K-WANG

DeltaV ™ Flex Connect Solutions for Foxboro ™ I/A Series 100 I/O

DeltaV ™ Flex Connect Solutions for Foxboro ™ I/A Series 100 I/O

Core positioning and value

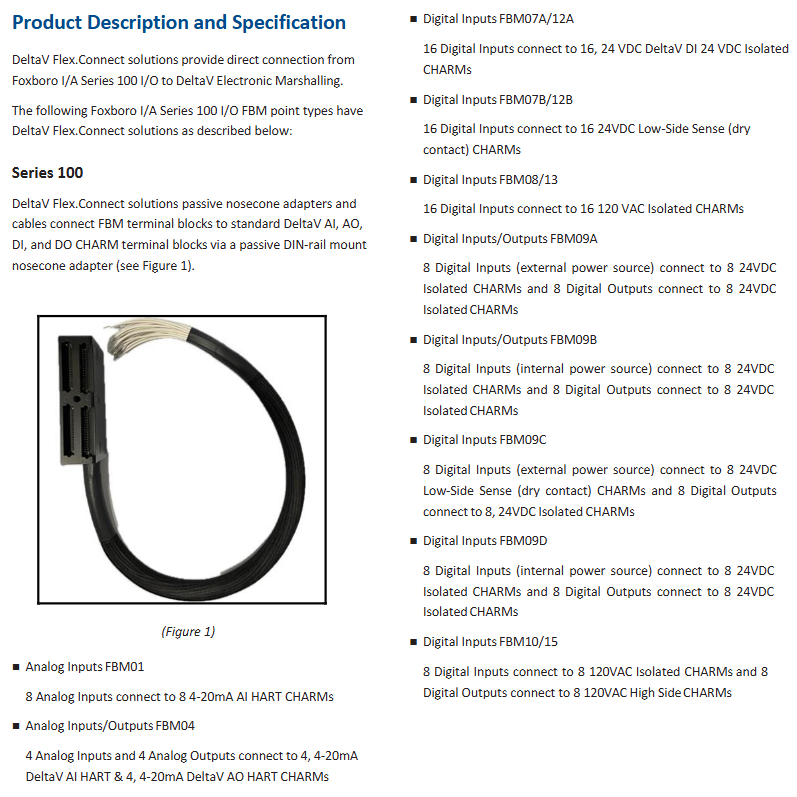

The FlexConnect solution is a modular and scalable connection solution for Foxboro I/A Series 100 I/O systems. Its core value lies in breaking the limitations of traditional I/O systems' fixed cabinet installation. Through remote/distributed connection capabilities, flexible topology configuration, and high reliability design, it adapts to the complex installation environment and diverse equipment access requirements of industrial sites (such as chemical, petroleum, power, etc.), simplifies wiring, reduces installation costs, and improves the overall maintainability and fault resistance of the system.

System architecture and core components

The FlexConnect solution adopts a layered architecture of "main controller remote I/O unit field device", with core components including remote I/O modules, communication links, terminal components, and supporting accessories. The functions and collaborative relationships of each part are as follows:

(1) Core components and functions

Component type, key model/specification, core function

The remote I/O module supports Foxboro I/A Series 100 I/O signal types (such as analog input/output, digital input/output, HART communication, etc.) 1. Local acquisition/output of field device signals (such as 4-20mA, discrete signals);

2. Implement signal isolation and anti-interference processing;

3. Bidirectional transmission of data with the main controller through a communication link.

The communication link supports redundant/non redundant Ethernet and dedicated industrial bus to ensure high-speed and stable data transmission between the main controller and remote I/O modules;

2. Redundant link design avoids communication interruptions caused by single point failures.

Terminal Assembly (TA) is a specialized terminal module that adapts to different signal types. 1. It provides physical wiring interfaces between field devices and remote I/O modules;

2. Support cable fixation and anti loosening design, suitable for different wire diameters (such as 0.2-4mm ² wires).

Power module 24V DC redundant power supply 1. Provides stable power supply for remote I/O modules and terminal components;

2. Redundant design ensures seamless switching in case of power interruption, ensuring the continuous operation of the module.

The protective casing meets the IP rating (such as IP65/IP67). 1. It protects remote I/O modules and terminal components from on-site dust, water vapor, and corrosive gases;

2. Suitable for installation in outdoor or harsh industrial environments.

(2) Topology configuration flexibility

Distributed deployment: Remote I/O units can be installed near field devices (such as equipment side or field cabinets), significantly reducing the length of cables from field devices to I/O modules (traditional solutions require cables to be pulled to the central cabinet, while FlexConnect can reduce wiring by more than 50%).

Multiple topology support: Supports various communication topologies such as star, bus, and ring, and can be flexibly selected according to the distribution density and distance of on-site devices (such as ring topology is suitable for long-distance and multi node scenarios, improving communication redundancy).

Mixed signal access: A single remote I/O unit can simultaneously access multiple types of signals such as analog, digital, and HART, without the need for separate cabinets for different signals, simplifying the system architecture.

Core functions and technical features

(1) High reliability and fault redundancy

Communication redundancy: Supports dual Ethernet links or redundant industrial buses. In the event of a main link failure, the backup link can automatically switch within milliseconds (<100ms) without data loss, ensuring process control continuity.

Power redundancy: The remote I/O unit adopts dual 24V DC power input. When a single power supply fails, the other power supply seamlessly takes over to avoid signal interruption caused by module power failure.

Module level isolation:

Galvanic isolation is implemented between each I/O channel and between channels and module logic circuits (with an isolation voltage of up to 600V AC/1 minute) to prevent module damage caused by on-site signal interference or grounding loops.

The analog channel supports independent current limitation (such as a maximum of 25mA) to avoid the impact of load short circuits on the module.

Fault diagnosis and alarm:

The module has built-in real-time diagnostic function, which can monitor channel faults, communication abnormalities, power supply voltage fluctuations and other issues, and upload alarm information to the main controller through the communication link.

Support local LED indicator light alarms (such as normal power supply, communication status, channel failure), making it easy for on-site maintenance personnel to quickly locate problems.

(2) HART communication compatibility and support for smart devices

HART protocol integration: All analog I/O modules support the HART protocol (compatible with HART 5/6/7 versions) and can overlay digital communication on 4-20mA analog signals to achieve:

Remote reading of diagnostic information, range settings, and calibration data from smart devices such as HART transmitters;

Remote configuration and calibration of on-site HART devices through the main controller, without the need for on-site operation.

HART data processing: Supports HART universal instructions, conventional operation instructions, and device specific instructions. The main controller can receive multiple digital messages from each HART device per second, meeting real-time monitoring and control requirements.

(3) Installation and maintenance convenience

Modular design:

The remote I/O module and terminal components adopt a modular structure and support "hot plugging" (some models). When replacing the module, there is no need to disconnect the on-site wiring or interrupt the system operation, reducing maintenance downtime.

The module size is compact (such as height ≤ 150mm, width ≤ 30mm), and can be installed on DIN rails or small cabinets, suitable for on-site environments with limited space.

Simplified wiring:

Remote deployment reduces the long-distance wiring of on-site equipment to the central cabinet, lowering cable costs and construction difficulties;

The terminal component supports the "one in, multiple out" wiring method, which can simultaneously connect multiple on-site devices of the same type, simplifying the wiring logic.

Configuration tool support:

Compatible with Foxboro I/A Series system configuration software (such as FoxDraw, Control Builder), remote I/O module channel parameters (such as range, alarm threshold, fault safety action) can be configured remotely through the software without on-site debugging.

(4) Environmental adaptability

Protection level: When the remote I/O unit is paired with a dedicated protective casing, the protection level can reach IP65/IP67, and it can be directly installed outdoors or in dusty, humid, and corrosive environments (such as chemical workshops and refinery sites).

Temperature and humidity range:

Working temperature: -20 ° C to+60 ° C (some models support a wide temperature range of -40 ° C to+70 ° C);

Working humidity: 5% -95% (non condensing), suitable for high humidity industrial environments;

Anti vibration performance: Within the frequency range of 5-500Hz, it operates stably under a vibration intensity of 7.5m/S ² (0.75g), meeting the requirements of industrial site vibration environment.

Detailed explanation of technical specifications

(1) Electrical and Communication Specifications

Specification category parameter details

Power requirement input voltage: 24V DC (allowable fluctuation range:+5%/-10%);

Maximum power consumption: Single module ≤ 8W, redundant configuration ≤ 16W.

Communication rate Ethernet link: 10/100Mbps adaptive;

Industrial bus: Depending on the bus type, it can reach 1Mbps (such as Profibus DP).

Signal type supports analog input (AI): 4-20mA, 1-5V;

Analog output (AO): 4-20mA;

Digital input (DI): dry contact, 24V DC wet contact;

Digital Output (DO): Relay output, 24V DC transistor output.

HART performance baud rate: 1200bps (half duplex);

Support message types: general instructions, general operation instructions, device specific instructions;

Data verification: 32-bit CRC verification to ensure communication accuracy.

Isolation performance between channels: 600V AC/1 minute;

Channel and ground isolation: 600V AC/1 minute;

Power and logic isolation: 500V AC/1 minute.

(2) Environmental and mechanical specifications

Specification category parameter details

Working temperature standard type: -20 ° C to+60 ° C;

Wide temperature range: -40 ° C to+70 ° C.

Storage temperature -40 ° C to+85 ° C (non condensing).

Working humidity 5% -95% RH (without condensation, temperature ≤ 40 ° C).

Protection level module bare machine: IP20 (to be installed in the cabinet);

Equipped with protective casing: IP65/IP67 (can be installed outdoors).

Installation method: DIN rail installation (compatible with 35mm standard rail);

Fixed installation of cabinet screws.

Module size (example) height: 130mm (5.12 inches);

Width: 25mm (0.98 inches);

Depth: 150mm (5.9 inches);

Weight: Approximately 200g (7.05 ounces).

(3) Compliance certification

Electromagnetic compatibility (EMC): Complies with the EU EMC Directive (2014/30/EU), meets the Class A emission requirements and industrial immunity levels (anti-static, radio frequency interference, electrical fast transient pulse group, etc.) of EN 61326-1:2013 standard.

Security certification:

UL/UL-C certification: suitable for hazardous environments with Class I A-D groups, Zone 2, T4 temperature codes (with designated Foxboro I/A Series controllers);

ATEX certification: Ex nA IIC T4 Ga, suitable for Zone 2 hazardous environments;

IECEx certification: Compliant with IEC 60079-15 standard, suitable for global hazardous area applications.

Environmental compliance: Compliant with the EU RoHS Directive (2011/65/EU), restricting the use of harmful substances such as lead, mercury, cadmium, etc;

Marine certification: Some models have been certified by American Bureau of Shipping (ABS) and Bureau Veritas, and are suitable for marine environments such as ship power systems and offshore platforms.

Application scenarios and supporting documents

(1) Typical application scenarios

The FlexConnect solution is mainly suitable for industrial process automation scenarios of Foxboro I/A Series 100 I/O systems, especially for the following needs:

In scenarios where on-site equipment is dispersed, such as large chemical parks and refineries, where equipment is distributed over a wide area, remote I/O deployment can reduce long-distance wiring costs;

Adverse environmental scenarios: such as outdoor storage tank areas, high temperature/high humidity workshops, modules with IP65/IP67 protective enclosures can be directly installed without the need for additional protective cabinets;

High reliability requirements scenarios: such as power systems, oil platforms, redundant communication and power supply design to ensure uninterrupted process control;

Intelligent device intensive scenarios: such as process industries equipped with a large number of HART transmitters, the solution can efficiently integrate HART digital communication to achieve remote management of intelligent devices.

(2) Key reference documents

Document Number Document Name Core Content

PSS EN 67866 FlexConnect Solutions Product Data Sheet Overview, Core Component Specifications, Technical Parameters, Certification Information;

Foxboro I/A Series 100 I/O User Guide Foxboro I/A Series 100 I/O User Guide 100 I/O System Basic Operations, Module Configuration Methods, Fault Diagnosis Process;

FlexConnect Installation Manual: Installation steps, wiring specifications, and debugging guidelines for remote I/O modules, terminal components, and protective enclosures;

HART Communication Guide for Foxboro I/A Series Foxboro I/A Series HART Communication Guide: Steps for HART Device Access Configuration, Data Reading, and Remote Calibration Operations.

Core differences from traditional I/O solutions

Comparison Dimension FlexConnect Solution Traditional Foxboro I/A Series 100 I/O Solution

Deployment method: remote/distributed deployment, centralized deployment near on-site equipment, all cables need to be pulled to the central cabinet

Reduce wiring costs by more than 50%, reduce cable and construction costs for long-distance wiring, which is costly and complex to construct

The maintenance efficiency module supports hot plugging, local LED alarms, and quick fault location. It requires opening the central cabinet for maintenance, and fault diagnosis relies on controller data

Environmental adaptability supports IP65/IP67 protection and is suitable for harsh/outdoor environments. It relies on central cabinet protection and cannot be directly exposed to harsh environments

Redundancy capability: Communication and power dual redundancy, with millisecond level fault switching. Only some core modules support redundancy, and communication redundancy requires additional configuration

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923