K-WANG

Yokogawa STARDOM FCN-500 Autonomous Controller

Process control: supports continuous control (PID regulation, ratio control), sequential control (logical interlocking, step control), and adapts to complex industrial processes (such as temperature control of chemical reaction vessels and pressure regulation of oil and gas pipelines);

Data acquisition and measurement: Real time acquisition of analog quantities (4-20mA, RTD/TC temperature signals), digital quantities (24V DC switch signals), and pulse quantities (frequency/pulse counting), with a measurement accuracy of ± 0.1% FS, meeting industrial grade metrology requirements;

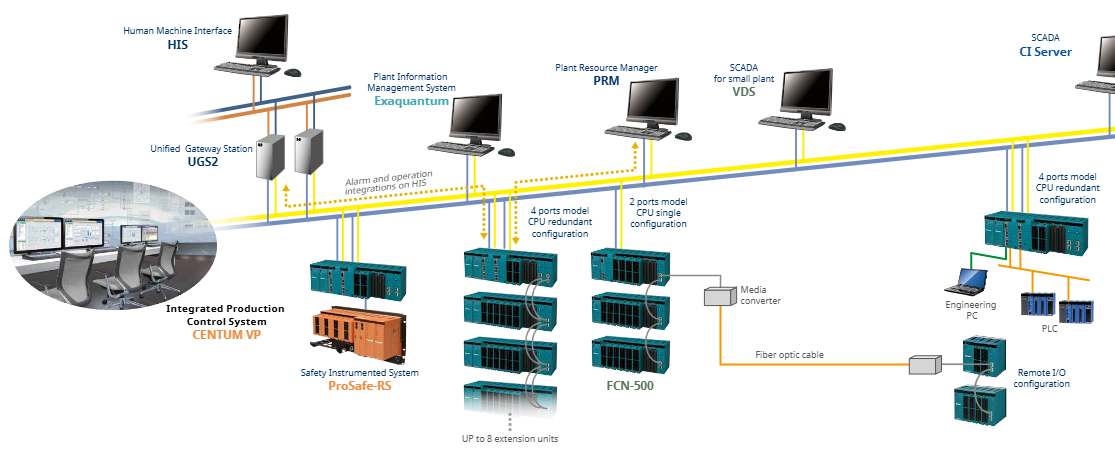

Multi protocol communication: compatible with mainstream industrial buses such as FOUNDATION Fieldbus, HART, Modbus, PROFIBUS-DP, CANopen, etc., supporting interconnection with Yokogawa CENTUM VP DCS, ProSafe RS safety systems, and third-party SCADA (such as Schneider and Siemens systems);

High reliability design: Key components (CPU, power supply, communication bus) support redundant configuration, module hot plugging, wide temperature environment adaptation (-20~+70 ℃ optional), meeting the uninterrupted operation requirements of industrial sites.

Yokogawa STARDOM FCN-500 Autonomous Controller

Product core positioning and applicable scenarios

1. Core functional positioning

FCN-500 is a multifunctional autonomous controller launched by Yokogawa, integrating the four core capabilities of "control, measurement, communication, and diagnosis". It aims to replace traditional PLCs and discrete control devices, and achieve centralized management of distributed processes. Its specific functions cover:

Process control: supports continuous control (PID regulation, ratio control), sequential control (logical interlocking, step control), and adapts to complex industrial processes (such as temperature control of chemical reaction vessels and pressure regulation of oil and gas pipelines);

Data acquisition and measurement: Real time acquisition of analog quantities (4-20mA, RTD/TC temperature signals), digital quantities (24V DC switch signals), and pulse quantities (frequency/pulse counting), with a measurement accuracy of ± 0.1% FS, meeting industrial grade metrology requirements;

Multi protocol communication: compatible with mainstream industrial buses such as FOUNDATION Fieldbus, HART, Modbus, PROFIBUS-DP, CANopen, etc., supporting interconnection with Yokogawa CENTUM VP DCS, ProSafe RS safety systems, and third-party SCADA (such as Schneider and Siemens systems);

High reliability design: Key components (CPU, power supply, communication bus) support redundant configuration, module hot plugging, wide temperature environment adaptation (-20~+70 ℃ optional), meeting the uninterrupted operation requirements of industrial sites.

2. Typical Applicable Scenarios

Petrochemical industry: used for reactor and distillation tower control in refining equipment, supporting linkage with HART intelligent valve positioner and Fieldbus analyzer to achieve precise adjustment of process parameters;

Energy industry: Suitable for monitoring of combiner boxes in wind and photovoltaic power plants, or logical control of auxiliary equipment (such as feedwater pumps and fans) in thermal power plants, supporting narrow bandwidth communication such as GPRS/satellite;

Water treatment and environmental protection: As the control unit for aeration tanks and sedimentation tanks in sewage treatment plants, it integrates flow calculation (AGA standard), liquid level regulation functions, and supports data exchange with online water quality monitoring instruments;

Distributed industrial scenario: suitable for cross regional pipeline network monitoring (such as natural gas long-distance pipelines), extending remote I/O through E2 bus to achieve centralized management of distributed units within 800 meters.

Key technical specifications and performance parameters

1. Hardware core specifications

Category core parameters (universal model, specific module slightly different)

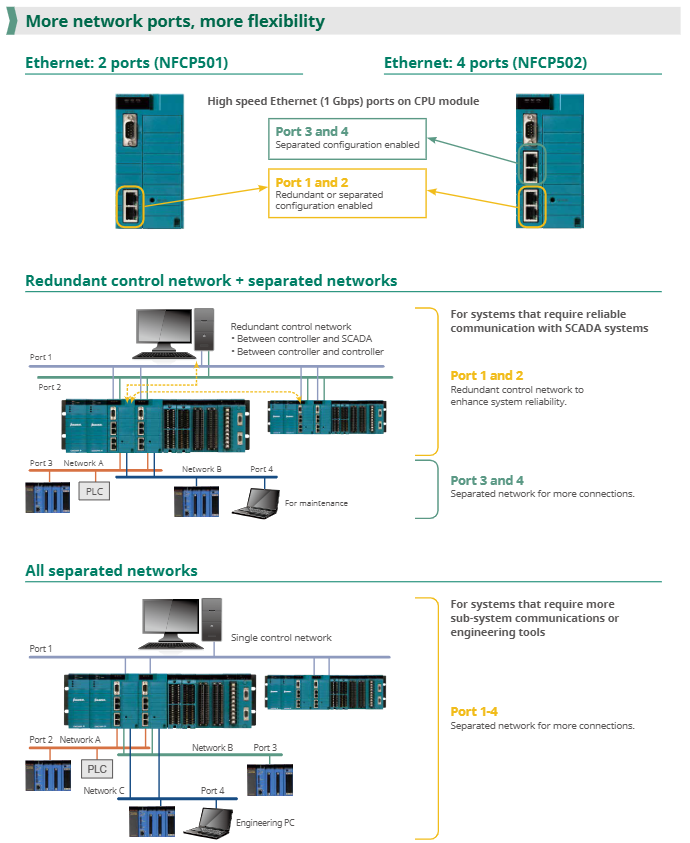

CPU module model: NFCP501 (2-channel Ethernet)/NFCP502 (4-channel Ethernet); Processor: Atom E3815 1.46 GHz; Memory: 256 MB ECC RAM (error correcting)+1 GB flash memory

Power module input: 100-120V AC/220-240V AC/24V DC; Output: 5.1V DC 7.8A (system power supply)+24V DC 4A (field equipment power supply), supporting redundant configuration

I/O module type analog input (AI): 4-20mA, 1-5V, RTD (platinum resistance), TC (thermocouple), 8-16 channels, channel isolation/non isolation optional;

Analog output (AO): 4-20mA, -10~+10V, 4-16 channels;

Digital I/O (DI/DO): 24V DC 32-64 channels, relay output (24-125V DC/100-240V AC) 16 channels

Expansion capability supports E2 bus expansion of 8 remote I/O units, with a maximum transmission distance of 800 meters per line (fiber optic expansion can reach 5 kilometers); A single controller can support up to 79 I/O modules

2. Control and communication performance

Control cycle: minimum 5ms task scan, supports 16 priority tasks, meets fast response scenarios (such as motor start stop interlock);

Communication interface: Standard configuration includes 2/4 1Gbps Ethernet (supporting redundant/independent network configuration), 1 RS-232/485 (Modbus RTU), and optional FOUNDATION Fieldbus/PROFIBUS-DP communication module;

Protocol support:

Upper computer: OPC DA 2.05a, DNP3, Modbus TCP;

Fieldbus: FOUNDATION Fieldbus (31.25 kbps), HART 7.0, PROFIBUS-DP (12Mbps);

Time synchronization: SNTP client/server ensures distributed unit time consistency.

3. Environmental and compliance characteristics

Environmental adaptability: Operating temperature range of 0-55 ℃ (standard)/-20~+70 ℃ (wide temperature range optional); Relative humidity ranging from 5% to 95% (without condensation); Anti vibration level 5g (10-500Hz, IEC 60068-2-6);

Protection and certification: The module shell has a protection level of IP20 (installed inside the cabinet) and supports G3 anti-corrosion coating (optional); Compliant with CE, UL 508, ATEX Zone 2 (some models) certification, suitable for hazardous areas.

System configuration and expansion logic

1. Hardware architecture and redundancy design

FCN-500 adopts a distributed architecture of "control unit+expansion unit", with key components supporting redundant configuration to ensure high system availability:

Control unit: including CPU module, power module, basic I/O module, supporting 19 inch rack installation or DIN rail installation, providing three types of bases: long (NFBU200, up to 8 modules), short (NFBU050, up to 3 modules), and compact (N2BU030, 1 module), suitable for different installation spaces;

Expansion unit: Connected to the control unit through the E2 bus, each control unit can expand up to 8 expansion units, supporting mixed base configuration (long+short) to achieve flexible expansion of I/O points;

Redundant configuration: CPU, power supply, E2 bus, and Ethernet can all be redundant, with a redundancy switching time of less than 100ms to ensure seamless switching in case of faults.

2. Typical System Topology Example

plaintext

[Upper System] ← Ethernet (Modbus TCP) → [FCN-500 Control Unit (Redundant CPU+Power Supply)]

↓ (E2 bus)

[Extension Unit 1 (AI/AO module)] ←→ [On site sensors/actuators]

↓

[Expansion Unit 2 (DI/DO Module)] ←→ [Valve/Pump Control Circuit]

↓

[Expansion Unit 3 (Fieldbus Module)] ←→ [HART/Fieldbus Smart Devices]

Engineering development and operation characteristics

1. Programming and configuration tools

FCN-500 comes with Yokogawa Engineering Tool Kit, supporting IEC 61131-3 standard programming language to reduce development difficulty:

Logic Designer: a control program development tool that supports five languages: FBD (Function Block Diagram), LD (Ladder Diagram), ST (Structured Text), SFC (Sequential Function Diagram), and IL (Instruction List). It provides drag and drop programming and template libraries (such as PID control blocks and flow calculation blocks);

Resource Configurator: a hardware configuration tool that maps logical I/O to physical modules, supports IP address and communication protocol parameter settings, and does not require manual driver writing;

Simulator function: Supports hardware free debugging, can simulate control logic and I/O signals on a PC, and shorten the on-site debugging cycle.

2. Operations and diagnostic capabilities

Module hot plugging: All I/O modules and power modules support online replacement, and the configuration is automatically loaded after replacement without the need for system shutdown;

Status monitoring: The CPU module comes with an LCD display screen and LED indicator lights, which display the system status (running/faulty) and I/O module health in real time; Support exporting logs (fault records, operation records) through SD card without the need to connect to a PC;

Remote operation and maintenance: Remote diagnosis can be achieved through Web HMI or Yokogawa PRM (Plant Resource Manager) system, supporting I/O channel fault location, module firmware online upgrade, and reducing on-site maintenance costs.

Key modules and selection information

1. Core module model and function

Module Type Model Example Core Functions

CPU module NFCP501 (2 Ethernet ports) with 2 Gigabit Ethernet channels, supporting Modbus/DNP3 protocols, with optional single/redundant configurations

NFCP502 (4 Ethernet ports) 4 Gigabit Ethernet channels, supporting independent network partitioning (such as control network+operation and maintenance network)

Power module NFPW441 (100-120V AC) system power supply (5.1V DC)+on-site power supply (24V DC), supports redundancy

NFPW444 (24V DC) DC input power supply, suitable for industrial 24V DC bus power supply scenarios

Analog input module NFAI135 (8 channels) 4-20mA input, channel isolation, accuracy ± 0.1% FS, supports HART protocol

NFAR181 (12 channel) RTD input (platinum resistance 100 Ω/1000 Ω), supports wire breakage detection

Digital output module NFDV551 (32 channels) 24V DC output, channel isolation, supports fail safe output (Fallback)

NFDR541 (16 channel) relay output (24-125V DC/100-240V AC), suitable for high-power loads (such as motor contactors)

Communication module NFLF111 (4-port) FOUNDATION Fieldbus communication, supporting 16 devices per port

NFLP121 (1 port) PROFIBUS-DP master station, supporting 123 slave devices

Expansion bus module N2EB100 E2 bus interface module, realizing the connection between control unit and expansion unit, supporting redundancy

2. Key dimensions for selection

Control scale: Select the base type (long/short/compact) and the number of expansion units based on the number of I/O points. A single system can support up to 79 I/O modules;

Environmental requirements: Standard temperature modules (0-55 ℃) are selected for conventional environments, wide temperature models (-20~+70 ℃) are selected for low/high temperature scenarios, and G3 coating is optional for corrosive environments;

Communication protocol: Select the communication module based on the type of on-site equipment (such as selecting NFAI135 AI module for HART devices and NFLF111 module for Fieldbus devices);

Reliability requirements: For critical scenarios (such as chemical reaction control), CPU, power supply, and E2 bus redundancy should be configured. For non critical scenarios (such as regular monitoring), menu configuration is available.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923