 2.0A, 1746-P4 provides 4.0A). The calculation formula is: total power consumption=∑ (5V current of each module)+∑ (24V current of each module).

Installation specifications:

The rack should be installed vertically to avoid tilting (tilt angle ≤ 5 °) and ensure good heat dissipation;

The power module should be located near the input end of the rack to reduce wire voltage drop;

The grounding resistance is ≤ 4 Ω, and the rack shell needs to be separately grounded to avoid electromagnetic interference.

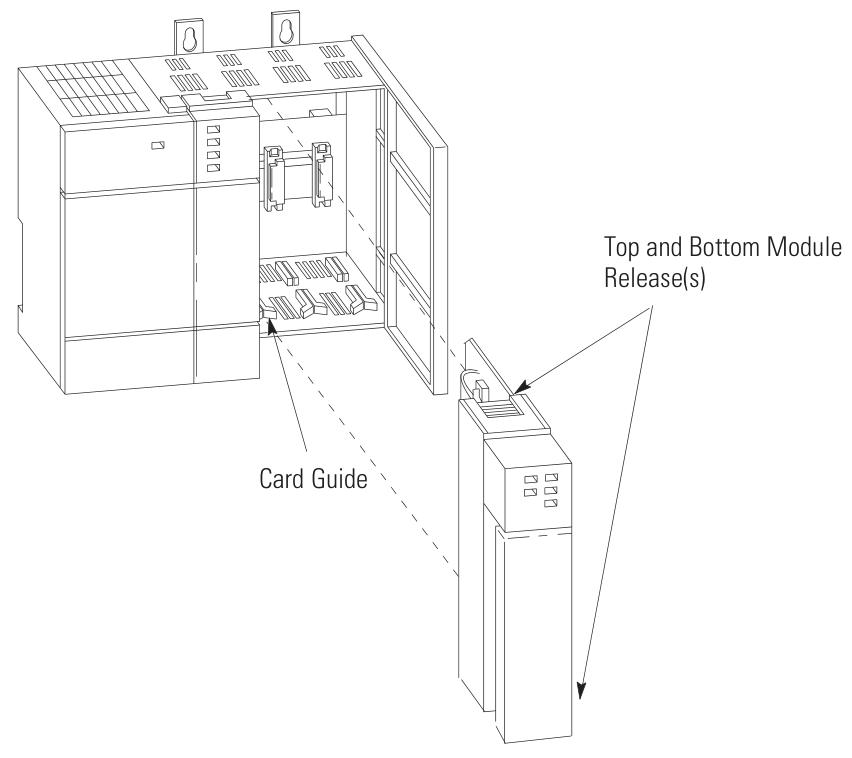

(2) Module installation steps

Static protection: Wear a grounding wristband before operation, store the module in an anti-static bag, and avoid touching the back panel pins.

Power off operation: Disconnect the power supply of the power rack before installation to prevent damage to the module or backplane caused by live plugging and unplugging.

Module insertion: Align the rack slot and slowly insert the module into the upper and lower self-locking tabs to secure it, without the need for additional screws; Idle slots require installation of 1746-N2 filling plates to prevent dust from entering.

Slot selection:

The processor module (such as 1747-L511) must be installed in slot 0;

Under high temperature conditions, install the heating module (such as a 32 point I/O module) in the rightmost slot (with a temperature tolerance of 60 ℃);

The analog module needs to be kept away from strong interference sources such as frequency converters and high-power motors to reduce signal fluctuations.

(3) Module address configuration

Address allocation principle:

Digital quantity module: Each 16 channel module occupies 1 input word/output word, and the 32 channel module occupies 2 input words/output words;

Analog module: Class 1 interface module (such as 1746-NI8) occupies 8 input words and 8 output words, while Class 3 interface module adds an additional status word address;

Address range: Input image area I: 0/0-I: 255/15, output image area O: 0/0-O: 255/15, avoid address overlap.

Configuration tool: Set the module ID code (such as 1746-NI8 Class 1 ID 3526) through RSLogix 500 programming software, and assign the corresponding input/output image area address. After configuration is complete, download it to the processor.

Wiring specifications and examples

(1) General Wiring Guidelines

Wire selection:

Digital module: Recommended 22-16 AWG shielded twisted pair (such as Belden 8761) to reduce electromagnetic interference;

Analog module: requires the use of twisted pair shielded wires (such as Belden 9239), with the shielding layer grounded at one end (near the signal source end) to avoid common mode interference;

Power cord: A 24V DC power supply requires the use of 18-14 AWG wires to ensure a voltage drop of ≤ 0.5V (the wire diameter needs to be increased for long-distance wiring).

Isolation and grounding:

The group isolation module needs to ensure that the common terminals (COM) of different groups are not connected together to avoid cross group short circuits;

The grounding of the analog module needs to be independent and separate from the power grounding, with a grounding resistance of ≤ 1 Ω;

The rack shell needs to be connected to the system grounding grid through grounding terminals to prevent static electricity accumulation.

Polarity and short circuit protection:

The DC module needs to strictly distinguish between positive and negative poles, and reverse connection may burn out the module (some modules have reverse connection protection);

The load end of the output module needs to be connected in series with a suitable fuse (such as 0.5A/250V) to prevent short circuit damage to the module caused by the load.

(2) Typical module wiring example

1746-IB32 (32 channel digital input):

4 sets of common terminals (COM1-COM4) correspond to channels 0-7, 8-15, 16-23, 24-31 respectively;

COM1-COM4 is connected to the negative pole of 24V DC, channels 0-31 are connected to the sensor output terminal, and+V1-V4 is connected to the positive pole of 24V DC;

When the current of a single group exceeds 2A, both common terminals of the group need to be connected simultaneously to avoid terminal overload.

1746-OB32E (32 channel digital output):

Two sets of common terminals (+V1,+V2) correspond to channels 0-15, 16-31;

+V1 and+V2 are connected to the positive pole of 24V DC, channels 0-31 are connected to the positive pole of the load, and the negative pole of the load is connected to the negative pole of 24V DC;

When a short circuit occurs, the E-Fuse LED lights up and automatically resets after the fault is removed, without the need to replace the fuse.

1746-NI8 (8-channel analog input):

Support single ended or differential wiring, single ended signals require the negative terminal of the signal to be short circuited to the common terminal (AGND);

Differential signals (such as 4-20mA) require the signal source to be positively connected to CHx (+) and negatively connected to CHx (-), with a common mode voltage of ≤± 10.5V;

The shielding layer is connected to the top shielding terminal of the module to avoid the introduction of interference signals.

Fault diagnosis and maintenance

(1) LED status diagnosis

Each module panel is equipped with status LEDs, which provide feedback on the operating status through light on/off/flashing. The core interpretation is as follows:

Module type LED identification status fault cause solution

The digital input channel light (CH0-CH31) is not on, the channel is not enabled/the wiring is disconnected/the sensor is faulty. 1. Check the configuration word to enable the channel; 2. Check the wiring and sensor power supply

Flashing open circuit/overvoltage/module internal fault 1. Measure input voltage (15-30V DC required); 2. Replace the module for testing

The digital output channel light (CH0-CH31) is not on, the channel is not enabled, the load is short circuited, and the electronic protection is triggered. 1. Check the configuration word and load; 2. Restart after removing the faulty load

OB32E E-Fuse is always on, corresponding to channel short circuit/overload. 1. Disconnect the load to check the short circuit point; 2. Wait for the module to cool down and reset automatically

Analog module status light (STATUS) flashing configuration error/over range/open circuit 1. Check the configuration word (input type/filter); 2. Measure signal range

Channel lights (CH0-CH7) flashing, channel open circuit/signal over range 1. Check wiring integrity; 2. Confirm that the signal source output is normal

(2) Common troubleshooting

Module unresponsive:

Reason: Backplane power supply failure, incorrect module insertion, incorrect address configuration;

Investigation: 1 Measure the 5V/24V voltage of the rack (in accordance with module requirements); 2. Re plug and unplug the module and check the locking of the buckle; 3. Confirm that the ID code and address allocation are correct.

Digital input signal loss:

Reason: Sensor malfunction, loose wiring, electromagnetic interference;

Investigation: 1 Measure the output voltage of the sensor (must be ≥ 15V DC conduction); 2. Re tighten the terminals; 3. Increase shielding or keep away from interference sources.

The analog signal fluctuates greatly:

Reason: Poor shielding grounding, long signal cables, and no filtering configuration;

Investigation: 1 Ensure that the shielding layer is grounded at one end; 2. Shorten cables or use signal amplifiers; 3. Reduce the filtering frequency in the configuration word (e.g. set to 1Hz).

(3) Daily maintenance suggestions

Regular inspection: Clean the module and rack dust every 3 months, check the tightness of the wiring terminals to avoid looseness and poor contact;

Environmental control: Ensure that the temperature inside the control cabinet is ≤ 60 ℃ and the humidity is ≤ 95% (without condensation). Install a cooling fan in high-temperature environments;

Spare parts management: Key modules (such as 1746-NI8, OB32E) require spare parts to be reserved for quick replacement in case of failure, reducing downtime;

Software backup: Regularly backup RSLogix 500 project files (including module configurations) to avoid recovery difficulties caused by configuration loss.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Automation Module

-

HIMA K9203 PLC Module | Safety Control System Module

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

-

XYCOM CU040103500 - VME Rack System Module 4200401

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923