K-WANG

Foxboro Evo ™ FBM218 module

Foxboro Evo ™ FBM218 module

Core functions and features

(1) Output channel and signal support

Channel configuration: It has 8 isolated output channels, and each channel can flexibly choose two output modes: one is a standard 4-20mA analog output signal, and the other is to superimpose a digital HART frequency shift keying (FSK) signal on the 4-20mA analog output signal, which can be compatible with both standard 4-20mA devices and HART devices.

Communication capability: Each output channel is equipped with a dedicated FSK modem, which can achieve bidirectional digital communication with HART field devices, support HART universal commands, and ensure the connection between field devices and Foxboro Evo ™ Stable integration of the system; The system can receive 2 digital messages per second from each field device, and also supports HART universal, regular operation, and device specific instructions (excluding burst communication mode), which need to be implemented through an intelligent field device configurator (IFDC).

(2) Redundancy Design and Reliability

Module redundancy: Adopting module to module redundancy design, redundancy is achieved at the fieldbus module (FBM) level, requiring the use of redundant adapters (RH101AY). In the redundant configuration, one module serves as the "Master" and the other as the "Tracker", sharing a common terminal component (TA), greatly improving subsystem availability.

Fault response: if a module fault is detected, the output of the fault module will immediately drop to 0mA, and the corresponding channel of the normal module will be automatically connected to provide the correct current for the output current circuit to avoid on-site signal interruption; Supports multiple output safety configurable options, including fail safe actions (hold/fallback), analog output fail safe fallback data (set by channel, requiring 0mA output), fieldbus fail safe enable and delay time, and 0mA output setting can also reduce the risk of "high fault current".

Maintenance convenience: when replacing any module, it is not necessary to disconnect the field equipment terminal wiring, power supply or communication cable, nor will it affect the field signal of another module; The module is installed on the Compact 200 series substrate and only requires two screws for fixation, making disassembly and replacement operations easy.

(3) Electrical protection and isolation

Isolation performance: Galvanic isolation (including photoelectric isolation and transformer isolation) is achieved between all output channels, channels and ground, and channels and module logic, and can withstand 600V AC voltage (1 minute) without damage (note: not designed for long-term connection to this voltage level).

Power and load protection: Each channel is equipped with an independent isolated power supply, with an output current design limit of about 25mA. Even if the output field-effect transistor is short circuited, the maximum current is only 100mA. During normal operation, the module outputs a constant current to a load of 0-750 Ω to ensure equipment safety.

Design and Installation

(1) Compact and durable design

Appearance and Material: The module width is narrower than the standard 200 series FBM, and it adopts a sturdy acrylonitrile butadiene styrene (ABS) material shell to effectively protect the internal circuit; Compatible with a dedicated casing that can meet the G3 level (harsh) environmental protection requirements defined in ISA standard S71.04.

Size and Weight: The module has a height of 130mm (5.12 inches), a width of 25mm (0.98 inches), a depth of 150mm (including substrate connectors, 5.9 inches), and a weight of approximately 185g (6.5 ounces). Its compact size makes it easy to install in limited space scenarios.

(2) Installation configuration

Module installation: It needs to be installed on a Compact 200 series 16 slot horizontal substrate, which can be installed on a horizontal DIN rail or a 19 inch rack through an installation kit; Redundant modules need to be installed adjacent to the substrate, and the first module should be located in an odd numbered slot (such as slot 3 and 4), connected to the same terminal component through a redundant adapter.

Terminal Assembly (TA): TA is installed on DIN rails and compatible with various DIN rail specifications such as 32mm (1.26 inches) and 35mm (1.38 inches); We offer two types of wiring: compression type and ring type. Compression type supports solid/multi strand wires of 0.2-4mm ² (24-12 AWG), while ring type supports connectors of # 6 specification (0.5-4mm ²/22-12 AWG); TA material is polyamide (PA), with weights of approximately 181g (compression type) and 249g (ring wiring type), respectively.

Cable requirements: Terminal cables support polyurethane or low smoke halogen-free (LSZH) materials, with a maximum length of 30m (98 feet); The module end is a 37 pin D-type miniature connector, and the TA end is a 25 pin D-type miniature connector. The specific model needs to refer to Table 2 (such as the 0.5m polyurethane cable model RH100BY).

Technical specifications

(1) Functional specifications

Category parameter details

HART device compatibility supports instruments that comply with HART version 5, 6, and 7 specifications

Communication method: point-to-point, master-slave, asynchronous, half duplex, baud rate of 1200

Error detection byte level check, message level 32-bit CRC check

Analog output accuracy within 4-20mA range, ± 0.05% span (including linear error)

Output change rate can reach 20mA within 60 milliseconds

Resolution 13 bits

The maximum transmission distance complies with the HART FSK physical layer specification HCF_SPEC-54 (revised 8.1), with a maximum distance of 3030m (10000 feet). If an intrinsic safety barrier is used, the distance will be shortened

The power supply requires redundant 24V DC input, with a permissible voltage fluctuation range of+5%/-10%; Maximum power consumption 8W, maximum heat dissipation 4W

Calibration requirement module and terminal components do not require calibration

(2) Environmental specifications

Environmental condition module parameters Terminal component (PA material) parameters

Working temperature -20 to+60 ° C (-4 to+140 ° F) -20 to+70 ° C (-4 to+158 ° F)

Working humidity 5% -95% (non condensing) 5% -95% (non condensing)

Working altitude -300 to+3000m (-1000 to+10000 feet) -300 to+3000m (-1000 to+10000 feet)

Storage temperature -40 to+85 ° C (-40 to+185 ° F) -40 to+85 ° C (-40 to+185 ° F)

Storage humidity 5% -95% (non condensing) 5% -95% (non condensing)

Storage altitude -300 to+12000m (-1000 to+40000 feet) -300 to+12000m (-1000 to+40000 feet)

The anti pollution level meets the G3 level (harsh) environmental requirements of ISA standard S71.04 (based on EIA standard 364-65 level III exposure test) and meets the G3 level (harsh) environmental requirements of ISA standard S71.04 (based on EIA standard 364-65 level III exposure test)

Anti vibration performance within the frequency range of 5-500Hz, 7.5m/S ² (0.75g) within the frequency range of 5-500Hz, 7.5m/S ² (0.75g)

(3) Compliance certification

Electromagnetic compatibility (EMC): compliant with the EU EMC Directive (2004/108/EC, before April 20, 2016); 2014/30/EU, After April 20, 2016, it meets the EN61326-1:2013 Class A emission and industrial immunity level.

Environmental compliance: Compliant with the EU RoHS Directive 2011/65/EU.

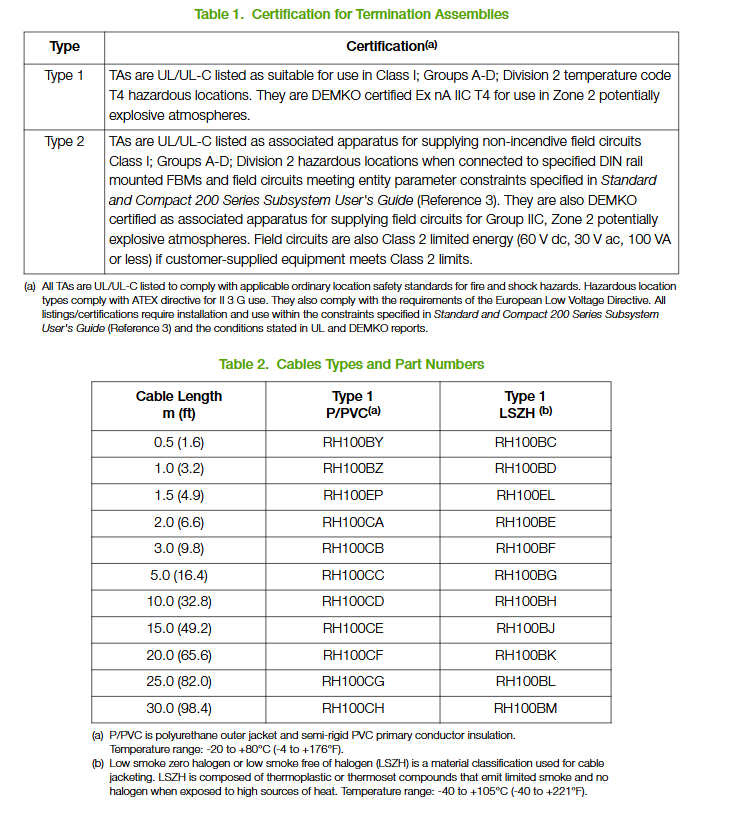

Safety certification: UL/UL-C certification, suitable for hazardous environments with Class I A-D groups, Zone 2, T4 temperature codes (requires connection to designated Foxboro Evo processor modules); The communication circuit complies with the Class 2 circuit requirements of Article 725 of the National Electrical Code (NFPA 70) in the United States and Article 16 of the Electrical Code (CSA C22.1) in Canada; Compliant with the EU Low Voltage Directive (2006/95/EC, before April 20, 2016); 2014/35/EU, After April 20, 2016, DEMKO certified Ex nA IIC T4 according to the Explosion proof Directive (ATEX) and applicable to Zone 2 hazardous environments.

**Marine Certification * *: Obtained type approval from the American Bureau of Shipping (ABS) and ship certification from the Bureau Veritas, meeting the environmental category EC31.

Related documents and component information

(1) Reference Documents

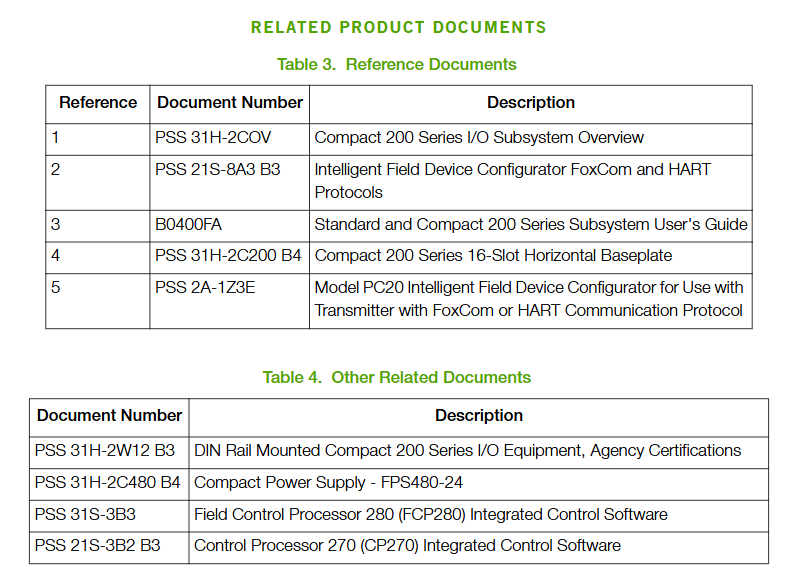

Reference Number Document Number Document Description

Overview of PSS 31H-2COV Compact 200 Series I/O Subsystem

PSS 21S-8A3 B3 Intelligent Field Device Configurator FoxCom and HART Protocol

B0400FA Standard and Compact 200 Series Subsystem User Guide

4 PSS 31H-2C200 B4 Compact 200 series 16 slot horizontal substrate

5 PSS 2A-1Z3E PC20 Intelligent Field Device Configurator (applicable to FoxCom or HART protocol transmitters)

(2) Key component model

FBM218 module: RH101AE

Redundant adapter: RH101AY

Terminal Component (TA): RH926SP (replacing old models P0926SP, P0917XV), certified as Type 1 (UL/UL-C Class I A-D Group 2 T4, DEMKO Ex nA IIC T4 Zone 2)

Terminal cables: divided into two materials: polyurethane (P/PVC, -20 to+80 ° C) and LSZH (-40 to+105 ° C), with different lengths corresponding to different models. For example, the 0.5m polyurethane cable is RH100BY, and the 0.5m LSZH cable is RH100BC (see document table 2 for the complete model list).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923