K-WANG

Baldor FlexDrive II Servo Drive Technology Explanation and Application Guide

Baldor FlexDrive II Servo Drive Technology Explanation and Application Guide

The Baldor FlexDrive II series AC servo drive is a high-performance, compact single axis drive solution widely used for precision motion control in industrial automation. This article is based on the official technical manual and provides a comprehensive analysis of the technical characteristics, installation configuration, operation programming, and typical applications of this series of products, providing practical references for engineers and technicians.

Product Overview and Core Features

FlexDrive II is a servo drive series launched by Baldor (now a brand under ABB Group), offering continuous current levels from 2.5A to 27.5A and supporting single-phase 115V/230V or three-phase 230-460V power inputs. Its design combines flexibility and high performance, suitable for precise control of rotary and linear motors.

The main features include:

Multiple feedback support: compatible with Resolvers, Incremental Encoders, EnDat, and Hiperface Absolute Encoders.

Comprehensive control modes: Supports torque (current) control, speed control, and position control (including pulse direction input).

Integrated Motion Controller (Flex+Drive II): Built in programmable Mint language controller, supporting preset motion, point-to-point positioning, electronic gear synchronization, and other functions.

Rich I/O interfaces: Provides 8 digital inputs, 3 digital outputs, 1 analog input, 1 relay output, and supports RS232/RS485 communication.

Modular options: Factory installation options can be used to expand fieldbus functions such as CANopen, DeviceNet, Profibus, etc.

Hardware installation and electrical connection

2.1 Mechanical installation requirements

The driver should be installed vertically on a non flammable surface, with a minimum distance of 13mm left and right, and a ventilation space of 50mm up and down. The ambient temperature should be between 0 ° C and 40 ° C, and the humidity should be ≤ 90% without condensation.

2.2 Power and motor wiring

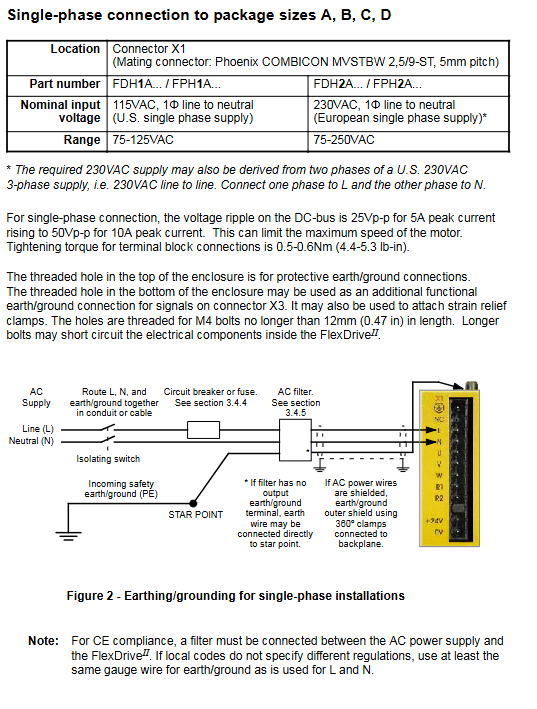

Single phase models (packaging A, B, C, D): Connect L, N, and protective ground wire through X1 connector.

Three phase models (packaged E, G, H): Connect L1, L2, L3, and PE through X1A connectors.

Motor connection: The UVW output must be consistent with the corresponding phase sequence of the motor, and it is recommended to use shielded twisted pair cables with a maximum length of 30.5m.

Regenerative resistor: Models of 7.5A and above require an external regenerative resistor to absorb braking energy and avoid DC bus overvoltage.

2.3 Control Power and Enable

Some models require an external 24VDC control power supply (FDHxxxxxx-xxx3) to maintain the logic circuit and I/O status. Driver enablement must simultaneously meet the following requirements:

Apply a 24V enable signal between pins 7-9 of X3;

DIP switch SW1-8 is set to ON;

Enable commands through software or hardware input.

Feedback and Communication Configuration

3.1 Feedback Interface (X8)

Rotary transformer: 9-pin D-Sub, supports 14 bit resolution, equivalent to 4096PPR.

Encoder: 15 pin high-density D-Sub, supporting A/B/Z differential signals and Hall input.

Absolute value encoder: Supports EnDat and Hiperface protocols, capable of reading and writing multi turn position data.

3.2 Communication Interface

X6: Can be configured as RS232 (point-to-point) or RS485/422 (multi station network), supporting up to 57.6kbps.

Fieldbus options: Supports CANopen, DeviceNet, and Profibus DP through factory installed modules.

Software Configuration and Sports Programming

4.1 Mint WorkBench Tool

PC configuration software, providing:

Commissioning Wizard: Automatically identify motor parameters and complete closed-loop tuning.

Parameter tool: Set control mode, proportional integral derivative (PID) gain, soft limit, etc.

I/O mapping tool: Configure the functional allocation of digital inputs/outputs, such as limit switches, enablement, alarms, etc.

Preset movements and PLC tasks: 16 sets (expandable to 256 sets) of preset movements can be defined, and automated sequences can be implemented through conditional logic.

4.2 Control mode selection

Torque mode: directly controls the output torque of the motor, suitable for tension and pressure control.

Speed mode: Closed loop speed control, suitable for conveying and rotating mechanisms.

Position mode: Supports advanced positioning functions such as preset motion, electronic gears, and following the main encoder.

Safety and Fault Diagnosis

5.1 Safety precautions

Only professionals are allowed to install and debug.

The driver must be reliably grounded, and there is a risk of electric shock at the high-voltage terminals.

Braking resistors may generate high temperatures and should be kept away from flammable materials.

The emergency stop signal should not rely solely on the stop input of the driver, and redundant safety circuits should be designed.

5.2 Status indicator lights and fault codes

The driver panel is equipped with LED status display, which can indicate:

Ready/Running: Display "-" or speed value.

Fault: Flashing characters indicate specific errors, such as "E." for overcurrent and "I." for overvoltage.

Detailed errors can be queried through the Mint WorkBench error log or keywords (AXISERROR, DRIVE ERROR).

Typical application areas

The FlexDrive II series is suitable for:

Machine tool feed axis and spindle control

Positioning and synchronization of packaging machinery

Robot joint drive

Winding and tension control in the printing and textile industries

Precision positioning platform in semiconductor equipment

Conclusion

The Baldor FlexDrive II servo drive is a reliable choice in the field of industrial motion control due to its flexible configuration, powerful control performance, and rich expansion options. Combining Mint programming environment and modular design, it can meet both simple speed control requirements and complex multi axis coordinated motion. Proper installation, reasonable configuration, and regular maintenance can ensure the long-term stable operation of the system.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923