K-WANG

YOKOGAWA FA-M3 Embedded Machine Controller

YOKOGAWA FA-M3 Embedded Machine Controller

System core configuration

1. Module composition

Basic modules: 6 models (F3BU04-0N to F3BU16-0N), 4-16 slots, supporting different module combinations

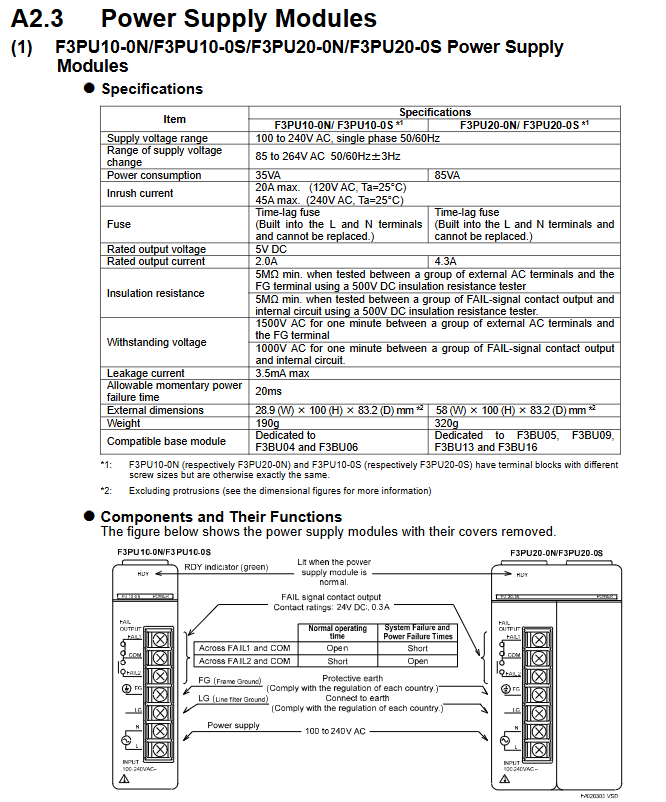

Power module: AC input (F3PU10/20/30 series), DC input (F3PU16/26/36 series), output voltage 5V DC, rated current 2.0A-6.0A

CPU module: including sequential CPU, BASIC CPU, OS free CPU, etc., instruction execution time 0.00375 μ s-0.36 μ s/step, program capacity 5K-254K steps

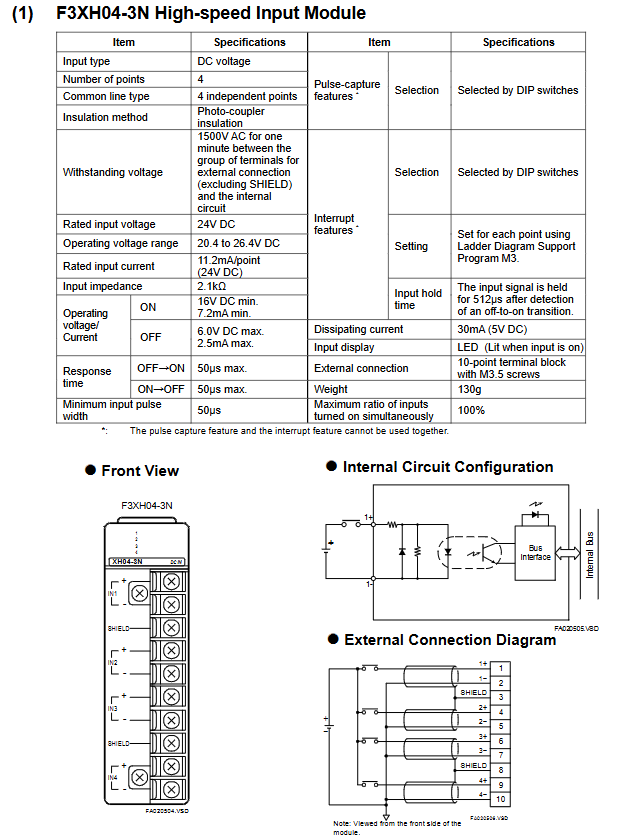

I/O modules: digital (input/output/hybrid), analog (input/output), special modules (temperature control, positioning, communication, etc.), with 8-64 points per module

Expansion modules: Fiber FA bus module, communication module (Ethernet, PROFIBUS-DP, etc.)

2. System topology

Main unit: Must contain 1 CPU module, unit number 0, supports up to 3 extended CPU modules

Slave unit: No CPU module, up to 7, connected to the main unit through a bus, with a maximum of 8192 I/O points per system

Expansion distance: The maximum length of a single section of fiber optic cable is 500m, and the maximum length of a twisted pair cable is 70m

Key technical parameters

1. Environmental and physical parameters

Category specifications

Working temperature 0-55 ℃ (some modules require a narrower range)

Storage temperature -20-75 ℃

Relative humidity 10-90% RH (non condensing)

Installation requirements for indoor use, metal panel enclosure (IK08 and above)

The highest altitude is 2000m

Anti vibration 10-57Hz amplitude 0.075mm, 57-150Hz acceleration 9.8m/s ²

2. Electrical parameters

Power supply fluctuation: AC power supply 85-264V, DC power supply 15.6-31.2V

Insulation resistance: ≥ 5M Ω (tested at 500V DC)

Voltage resistance strength: 1500V AC/1 minute (power terminal - ground)

Leakage current: ≤ 3.5mA (AC power supply)

Allow instantaneous power outage: up to 20ms (standard mode)

3. Performance indicators

CPU processing speed: Basic instructions 0.0175 μ s-0.36 μ s/step (depending on model)

I/O response time: The fastest digital quantity is 50 μ s, and the fastest high-speed module is 0.1ms

Communication speed: Ethernet up to 100Mbps, PROFIBUS-DP up to 12Mbps

Scalability: Supports up to 7 slave units and 32 FA link H module sites

Installation and wiring specifications

1. Installation requirements

Fixing method: DIN rail installation (F3BU04/06/05/09/13) or M4 screw fixation (all models)

Installation gap: Vertical installation spacing ≥ 8cm, unobstructed upper and lower ventilation openings

Module installation: Power off operation, the module needs to be clamped to the locking buckle, and additional screws are required to fix it in the vibration environment

2. Wiring specifications

Conductor requirements: Only copper conductors are allowed, with a cross-sectional area of 0.33-2.1mm ² (AWG14-22)

Terminal torque: M3 screw 0.8N · m, M4 screw 1.2N · m

Anti interference measures:

The distance between signal cable and power cable is ≥ 20cm

Analog signal and digital signal slot wiring

Shielded cable with both ends grounded, bending radius ≥ 50mm (fiber optic)

Grounding requirements:

Protective grounding (FG): connected to the protective grounding grid, cable ≥ 2mm ²

Functional grounding (FG): low impedance grounding, CE compliant requires braided wire

3. CE certification compliance requirements

Electromagnetic compatibility (EMC): EN 61326-1 Class A, EN 55011 Class A

Low Voltage Directive (LVD): EN 61010-1, Overvoltage Category II

RoHS compliance: EN IEC 63000 standard

Testing and Maintenance

1. Testing process

Installation inspection: The module is securely installed and the panel is well ventilated

Wiring inspection: correct polarity, terminal tightening, shielding layer grounding

Insulation test: 500V DC megohmmeter, insulation resistance ≥ 5M Ω

Power on test: If the power indicator light (RDY) is constantly on, it is normal

Functional testing: Safety circuit (emergency stop) → Single module testing → System linkage testing

2. Maintenance points

Regular maintenance: clean panel (soft cloth+neutral cleaner), check cable connections

Spare parts replacement:

Battery: The serial CPU module is equipped with a built-in lithium battery, which has a lifespan of ≥ 10 years at room temperature

Module: Preventive replacement is required after more than 10 years of use

Fuse: 3.15A Delay Fuse (Model A1113EF)

Fault handling: Check the error code through the CPU self diagnostic function. Core errors include module communication failure, power supply abnormality, I/O short circuit, etc

Safety precautions

Power off operation: The power must be turned off before wiring or plugging in modules

Prohibition of modification: It is not allowed to modify the internal circuit or shell of the module

Load limit: The output module must not exceed the rated current (transistor type 0.1A-2A/point, relay type 2A/point)

Environmental protection: Avoid corrosive gases, flammable gases, and radioactive environments

Emergency circuit: An external relay is required to achieve interlocking of the emergency stop circuit

Key questions and answers

Question 1: What is the maximum scalability of the FA-M3 controller? What extension methods are supported?

answer:

Maximum Expansion: The main unit (No. 0) can connect up to 7 slave units (No. 1-7), with a maximum of 8192 I/O points per system (depending on the CPU module model)

Expansion method:

Fiber optic FA bus type 2 module: using fiber optic cables, with a maximum length of 500m per section, strong anti-interference ability

FA bus type 2 module: using shielded twisted pair cables, with a maximum length of 70m per segment, at a lower cost

Local expansion: The basic module supports 4-16 slots, allowing for direct expansion of local I/O modules

Question 2: What are the key requirements for grounding and anti-interference when installing the FA-M3 controller?

answer:

Grounding requirements:

Protective grounding (FG terminal): connected to a protective grounding grid that meets national standards, with a grounding resistance of ≤ 100 Ω and a cable cross-sectional area of ≥ 2mm ²

Functional grounding (FG terminal): To ensure stable operation, grounding is necessary, and CE compliance requires the use of braided wire to ensure high frequency and low impedance

Shielding layer grounding: The two ends of the signal cable shielding layer are grounded and fixed to the metal panel through FG fixtures

Anti interference requirements:

Cable separation: The distance between power cables and signal cables should be ≥ 20cm, and analog and digital signals should be routed in separate slots

Cable selection: Use shielded twisted pair or fiber optic cables to avoid parallel laying with power cables

Filtering measures: The power module is equipped with a built-in noise filter, and sensitive modules can be additionally equipped with ferrite cores

Question 3: What are the types of power modules for the FA-M3 controller? How to choose a suitable power module?

answer:

Power module type:

Type Model Series Input Voltage Rated Output Applicable Basic Module

AC input F3PU10/20/30 100-240V AC 5V DC, 2.0A/4.3A/6.0A F3BU04/06 (10 series); F3BU05/09/13/16 (20/30 series)

DC input F3PU16/26/36 24V DC 5V DC, 2.0A/4.3A/6.0A F3BU04/06 (16 series); F3BU05/09/13/16 (26/36 series)

Selection principle:

Based on the basic module model: 4/6 slot basic module selects 10/16 series, 5/9/13/16 slot selects 20/26/30/36 series

According to power requirements: total current consumption ≤ rated output current of the power supply (all module current consumption needs to be added)

According to the installation environment: CE compliance requires selecting models with the suffix "S" (such as F3PU10-0S)

Based on power supply stability: AC input module is preferred for scenarios with large fluctuations (allowing 85-264V wide range)

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923