K-WANG

ABB REF54 series relay protection device

ABB REF54 series relay protection device

This document is a technical document released by ABB for the REF54 series relay protection devices (presumably protection devices for medium and low voltage distribution systems, such as REF541, REF542, etc.). The core revolves around the functional characteristics, technical specifications, configuration logic, and application scenarios of the devices, aiming to guide electrical engineers in selecting devices, setting parameters, installing, debugging, and operating to ensure reliable protection of transformers, busbars, feeders, and other equipment in distribution networks (such as industrial plants, commercial buildings, and power distribution stations), in compliance with international relay protection standards such as IEC 60255.

Product core positioning and applicable scenarios

1. Core functional positioning

The REF54 series is a multifunctional digital relay protection device launched by ABB, integrating the four core functions of "protection, control, measurement, and communication". It can replace traditional discrete protection relays and measurement instruments, achieve comprehensive monitoring and rapid response to faults of distribution equipment, and cover specific functions:

Protection function: Provides overcurrent protection (inverse time limit/definite time limit), overload protection, ground fault protection, short circuit protection, undervoltage/overvoltage protection, etc. for different protected objects (transformers, feeders, busbars), supports protection setting grading (adapted to different operating conditions).

Control function: Supports local/remote operation (such as circuit breaker opening and closing, constant value switching), has operation locking logic (to prevent misoperation), and can be connected to external control signals (such as PLC, SCADA system instructions).

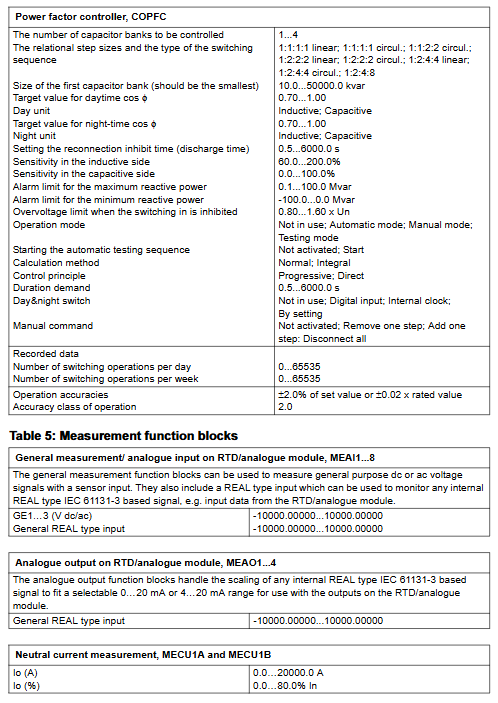

Measurement function: Real time collection of electrical parameters, including three-phase current, voltage, power (active/reactive), power factor, and electrical energy (cumulative/instantaneous), with a measurement accuracy of 0.2 level (compliant with IEC 60688 standard).

Event recording: Automatically record fault events (fault type, occurrence time, fault time parameters), operation records (opening and closing operations, constant value modification), storage capacity supports ≥ 1000 events, facilitating fault traceability and operation and maintenance analysis.

2. Typical Applicable Scenarios

Industrial power distribution: used for the protection of factory workshop power distribution circuits and motor control circuits, adapted to high load, multi start stop industrial environments, and supporting linkage with ABB AC500 and other PLC systems;

Commercial and civil buildings: As feeder protection devices for office buildings and residential distribution stations, they achieve overload and short circuit protection for lighting, air conditioning, and other loads;

Power distribution network: used for low-voltage protection of transformers in 10kV/0.4kV distribution stations, in conjunction with ABB SCADA system to achieve remote monitoring and unmanned operation.

Key technical specifications and performance parameters

1. Electrical and protective characteristics

Category core specifications (general reference, specific models may vary slightly)

Input parameter current input: 5A/1A (standard CT secondary current); Voltage input: 100V/220V (PT secondary voltage, line voltage/phase voltage optional); Frequency: 50/60Hz (automatic recognition)

Protection range for overcurrent protection: 0.1-10Ie (Ie is the rated current); Overload protection: 0.5-1.5Ie; Ground fault protection: 0.05-5Ie; Action time limit: 0.01-300s

Measurement accuracy current/voltage: ± 0.2%; Power/electric energy: ± 0.5%; Frequency: ± 0.01Hz

Trip outlet 2-4 sets of normally open/normally closed relay contacts (rated load: 5A@250VAC /30VDC), Support self checking of trip circuit (to avoid contact adhesion causing misoperation)

2. Communication and interface characteristics

Communication interface: Standard configuration includes 1 RS485 (supporting Modbus RTU protocol), optional 1 Ethernet (Ethernet/IP or Modbus TCP), supporting interconnection with upper computer (such as ABB MicroSCADA system), HMI or third-party control system to achieve data upload and remote control;

Local interface: Equipped with an LCD display screen (128 × 64 pixels, supporting Chinese/English display), 4 operation buttons (for setting settings and event queries), and some models come with a USB interface (for data export and firmware upgrade).

3. Environmental and compliance characteristics

Environmental adaptability: working temperature -25~+70 ℃ (wide temperature design), storage temperature -40~+85 ℃; Relative humidity ranging from 5% to 95% (without condensation); Anti vibration level 5g (10-500Hz, compliant with IEC 60068-2-6), suitable for complex environments inside distribution cabinets;

Compliance certification: Complies with IEC 60255 (General Standard for Relay Protection Devices), IEC 61000-6-2 (Electromagnetic Immunity for Industrial Environments), CE certification, UL 508 certification, and some models have passed ATEX Zone 2 explosion-proof certification (applicable to distribution in hazardous areas).

Configuration and operation points

1. Protection of fixed value configuration logic

The device supports configuring settings according to the "protection group" to meet different operating mode requirements (such as "normal operation", "maintenance mode", "backup power on/off"). The core configuration steps are as follows:

Enter the "Fixed Value Settings" menu (requires administrator privileges, password protection);

Select the type of protection object (such as "feeder protection" or "transformer protection"), and the system will automatically load the default protection logic template;

Adjust specific settings (such as overcurrent settings and action time limits), support real-time preview of the effective range of settings (to avoid exceeding the device's allowable values);

Save the set value and activate it (some models require restarting the device or manually switching the protection group), and automatically record the set value modification event after activation.

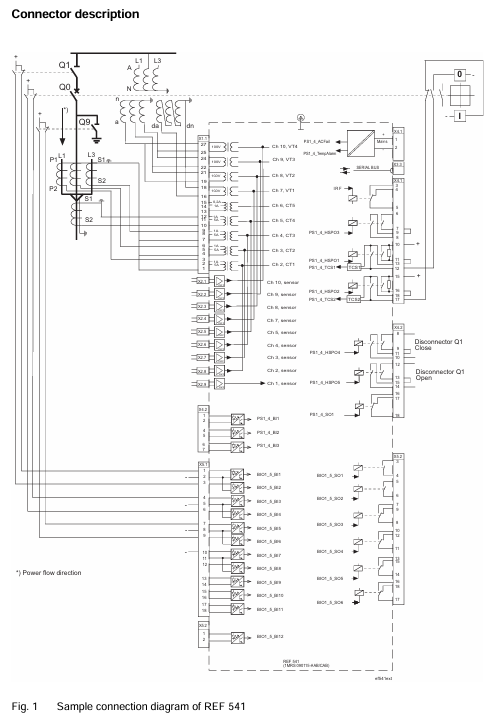

2. Installation and wiring specifications

Installation method: Using standard DIN rail installation (35mm rail), compact size (width x height x depth about 90 x 140 x 180mm), suitable for installation inside 19 inch distribution cabinet doors or cabinets, with a reserved installation spacing of ≥ 50mm (for heat dissipation);

Wiring requirements:

Current circuit: Attention should be paid to the polarity of the CT secondary side wiring ("P1" in "P2" out) to avoid reverse connection and protection misoperation;

Voltage circuit: PT wiring needs to distinguish between line voltage (such as Uab, Ubc) and phase voltage (such as Ua, Ub, Uc) to ensure correct measurement and protection logic;

Communication circuit: RS485 uses shielded twisted pair cables (shielded layer single ended grounding), Ethernet uses CAT5e or above network cables, and the distance between strong current cables is ≥ 100mm to reduce interference.

Maintenance and troubleshooting

1. Regular maintenance plan

Daily inspection (daily/weekly): Check the LCD display screen to confirm that there are no fault alarms (such as "CT disconnection" or "PT voltage loss"); Check the status of the indicator lights (green power light on, flashing running light is normal);

Regular maintenance (monthly/quarterly): Clean the surface dust of the device (wipe with a dry dust-free cloth); Check the tightness of the wiring terminals (to avoid looseness and poor contact); Export event records and measurement data through the upper computer, analyze equipment operation trends;

Annual maintenance: Testing the accuracy of protection settings (using relay protection testers to simulate fault signals and verify the correctness of actions); Check the tripping outlet relay contacts (measure the continuity of the contacts with a multimeter); Upgrade device firmware (download the latest version from ABB's official website and upgrade via USB or Ethernet).

2. Common faults and solutions

Possible causes and solutions for the fault phenomenon

The power light is not on, the power supply is not powered, the power module is faulty, and the wiring is loose. Check the output of the 220V/110V DC power supply; Re plug and unplug the power supply wiring; Replace the power module

The protection device refuses to operate and the protection setting is incorrect, the CT/PT wiring is reversed, and the tripping circuit fault occurs. Re check the protection setting (such as whether the overcurrent setting is lower than the fault current); Check CT/PT polarity; Test the tripping outlet relay (simulate the tripping signal with a tester)

Communication interruption (with upper computer), communication line failure, IP address conflict, protocol mismatch, replacement of communication line; Reconfigure RS485 address/IP address (to avoid conflicts); Confirm that the communication protocol is consistent (such as Modbus RTU slave address)

Display the "CT disconnection" alarm for CT circuit open circuit, CT fault, and internal sampling circuit fault. Check the CT secondary side wiring (whether it is open circuit); Measure the CT circuit resistance with a multimeter (normally ≤ 5 Ω); Contact ABB for after-sales inspection of the sampling circuit of the device

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923