K-WANG

YOKOGAWA STARDOM FCN-100/FCJ Migration Technology

YOKOGAWA STARDOM FCN-100/FCJ Migration Technology

Migration core process

1. Data migration (general process)

Step operation command/tool key instructions

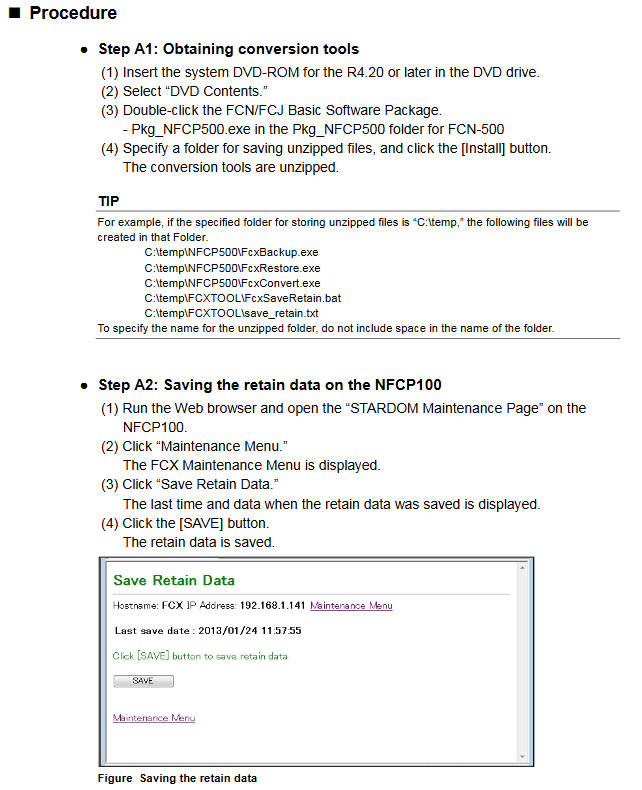

Backup and export NFCP100/NFJT100 data, FcxBackup all - u<username>- p<password><IP/hostname>, generate a "ACKUP" folder containing resource configuration, DUONUS.PRP, etc

Convert to NFCP500 format FcxConvert - t<NFCP501/NFCP502>- i<source folder>- o<destination folder>NFJT100 backup file cannot be converted, I/O needs to be reset

Before restoring the import of NFCP500 FcxRestore<IP/hostname>, the target folder needs to be renamed to "ACKUP" and the SRAM cleared to preserve data

Assist in clearing and holding data FcxSaveRetain-c<IP/hostname>to ensure that the backed up data is correctly mapped to SRAM

2. Control application migration

Project upgrade: R1-R3 format project automatically converts to R4 format after opening, R4 project is not backward compatible

Resource reconstruction rules (by PLC type):

Notes on PLC type processor type migration operation

IPC_40 FCX/FCX_A can be recompiled directly without modifying the project

IPC40 FCX_B/FCX_C reconstruction resources (IPC40+FCX_B/FCX_C)+compilation extension to maintain data area usage

IPC_32/IPC_33- Rebuilding resources (PLC type changed to IPC_40)+Definition of tasks/variables/labels to be copied for compilation

SH_40- Rebuilding resources (changing PLC type to IPC_40)+compiling compatible with existing functions

Download requirements: Offline download of the control application is required, and the startup project and source files should be downloaded as needed

3. Comparison of two migration modes

Advantages of core steps in applicable scenarios

Directly migrating to the on-site environment is simple and does not require pre validation of A1 (acquisition tool) - A10 (APC execution). The 10 step process is concise and does not require internal device support

The pre migration site environment is complex, and it is necessary to verify the site (B1-B3) → internal (B4-B10) → site (B11-B16) in advance, with a total of 16 steps to reduce the risk of on-site downtime and identify problems in advance

Special configuration migration

1. New feature settings (exclusive to NFCP500)

Need to configure through Resource Configurator: CPU dual machine hot standby, SNTP server, 3/4 Ethernet port of NFCP502, SD card, Duolet function

NFJT100 migration requires additional I/O definition settings

2. Field bus migration (NFLF111/NFLP121/NFLC121 modules)

Need to copy and import configuration files: FOUNDATION field bus (CF/DD file), PROFIBUS (GSD file), CANopen (EDS file)

Original project PC → New project PC: Export resource configuration → Import configuration → Download to NFCP500

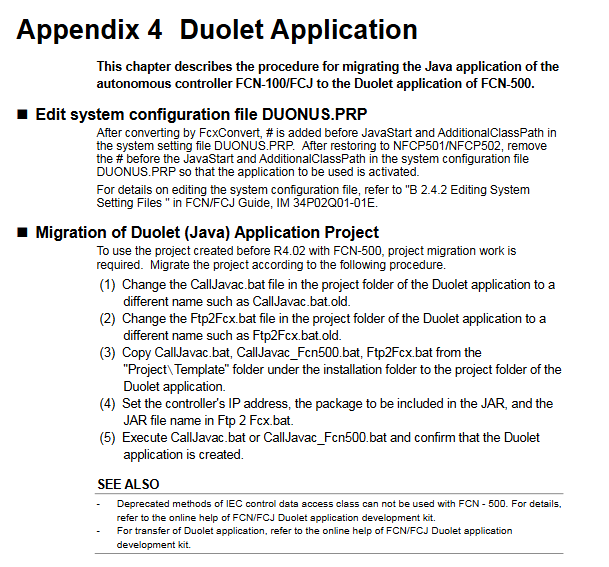

3. Duolet (Java) application migration

Edit DUONUS.PRP: Remove the "#" comment before JavaStart and AdditionalClassPath

Replace batch files: CallJavac.bat, Ftp2Fcx.bat (copied from installation directory template)

Configuration parameters: Set controller IP, JAR package information, perform compilation validation

Key Limitations and Precautions

License: Cannot be migrated from the original device, NFCP500 CPU module with pre bundled required license must be used

Keep data: When expanding the hold data area, the hold data saved by the original NFCP100 is unavailable

Port adaptation: The COM2 of FCJ needs to be migrated to the RS-232C communication module, and the port name in the program needs to be changed to "RS02", etc

Dual machine hot standby: The control side and standby side CPUs must be of the same model and have the same basic software version. After migration, APC must be executed

Key issues

Question 1: What are the differences in core operations for different PLC types (IPC32/33/40) when controlling application migration?

answer:

IPC40 (processors FCX/FCX_A): No project modification required, simply recompile to adapt to NFCP500; If you need to expand and maintain the data area, you need to rebuild the resources as "IPC40+FCX_B/FCX_C" and compile them.

IPC32/IPC33: It is necessary to rebuild the resources (change the PLC type to IPC40), and copy the task definitions, global variables, device labels, software wiring, and other configurations of the original project before compiling and downloading.

The core difference lies in whether resources need to be rebuilt. The root cause is that NFCP500 is only compatible with IPC40 and above PLC types, and lower version PLC types need to be upgraded and adapted.

Question 2: What are the applicable scenarios and core differences between the two migration modes (direct migration vs pre migration)?

answer:

Applicable scenarios: Direct migration is suitable for scenarios where on-site downtime is allowed and the environment is simple (without complex field buses or special applications); Pre migration is suitable for complex on-site environments (including field buses and Duolet applications) that require minimizing downtime risks.

Core difference: Pre migration adds an "internal device verification" step (steps B4-B10), which allows for early completion of data conversion, application compilation, and functional testing. On site, only CPU replacement, data recovery, and application download need to be performed; Direct migration means that all operations are completed on the target device on site without pre validation, resulting in a simpler process but higher risks.

Question 3: How to migrate the configuration of the field bus module (NFLF111/NFLP121/NFLC121) during the migration process? What should I pay attention to?

answer:

Migration steps: ① Export field bus definition information from the original project PC (NFCP100); ② Copy the configuration files (CF/DD/GSD/EDS) to the new project PC (NFCP500); ③ Import definition information and download it to NFCP500; ④ Verify the field bus communication function.

Attention: ① If using FF engineering tools before R2.20, the configuration needs to be converted to FF configurator format first; ② The field bus definition information is bound to the controller IP, and when replacing the project PC, "export import" must be performed. Upgrading the same PC does not require any operation; ③ After migration, it is necessary to focus on verifying the communication connectivity of field bus devices to avoid configuration omissions.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923